A kind of glass-ceramic material and its preparation method and application in semiconductor devices

A technology of glass-ceramics and glass, which is applied in branch office equipment, electrical components, telephone structures, etc., to achieve the effect of improving transparency, impact resistance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] This embodiment provides a series of glass-ceramic, which is composed of the following components (weight fraction, the same below): 2.0wt%Li 2 O, 25.5wt%A 2 lO 3 , 51.5%wtSiO 2 , 0.5wt%CaO, 0.5wt%SrO, 3.0wt%ZnO, 8.1wt%MgO, 0.5wt%BaO, 0.4wt%K 2 O, 1.0wt%Na 2 O, 5.0wt%ZrO 2 , 0.1wt%Y 2 o 3 , 0.4wt%Sb 2 o 3 , 0.4wt%NaCl, 0.5wt%SnO 2、 0.3%TiO 2 , 0.2%P 2 o 5、 0.1wt% La 2 o 3 .

[0074] The preparation process is as follows:

[0075] (1) Mix the components and melt at 1655°C for 10 hours, then cool at 1460°C for 3 hours, and then cast to obtain ordinary glass.

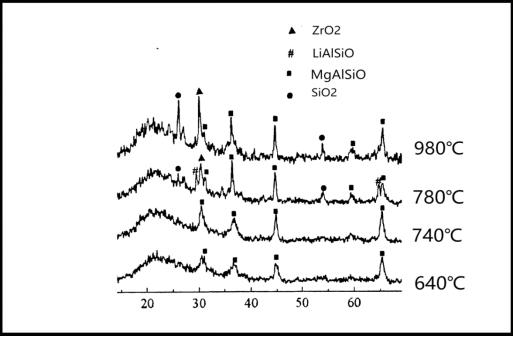

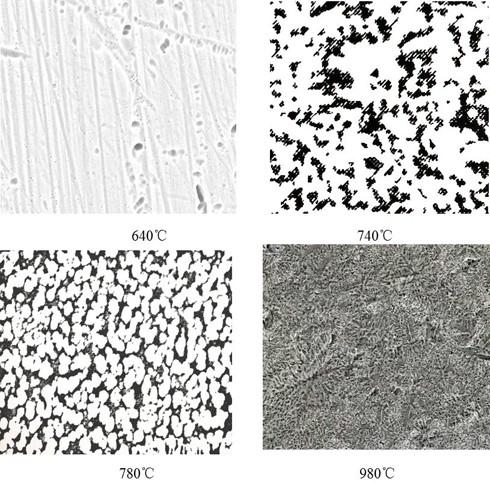

[0076] (2) Crystallized glass is obtained by crystallizing ordinary glass. The crystallization process is divided into three stages. The temperature of the first stage is 640°C for 2 h, and the temperature of the second stage is 710°C for 2 hours. 1 h, the third stage was 780 °C, and the time was 2 h; annealing treatment was performed after the crystallization treatment, and the temperature of anne...

Embodiment 2

[0080]This embodiment provides a glass-ceramic, which is composed of the following components: 51.7wt% SiO 2 , 25.1wt% Al 2 o 3 , 3.0wt% ZnO, 5.0wt% ZrO 2 , 0.6wt% Y 2 o 3 , 0.3wt% Sb 2 o 3 , 1.0wt% BaO, 0.5wt% SrO, 1wt% La 2 o 3 , 5.5wt%Na 2 O, 1.0wt%K 2 O, 0.5wt%Li 2 O, 0.5wt% CaO, 0.5wt% SnO 2 , 0.3 wt % TiO 2 , 0.2%P 2 o 5、 Composition of 3.0 wt% MgO, 0.3 wt% NaCl.

[0081] The preparation process is as follows:

[0082] (1) The components were mixed and melted at 1650°C for 8.3 hours, then cooled at 1450°C for 2 hours, and then cast to obtain ordinary glass.

[0083] (2) Crystallized glass is obtained by crystallizing ordinary glass. The crystallization process is divided into two stages. The temperature of the first stage is 640°C for 3 h, and the temperature of the second stage is 750°C for 3 hours. 2 h, annealing treatment was carried out after crystallization treatment, the temperature of annealing treatment was 578°C, and the time was 2.5 h.

[0084...

Embodiment 3

[0086] This embodiment provides a glass-ceramic, which is composed of the following components: 45.2 wt% SiO 2 , 33.1 wt%Al 2 o 3 , 1.0 wt% ZnO, 4.0 wt% ZrO 2 , 0.5 wt% Y 2 o 3 , 0.2 wt% Sb 2 o 3 , 0.6 wt% BaO, 0.5 wt% SrO, 0.8 wt% La 2 o 3 , 3.5 wt% Na 2 O, 1.2 wt%K 2 O, 1.5 wt% Li 2 O, 0.4 wt% CaO, 0.5 wt% SnO 2 , 0.3 wt % TiO 2 , 0.4 wt % P 2 o 5 , 6.0 wt% MgO, 0.3wt% NaCl composition.

[0087] The preparation process is as follows:

[0088] (1) The components were mixed and melted at 1660°C for 8 hours, then cooled at 1450°C for 2 hours, and then cast to obtain ordinary glass.

[0089] (2) Crystallized glass is obtained by crystallizing ordinary glass. The crystallization process is divided into three stages. The temperature of the first stage is 620°C and the time is 1.5 h. The temperature of the second stage is 730°C and the time is After 1.5 h, annealing treatment is required after the crystallization treatment, the temperature of annealing treatment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com