A thermally conductive resin composition and preparation method thereof

A heat-conducting resin and composition technology, applied in the field of potting glue, can solve the problems of thermal conductivity, insulation, manufacturability and practical balance, and achieve the effect of increasing the content of heat-conducting fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

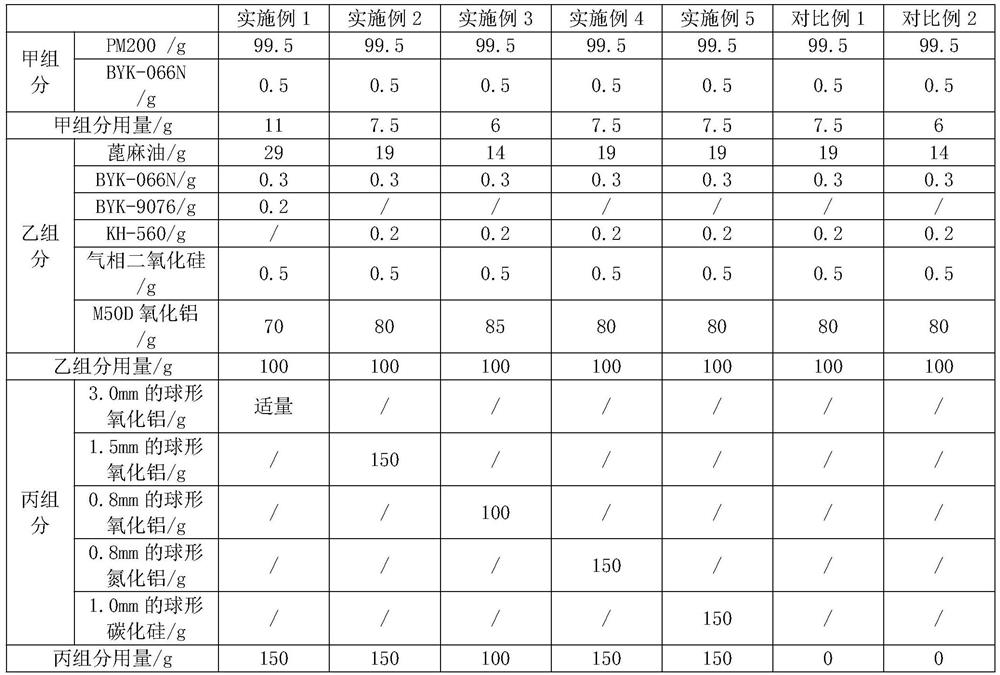

Embodiment 1

[0043]A thermally conductive resin composition is prepared from the following raw materials: 11 grams of component A, 100 grams of component B and an appropriate amount of component C.

[0044] The preparation of component A is: after mixing 99.5 grams of PM200 and 0.5 grams of BYK-066N, vacuum defoaming at 60°C for 30 minutes, and then lowering to 25°C to prepare.

[0045] The preparation of component B is as follows: 29 grams of castor oil, 0.3 grams of BYK-066N, 0.2 grams of BYK-9076, 0.5 grams of fumed silica, and 70 grams of M50D alumina are dispersed at high speed for 20 minutes, dehydrated in a vacuum at 120 ° C for 2 hours, and reduced prepared at room temperature.

[0046] The preparation of component C is prepared by drying spherical alumina with a diameter of 3.0 mm at 110° C. for 5 hours, and then reducing the nitrogen protection to room temperature.

[0047] A preparation method of a thermally conductive resin composition is as follows: manually stirring 11 grams...

Embodiment 2

[0049] The thermal resin composition is prepared from the following raw materials: 7.5 grams of component A, 100 grams of component B and 150 grams of component C.

[0050] The preparation of component A is: after mixing 99.5 grams of PM200 and 0.5 grams of BYK-066N, vacuum defoaming at 60°C for 30 minutes, and then lowering to 25°C to prepare.

[0051] The preparation of component B is: 19 grams of castor oil, 0.3 grams of BYK-066N, 0.2 grams of KH-560 (γ-(2,3-glycidoxy)propyltrimethoxysilane), 0.5 grams of gas-phase dioxide Silicon and 80 grams of M50D alumina were dispersed at high speed for 20 minutes, dehydrated in vacuum at 120°C for 2 hours, and cooled to room temperature to prepare component B.

[0052] The preparation of the C component is as follows: drying spherical alumina with a diameter of 1.5 mm at 110° C. for 5 hours, and nitrogen protection is lowered to room temperature to become the C component.

[0053] A preparation method of a thermally conductive resin ...

Embodiment 3

[0055] A thermally conductive resin composition is prepared from the following raw materials: 6 grams of component A, 100 grams of component B and 100 grams of component C.

[0056] The preparation of component A is: after mixing 99.5 grams of PM200 and 0.5 grams of BYK-066N, vacuum defoaming at 60°C for 30 minutes, and then lowering to 25°C to prepare.

[0057] The preparation of component B is as follows: 14 grams of castor oil, 0.3 grams of BYK-066N, 0.2 grams of KH-560, 0.5 grams of fumed silica, and 85 grams of M50D alumina are dispersed at high speed for 20 minutes, dehydrated in vacuum at 120 ° C for 2 hours, and then reduced to room temperature to prepare component B.

[0058] The preparation of the C component is as follows: drying spherical alumina with a diameter of 0.8 mm at 110° C. for 5 hours, and nitrogen protection is lowered to room temperature to become the C component.

[0059] A preparation method of a thermally conductive resin composition is as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com