1000mm last-stage moving blade for 3000rpm full-rotation-speed steam turbine

A technology of steam turbines and moving blades, which is applied in the direction of machines/engines, blade support components, mechanical equipment, etc., and can solve the problem that the last-stage long blades cannot meet the needs of units of different capacity levels, so as to enhance market competitiveness, improve efficiency, The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

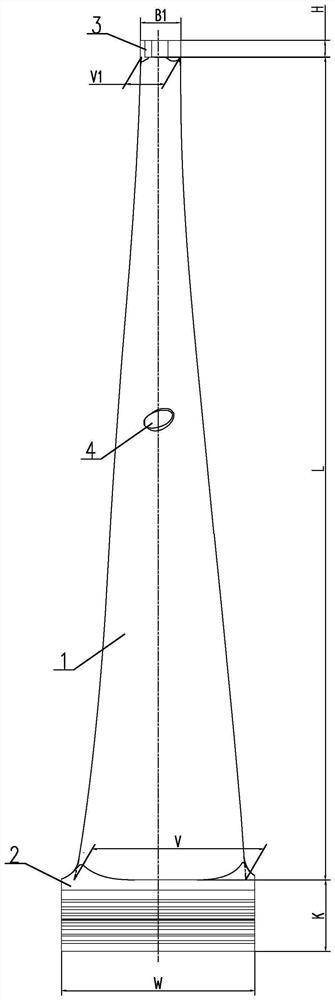

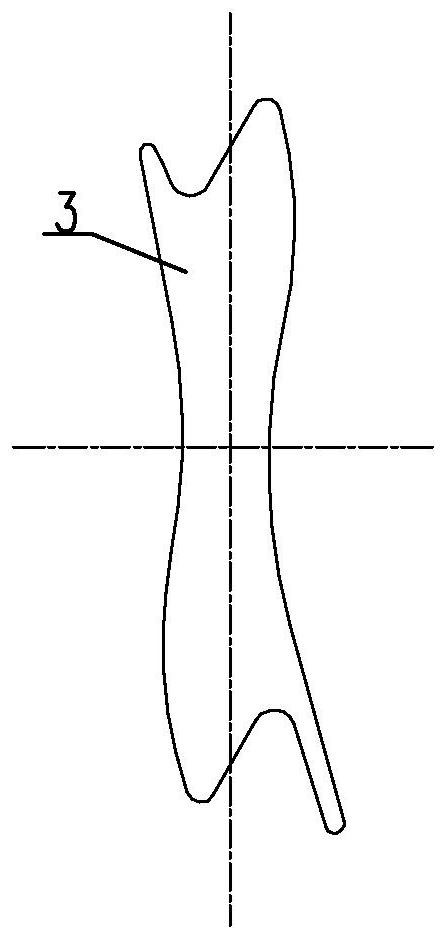

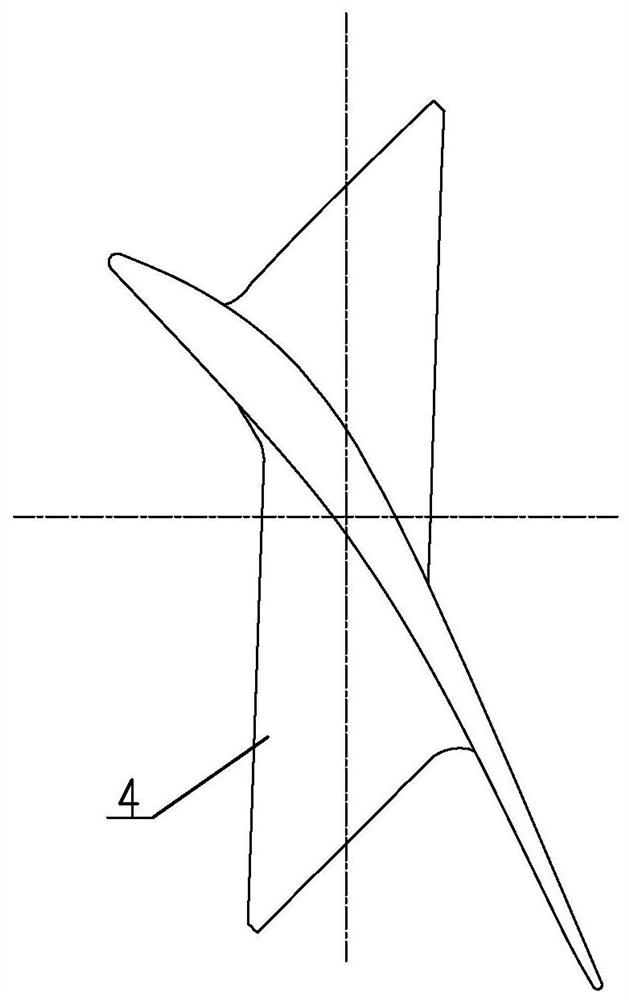

[0016] Specific implementation mode one: combine Figure 1 ~ Figure 4 Describe this embodiment, this embodiment is made up of blade working part 1, blade root 2, shroud 3 and boss tie bar 4, and shroud 3, blade work part 1, blade root 2 and boss tie bar 4 are from top to bottom The lower die is forged into one, and the profile of the working part 1 of the blade is a variable cross-section twisted blade, that is, there is a relative twist between two adjacent sections, and the cross-sectional area of the working part 1 of the blade decreases gradually from the root to the top; the height of the working part 1 of the blade is L is 1000mm, the axial width V of the root of the blade working part 1 is 206.83mm, the root diameter of the blade working part 1 is 1500mm, and the exhaust area of the blade working part 1 is 3.37m 2 , the thickness H of the shroud 3 is 22mm, and the axial distance B1 of the working surface of the shroud 3 is 49.47mm.

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 , Figure 4 , Figure 5 and Figure 6 To illustrate this embodiment, the variation range from the root axial width V of the blade working part 1 to the top axial width V1 of the blade working part 1 in this embodiment is 206.83 mm to 47.68 mm, and the variation range of the chord length b is 208.99 mm to 208.99 mm. 171.74mm, installation angle β y The variation range of the maximum profile thickness T is 23.2mm to 6.37mm, the variation range of the inlet angle α is 56.72°~161.1°, and the variation range of the outlet angle θ is 38.32°~24.9° . By adopting the above structural parameters, the blades can be easily assembled while ensuring that the outer structure dimensions of the blades meet the design requirements. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: combination figure 1 , Figure 4 , Figure 5 and Figure 6 Describe this embodiment, the height L of blade working part 1 of this embodiment is respectively 0mm, 200mm, 400mm, 650mm, 900mm, 1000mm, and the corresponding axial width V of blade working part 1 is respectively: 206.83mm, 164.31mm , 129.74mm, 88.43mm, 53.79mm, 47.68mm, the corresponding chord length b is respectively: 208.99mm, 169.27mm, 152.28mm, 157.9mm, 168.28mm, 171.74mm, and the corresponding installation angle β y They are respectively: 82.3°, 76.49°, 58.56°, 33.91°, 18.33°, 15.84°, and the corresponding maximum thickness T of the molding line are: 23.2mm, 25.87mm, 22.24mm, 12.48mm, 8.16mm, 6.37 mm, the corresponding inlet angle α is respectively: 56.72°, 46.15°, 66.75°, 123.53°, 153.52°, 161.1°, and the corresponding outlet angle θ is respectively: 38.32°, 37.69°, 33.2°, 27.16 °, 24.49°, 24.9°. By adopting the above structural parameters, the blades can be easi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com