Low-pressure casting process for high-strength aluminum alloy casting for automobile

A technology of aluminum alloy castings and low-pressure casting, which is applied in the field of aluminum alloy castings, and can solve problems such as easy residual metal liquid and quality reduction of cast-molded workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

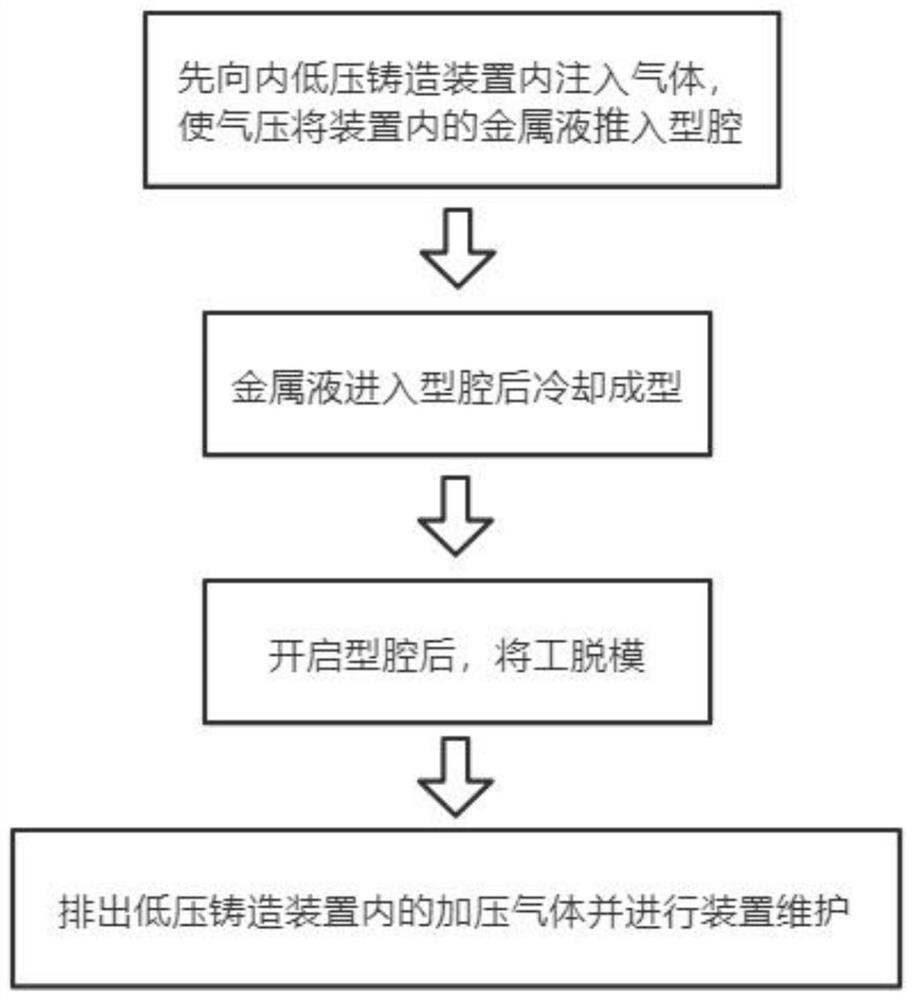

[0042] see Figure 1-3 , a high-strength low-pressure casting process of aluminum alloy castings for automobiles, the specific process is:

[0043] S1, first inject gas into the inner low-pressure casting device, so that the air pressure pushes the molten aluminum in the device into the cavity;

[0044] S2, after the liquid aluminum enters the cavity, it is cooled and formed;

[0045] S3, after opening the cavity, demoulding the worker;

[0046]S4, discharging the pressurized gas in the low-pressure casting device and performing device maintenance.

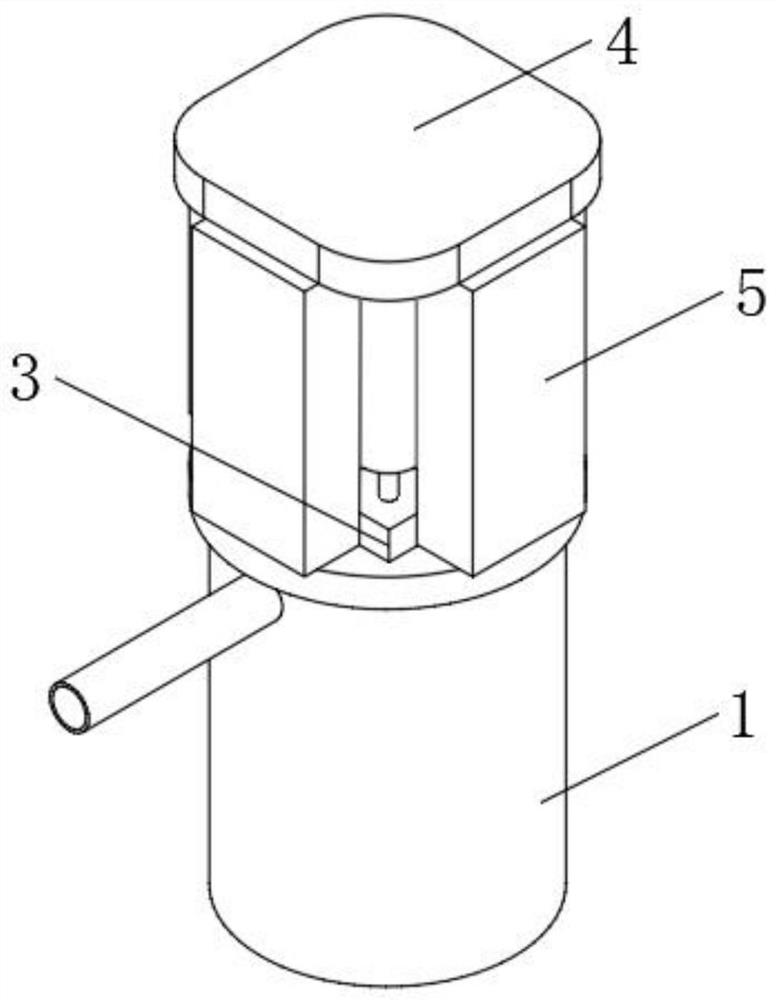

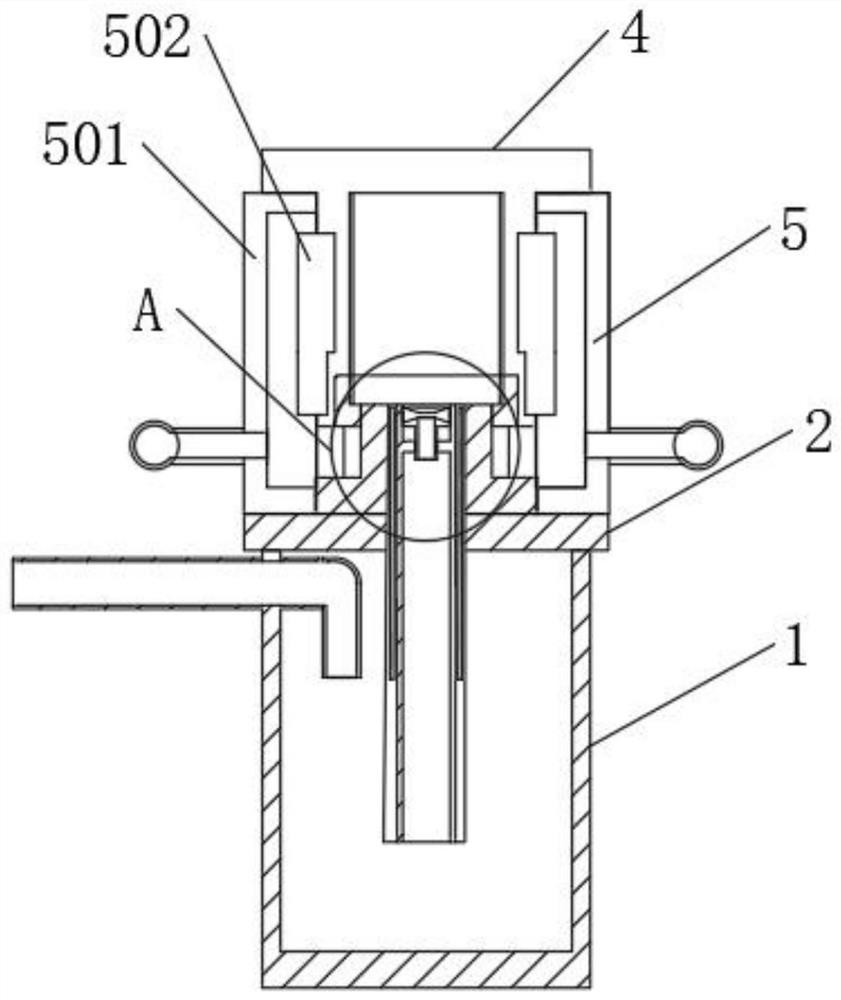

[0047] see Figure 1-3 , a high-strength low-pressure casting process for aluminum alloy castings for automobiles, comprising a low-pressure casting device, the low-pressure casting device includes a crucible 1, a pressure tube is fixedly connected to the crucible 1, and a demister is fixedly connected to the outlet end of the pressure tube The crucible 1 is fixedly connected with a sealing cover 2, the sealing cover 2 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com