Production process control method and device based on automatic production line and computing equipment

A technology of automatic production line and production process, applied in the direction of comprehensive factory control, comprehensive factory control, program control, etc., can solve problems affecting the use efficiency of automatic production lines, and achieve the effect of improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

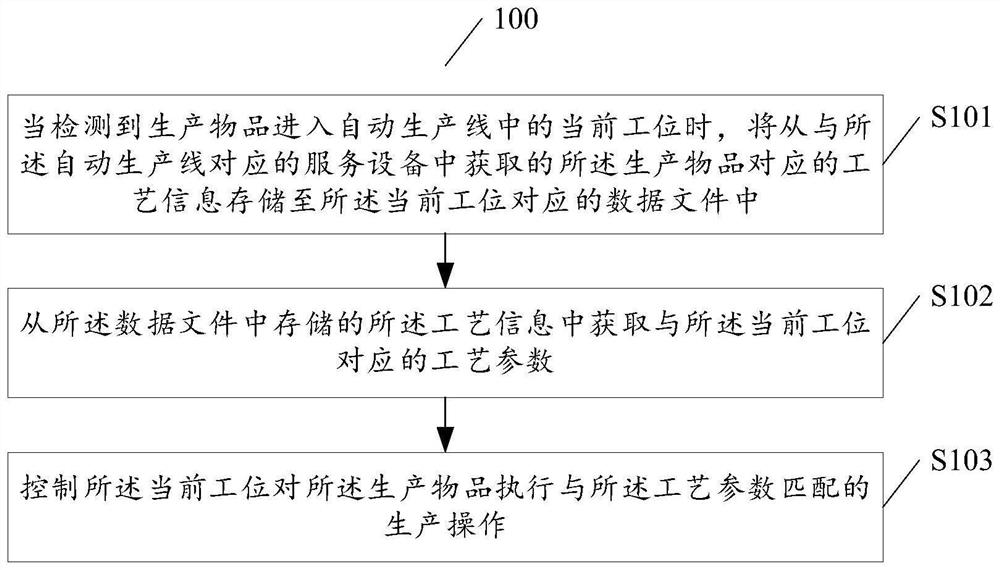

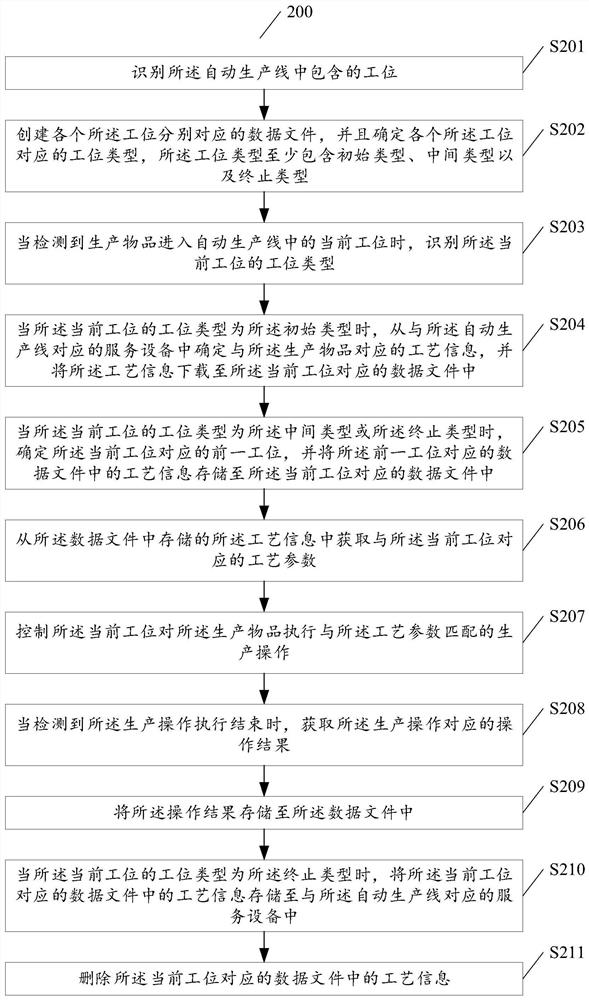

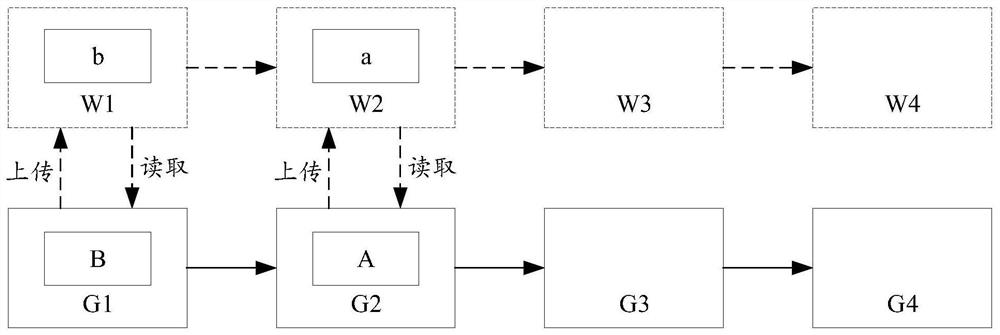

Method used

Image

Examples

Embodiment approach

[0101] As an optional implementation, the device may also include:

[0102] The second acquiring unit is configured to acquire after the first control unit controls the current station to perform a production operation matching the process parameters on the production item and when it is detected that the execution of the production operation ends. The operation result corresponding to the production operation;

[0103] The second storage unit is used for storing the operation result in the data file.

[0104] Wherein, implementing this embodiment, the operation results performed by the current station can be stored in the data file, and the process parameters that have been used in the process information contained in the data file can be marked through the operation results to avoid the process parameters being repeated. read, improving the accuracy of production operations performed by stations on production items.

[0105] As an optional implementation, the device may al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com