Tool steel hot-rolled steel strip and preparing method thereof

A technology of tool steel and steel strip, applied in the field of tool steel hot-rolled steel strip and its preparation, can solve the problems of low sharpness and high production cost, and achieve the effect of strong market competitiveness, low production cost and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

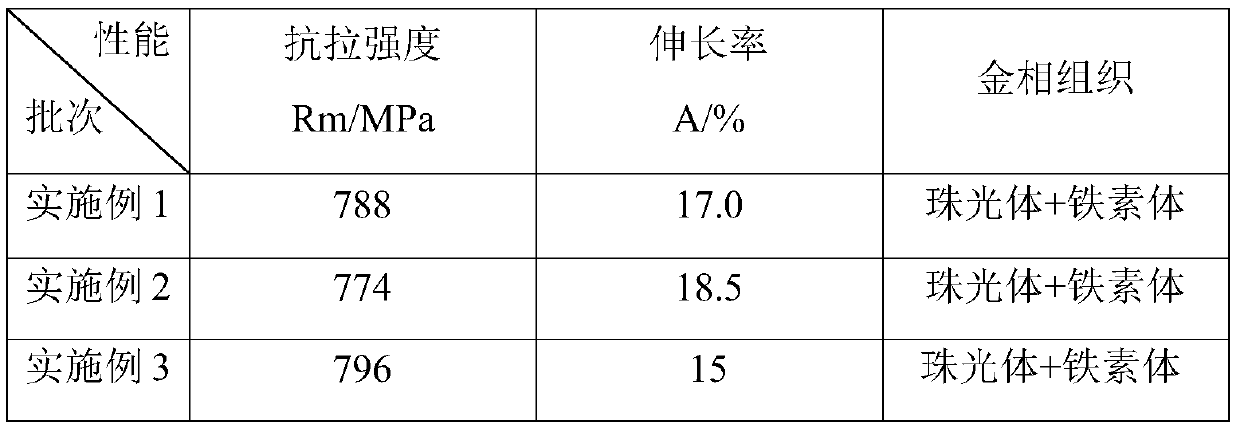

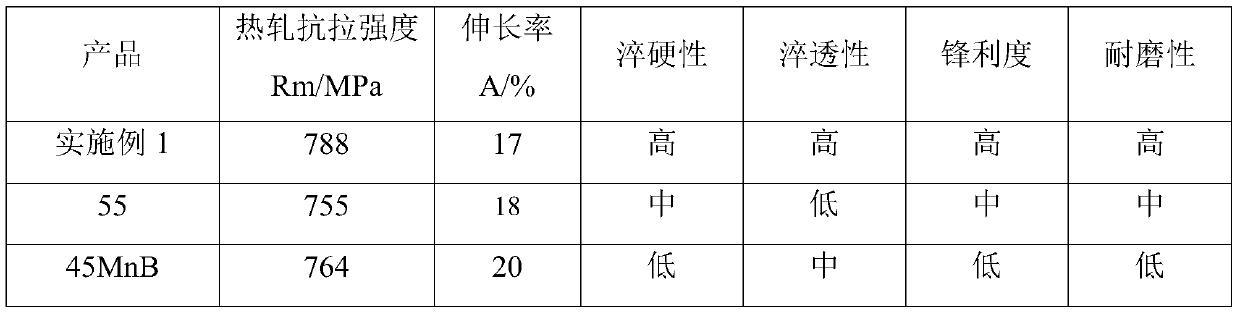

Examples

Embodiment 1

[0036] The following percentages are all in mass percent:

[0037] (1) Primary smelting of converter:

[0038] 27.35 tons of steel scrap are added to the molten iron, the total furnace capacity is 218 tons, and the mass percentage of S in the molten iron is 0.003%. Add active lime 35Kg / ton molten steel, limestone 17Kg / ton molten steel, raw dolomite 10Kg / ton molten steel, magnesite 14.5Kg / ton molten steel. The initial smelting was carried out in the primary smelting furnace for 21 minutes. After the initial smelting, the steel was released at a temperature of 1655° C. to obtain the primary molten steel, which was 192.4 tons.

[0039](2) Preliminary alloying

[0040] Add silicon manganese alloy (FeMn68Si18, comprise 68% manganese, 18% silicon, other impurity less than 5% and balance are iron) to the primary smelting molten steel that obtains in step (1), add-on is 7.5Kg / ton primary smelting Molten steel; then add aluminum and iron (FeAl40, containing 40% aluminum, less than ...

Embodiment 2

[0048] The following percentages are all in mass percent:

[0049] (1) Primary smelting of converter:

[0050] 28.15 tons of steel scrap are added to the molten iron, the total furnace capacity is 217 tons, and the mass percentage of S in the molten iron is 0.003%. Add active lime 34Kg / ton molten steel, limestone 16Kg / ton molten steel, raw dolomite 10Kg / ton molten steel, magnesite 15Kg / ton molten steel. In the primary smelting furnace, the initial smelting was carried out for 20 minutes. After the initial smelting, the steel was released at a temperature of 1647° C. to obtain the primary molten steel, which was 191.8 tons.

[0051] (2) Preliminary alloying

[0052] Add silicon manganese alloy (FeMn68Si18, comprise 68% manganese, 18% silicon, other impurity less than 5% and balance are iron) to the primary smelting molten steel that obtains in step (1), add-on is 7.5Kg / ton primary smelting Molten steel; then add aluminum and iron (FeAl40, containing 40% aluminum, less than ...

Embodiment 3

[0060] The following percentages are all in mass percent:

[0061] (1) Primary smelting of converter:

[0062] 26.05 tons of steel scrap are added to the molten iron, the total furnace capacity is 217 tons, and the mass percentage of S in the molten iron is 0.004%. Add active lime 35Kg / ton molten steel, limestone 16Kg / ton molten steel, raw dolomite 10Kg / ton molten steel, magnesite 15Kg / ton molten steel. In the primary smelting furnace, the initial smelting was carried out for 20 minutes. After the initial smelting, the steel was released at a temperature of 1649° C. to obtain the primary molten steel, which was 193.6 tons.

[0063] (2) Preliminary alloying

[0064] Add silicon-manganese alloy (FeMn68Si18, comprising 68% manganese, 18% silicon, other impurity less than 5% and balance are iron) to the primary smelting molten steel obtained in step (1), the addition is 7.7Kg / ton primary smelting Molten steel; then add aluminum and iron (FeAl40, containing 40% aluminum, less t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com