Waterproof structure of drainage type tunnel primary support system and construction method thereof

A technology for primary support and waterproof structures, applied in tunnels, tunnel linings, drainage, etc., can solve the problems of low cost, poor implementation effect, and inability to effectively release the water pressure on the back of the wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

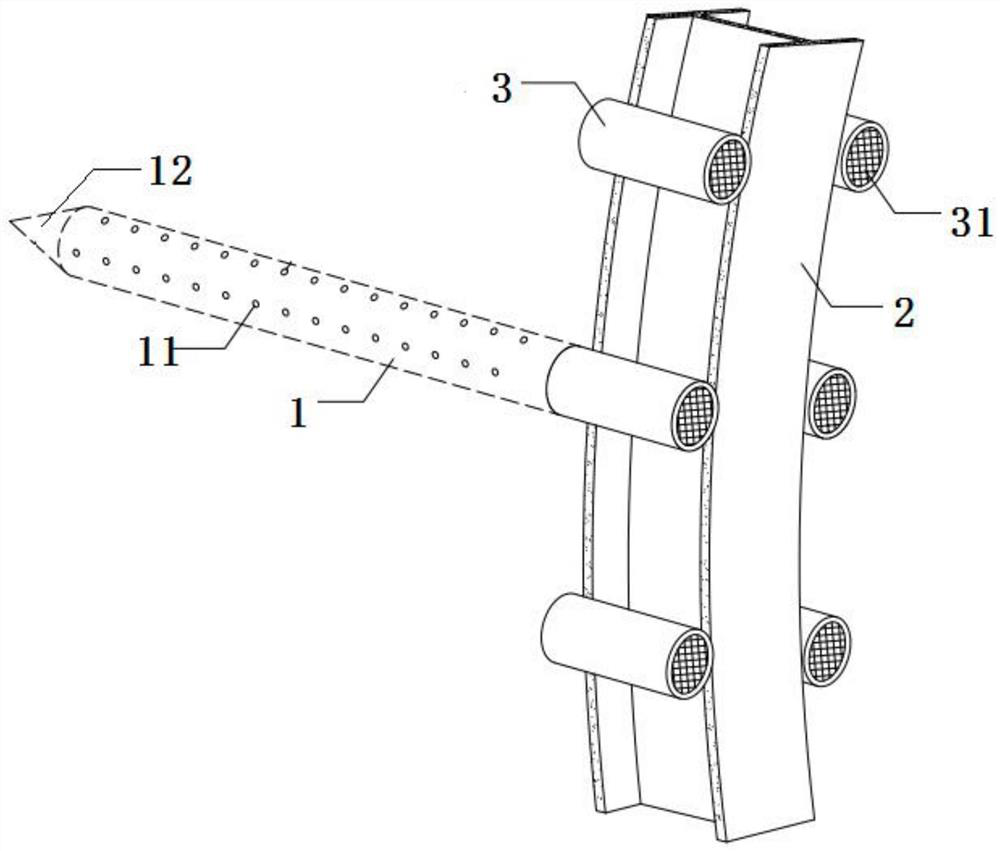

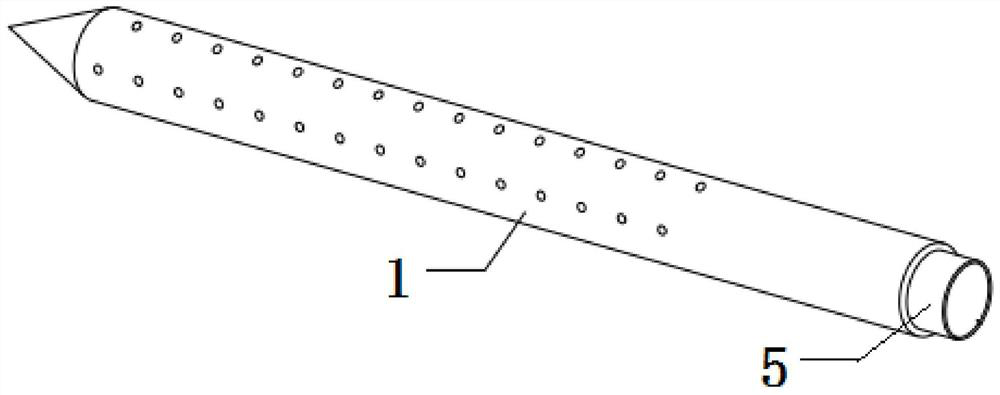

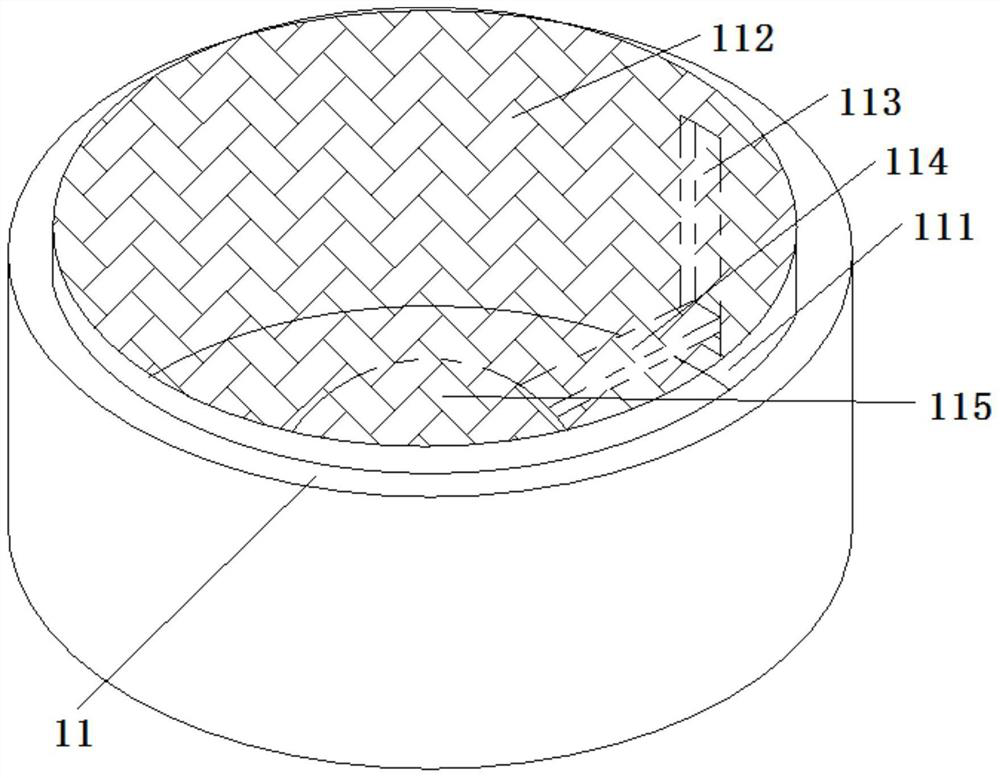

[0041] see figure 2 , 6 , a waterproof structure for the primary support system of a drainage type tunnel, comprising an outer tube 1 and an inner tube 5, the inner tube 5 can be extended into the inside of the outer tube 1 and pulled out, and the outer tube 1 The inner wall is in contact with the outer wall of the inner pipe 5, and the outer pipe 1 is provided with a water inlet hole 11, and the inner pipe 5 can rotate in the outer pipe 1 to realize the connection between the water inlet hole 11 and the inner pipe 1. The water inlet 52 on the pipe 5 is selectively communicated, and the inner pipe 5 is provided with a Tesla valve-shaped diversion chamber 51 communicating with the water inlet 52 of the inner pipe 5, and the diversion chamber 51 can be Under the action of speeding up the water flow out of the outer tube 1.

[0042] Wherein, the contact between the inner wall of the outer tube 1 and the inner wall of the inner tube 5 can prevent water from entering from the wate...

Embodiment 2

[0066] Embodiment 2 is a construction method for a waterproof structure of a drainage type tunnel primary support system proposed on the basis of Embodiment 1, and the steps are as follows:

[0067]S1: Insert the inner tube 5 into the inside of the outer tube 1, so that the water inlet 11 on the outer tube 1 and the water inlet 52 on the inner tube 5 are in a closed state; Pipe 1 is drilled into the rock formation at a certain angle;

[0068] S2: Rotate the inner tube 5 again, so that the water inlet 52 communicates with the water inlet hole 11 on the outer tube 1, and water can flow into the diversion chamber 51 of the inner tube 5;

[0069] S3: Fix the outer pipe 1, pull out the inner pipe 5 after no water flows out from the inner pipe 5; then inject grout into the outer pipe 1.

[0070] In actual implementation, specifically:

[0071] S1: The surface of the tunnel is excavated and cleared, the initial spraying in the tunnel (the initial support is divided into initial spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com