Organic silicon modified epoxy coating with anticorrosion and transition connection functions and preparation method thereof

A technology of transition connection and epoxy coating, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem that the adhesion behavior of anti-corrosion primers is difficult to meet practical applications, achieve excellent interface bonding, and enhance crosslinking Density, the effect of solving poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

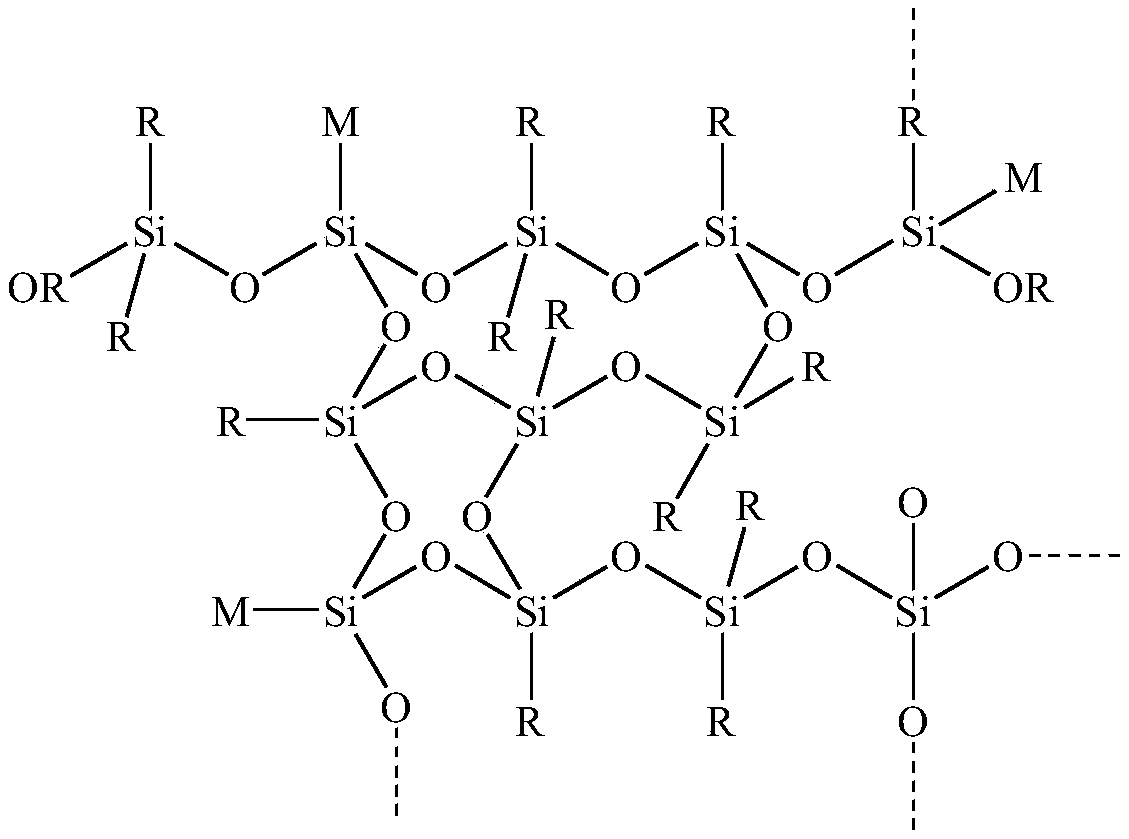

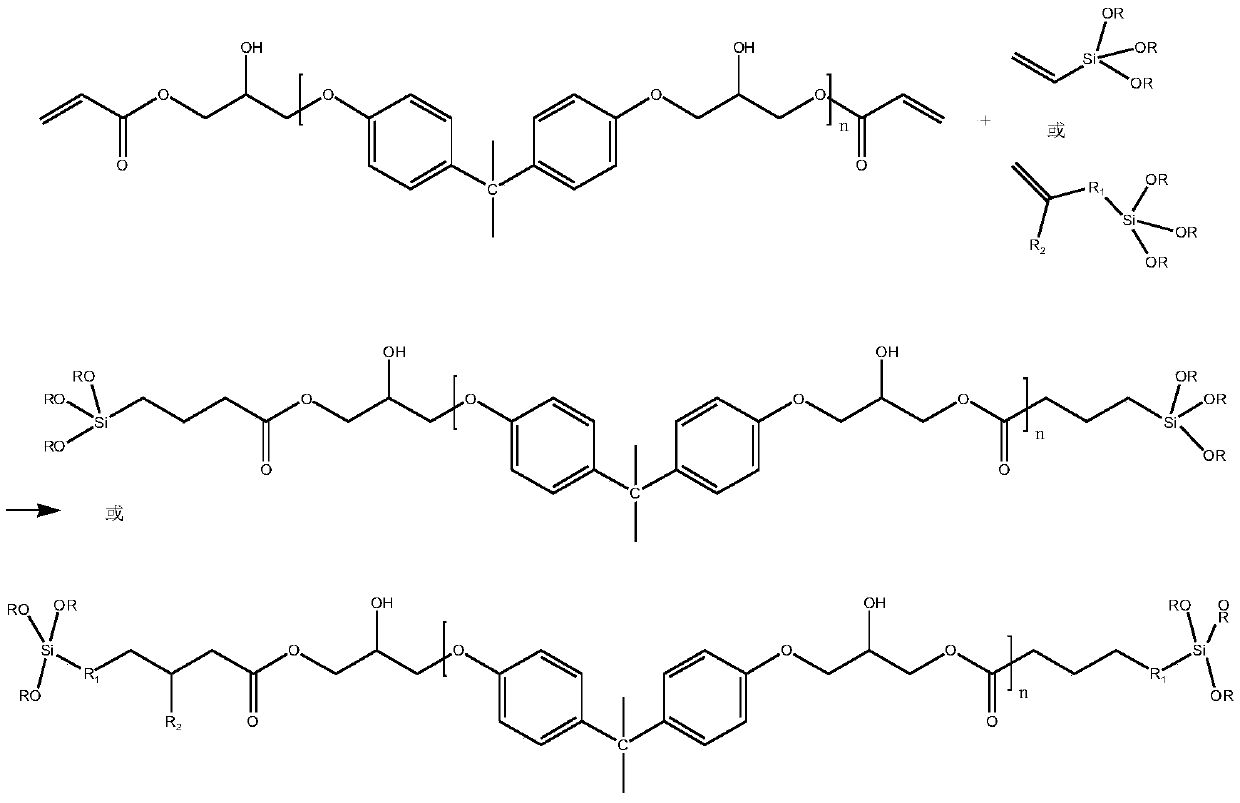

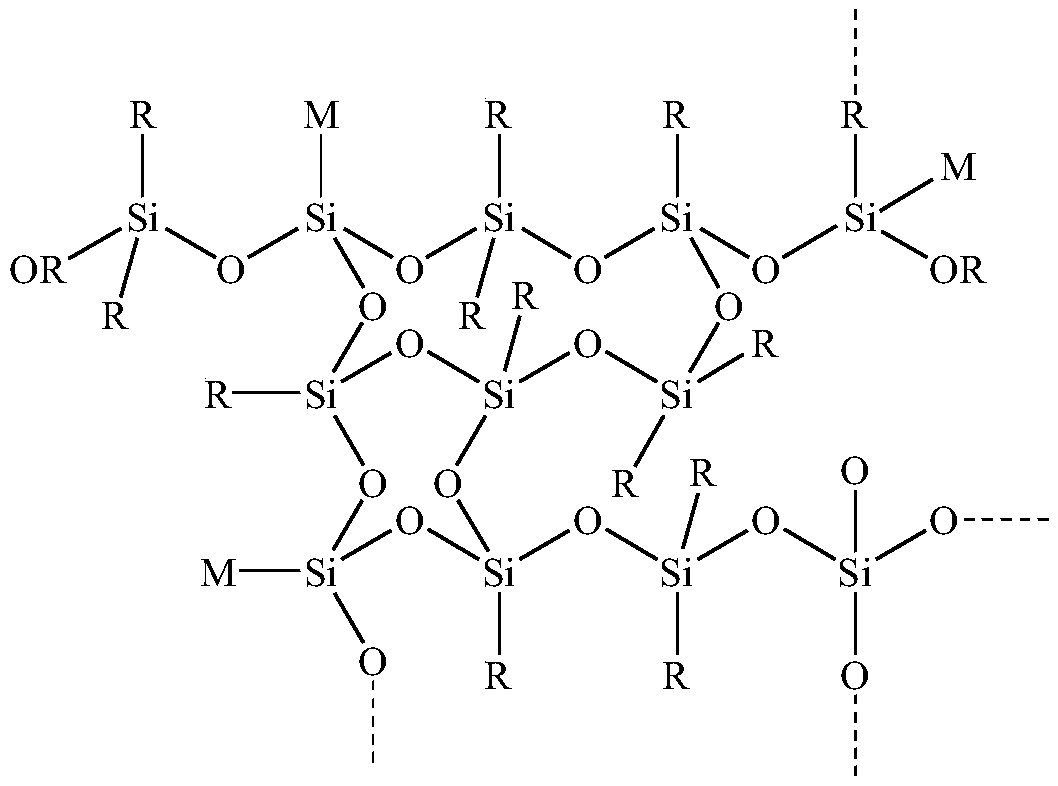

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: in the 500mL four-neck flask that stirring device, condensing device, thermometer are housed, add the mixed solvent of 60.5g xylene / n-butanol (the mass ratio of xylene and n-butanol is 1:1), Nitrogen was passed through the reaction system, the temperature was raised to 90°C, and 55g of bisphenol A epoxy vinyl ester resin, 25.5g of 3-isobutallyltrimethoxysilane and 0.7g of azobisisobutyronitrile were weighed and mixed uniformly, and placed in Evenly added dropwise to the reaction system within 2 hours, after the dropwise addition was completed, after 1 hour of heat preservation, continue to dropwise add a mixed solution of 0.1g of azobisisobutyronitrile and 4.5g of xylene within 0.5h, keep heat for 2h, cool down and discharge, and obtain Pale yellow silicone modified epoxy vinyl ester resin.

Embodiment 2

[0018] Example 2: In a 500mL four-neck flask equipped with a stirring device, a condensing device, and a thermometer, add a mixture of 50.5g xylene / methyl isobutyl ketone (the mass ratio of xylene to butyl acetate is 1:1) Solvent, blow nitrogen into the reaction system, heat up to 110°C, and weigh 65g of bisphenol F epoxy vinyl ester resin, 25.5g of vinyltrimethoxysilane and 0.8g of tert-butyl peroxy-2-ethylhexanoate Mix evenly, and evenly add dropwise to the reaction system within 2 hours. After the dropwise addition is completed, keep warm for 1 hour, continue to drop the mixed solution of 0.1g azobisisobutyronitrile and 4.5g xylene within 0.5h, keep warm for 2h, A light yellow silicone-modified epoxy vinyl ester resin was obtained.

Embodiment 3

[0019] Example 3: In a 500mL four-neck flask equipped with a stirring device, a condensing device, and a thermometer, add 50.5g xylene / methyl isobutyl ketone (the mass ratio of xylene to methyl isobutyl ketone is 1: 1) Mixed solvent, blow nitrogen to the reaction system, heat up to 90°C, weigh 55g of novolac epoxy vinyl ester resin, 24.5g of 3-propenylpropyltrimethoxysilane and 0.7g of azobisisovaleronitrile and mix evenly , and evenly added dropwise to the reaction system within 2 hours. After the dropwise addition was completed and kept warm for 1 hour, continue to add a mixed solution of 0.1g azobisisovaleronitrile and 4.5g xylene dropwise within 0.5h, keep warm for 2 hours, and obtain light Yellow silicone modified epoxy vinyl ester resin.

[0020] The preparation method of silicone modified epoxy coating is shown in Table 1.

[0021] Table 1

[0022]

[0023]

[0024] Preparation of silicone-modified epoxy coating with both anti-corrosion and transition connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com