Processing method of PI reinforcement, manufacturing method of flexible circuit board with PI reinforcement and flexible circuit board

A technology of flexible circuit boards and processing methods, which is applied in printed circuit manufacturing, circuit bendable/stretchable parts, printed circuits, etc., and can solve problems such as ink falling off, ink brittle cracking and falling off, ink falling off easily, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

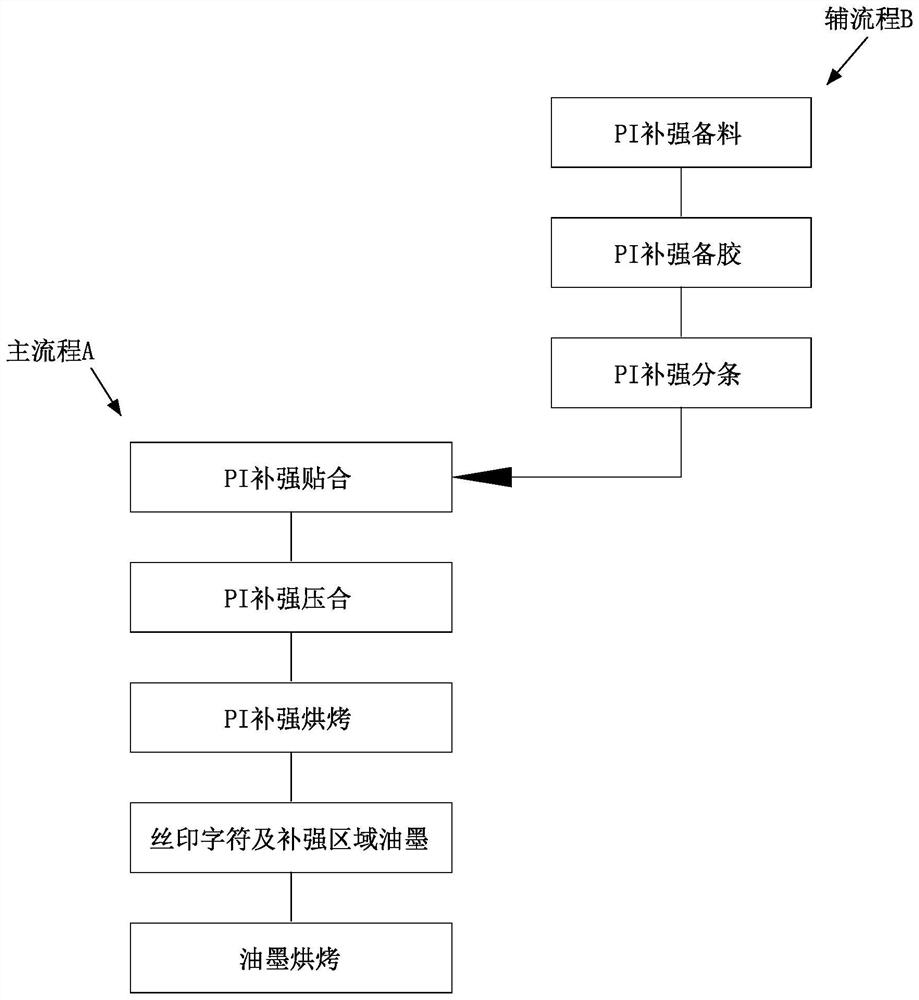

[0051] The present invention discloses a processing method for PI reinforcement, such as Figure 4 As shown in the auxiliary process B, it includes the following steps:

[0052] Step B1, PI reinforcement material preparation: prepare PI reinforcement materials required for processing;

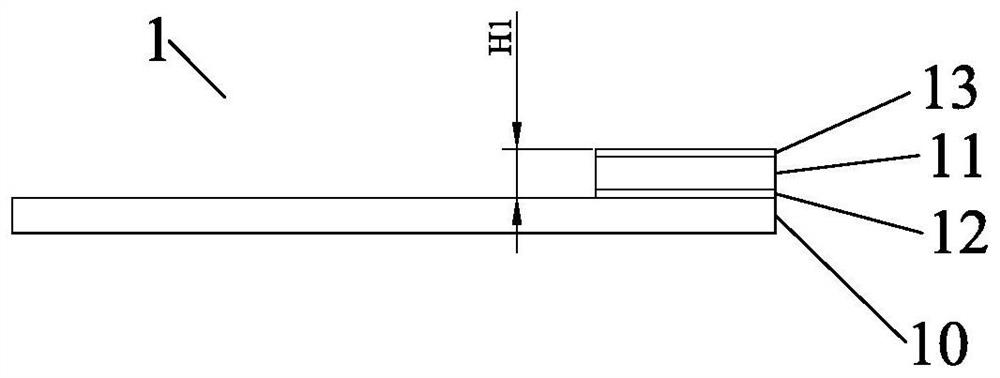

[0053] Step B2, preparing film on the top surface of PI reinforcement: hot rolling and bonding the cover film on the top surface of PI reinforcement 31, and the cover film has an adhesive layer;

[0054] Step B3, glue preparation on the bottom surface of PI reinforcement: hot rolling and lamination of pure rubber on the bottom surface of PI reinforcement, such as Image 6 shown;

[0055] Step B4, PI reinforcement slitting: the PI reinforcement obtained in step B3 is processed and slit into small rolls, which is convenient for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com