Power van carriage modular production process and sealing testing method of carriage

A production process and modular technology, which is applied in the field of special vehicles, can solve the problems of easy noise leakage of generator sets, easy deformation of welding, and reduced carrying capacity of the whole vehicle, so as to reduce labor intensity, reduce the weight of carriages, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

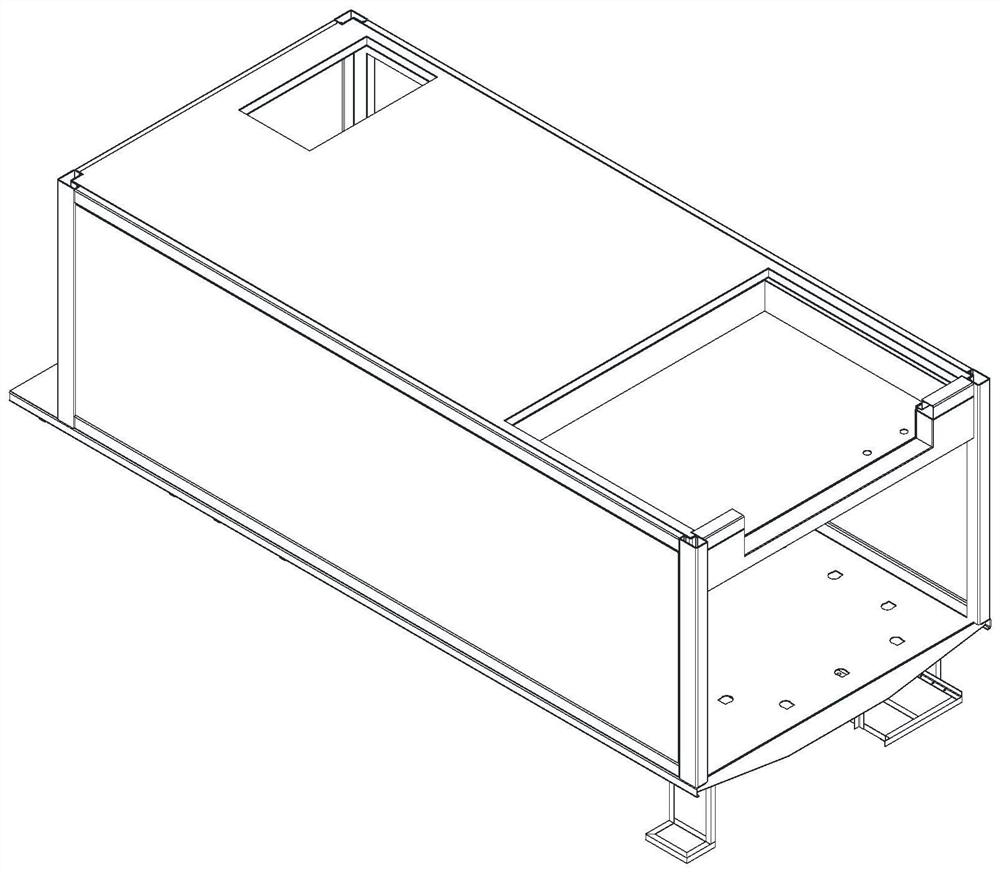

[0029] Figure 1~10 It is a preferred solution of the present invention, and the overall figure of the compartment is as follows figure 1 As shown, it is formed by splicing a plurality of compartment wall panels 1 .

[0030] The specific production process includes:

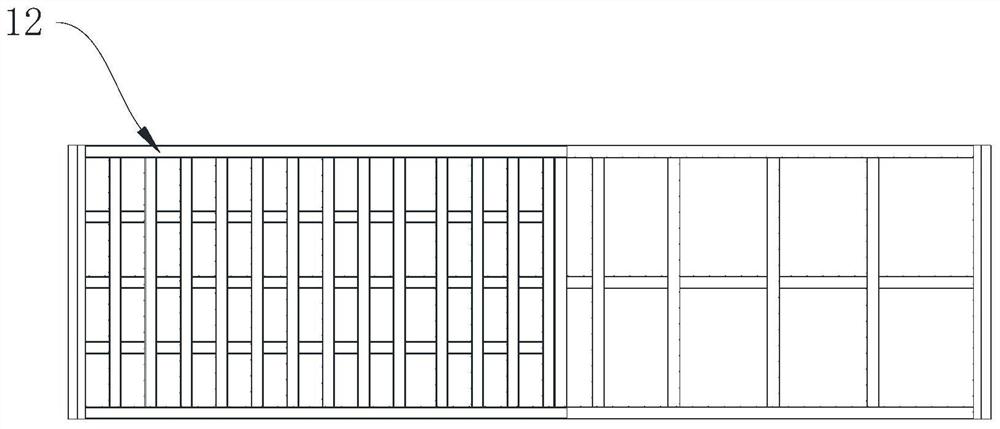

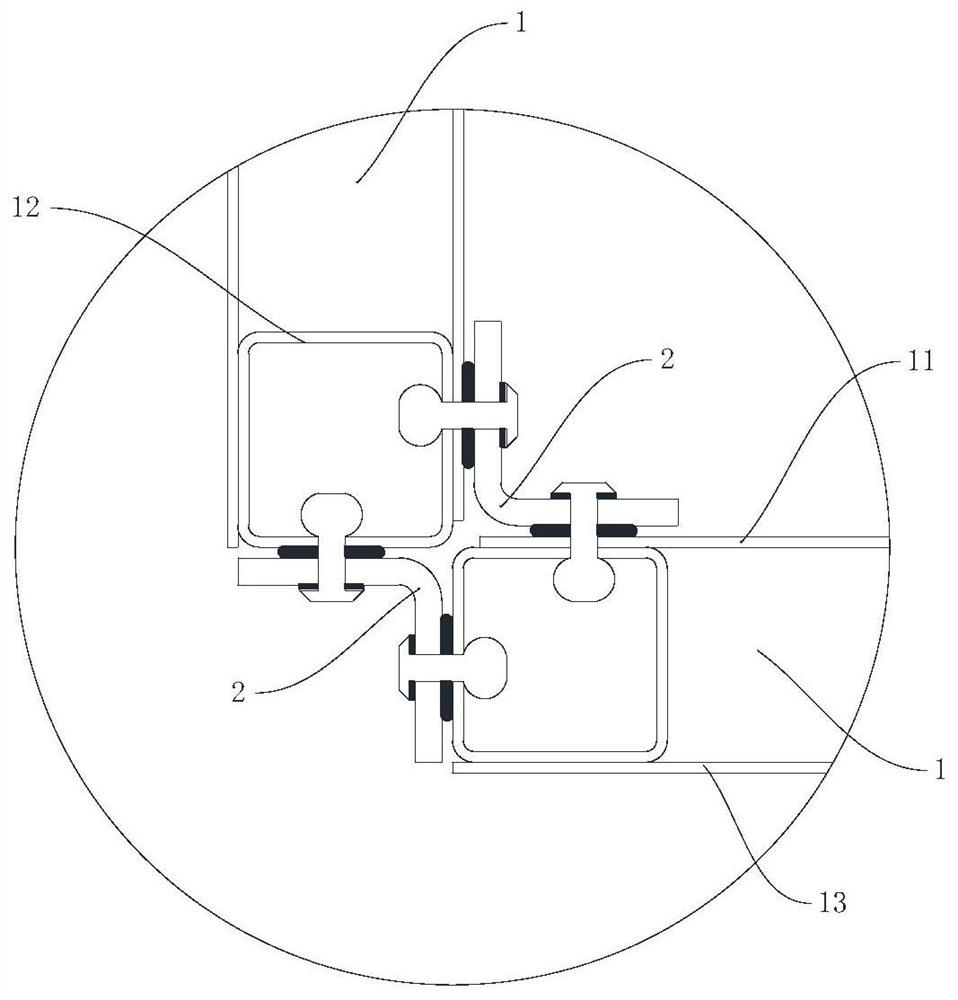

[0031] 1. The production of the compartment wall panel: the compartment panel 1 is composed of an inner panel 11, a skeleton 12 and an outer panel 13, and the skeleton 12 is a planar frame formed by welding multiple channel steels or splicing multiple aluminum profiles (such as figure 2 shown), the length and placement of channel steel or aluminum profiles are designed according to the structure and stress points of the carriage (such as the position of doors and windows, the position of partitions, etc.). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com