Film blowing machine for heat shrink film production

A heat-shrinkable film and film blowing machine technology, applied in the field of film blowing machines, can solve the problems of poor uniformity, low heating efficiency, and high maintenance costs, and achieve the effects of improving efficiency, low maintenance costs, and prolonging the movement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

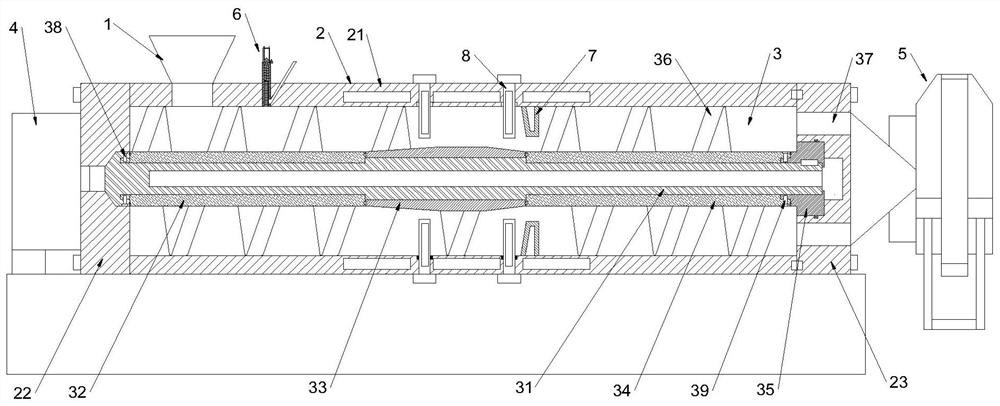

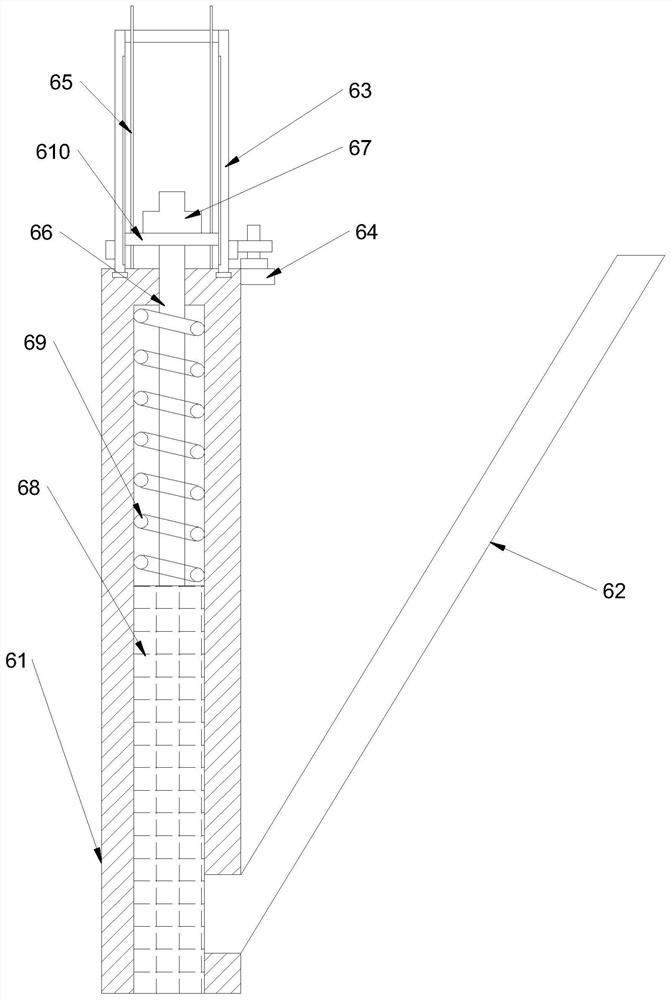

[0028] combine Figure 1 to Figure 2 The shown blown film machine for heat shrinkable film production, in this embodiment, includes an extrusion mechanism, the extrusion mechanism includes a feed hopper 1, an extrusion barrel 2, a screw assembly 3, a drive motor 4 and a die head 5 , a feed hopper 1 is provided above one end of the extrusion cylinder 2, a die head 5 is provided at the other end, a screw assembly 3 is arranged in the extrusion cylinder 2, and one end thereof is driven and connected with a driving motor 4, and the extrusion cylinder 2 includes a cylinder body 21 and the first end cover 22 and the second end cover 23 that are connected to the two ends of the cylinder body 21 by sealing; Tight sleeve 35; one end of the central rotating shaft 31 is rotatably connected in the first end cover 22, and is connected to the drive motor 4 connected outside the end cover. The first material delivery sleeve 32, the melting reinforcement sleeve 33, the second material delive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com