Automatic paper tube manufacturing device

A paper tube, automatic technology, applied in the engineering field, can solve problems such as single function and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

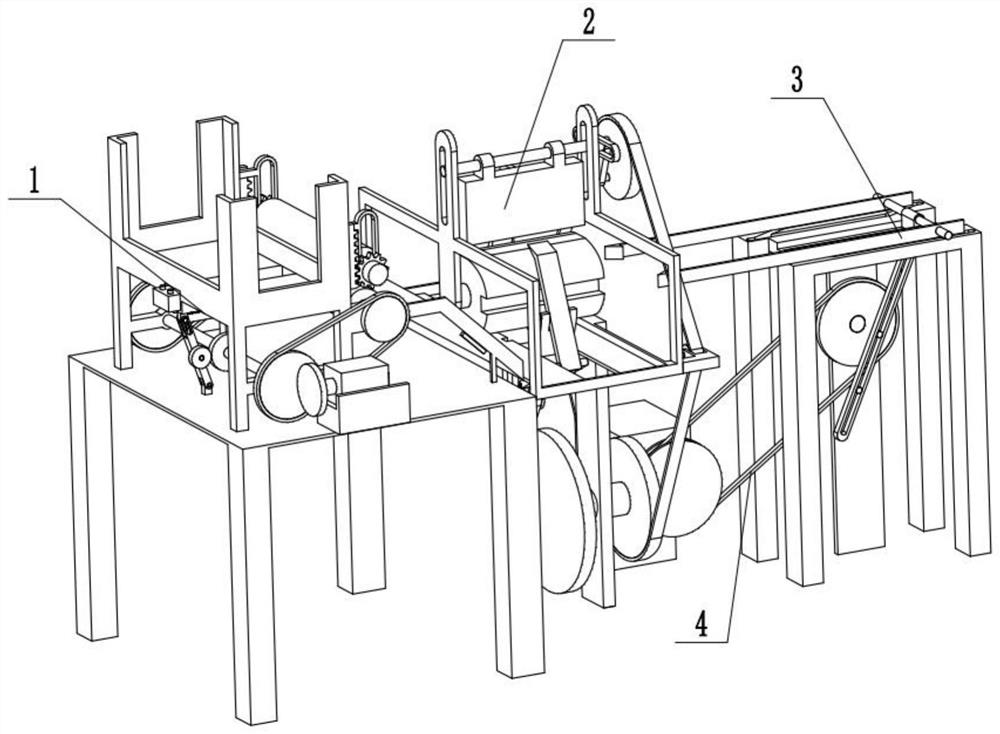

[0026] Combine below Figure 1-10 Description of the present embodiment, an automatic paper tube production device, including a paper separation device 1, a folding paper tube device 2, a peeling paper tube device 3, and a belt 4, the paper separation device 1 is connected with the folding paper tube device 2, Folding paper tube device 2 is connected with belt one 4, and peeling paper tube device 3 is connected with belt one 4.

specific Embodiment approach 2

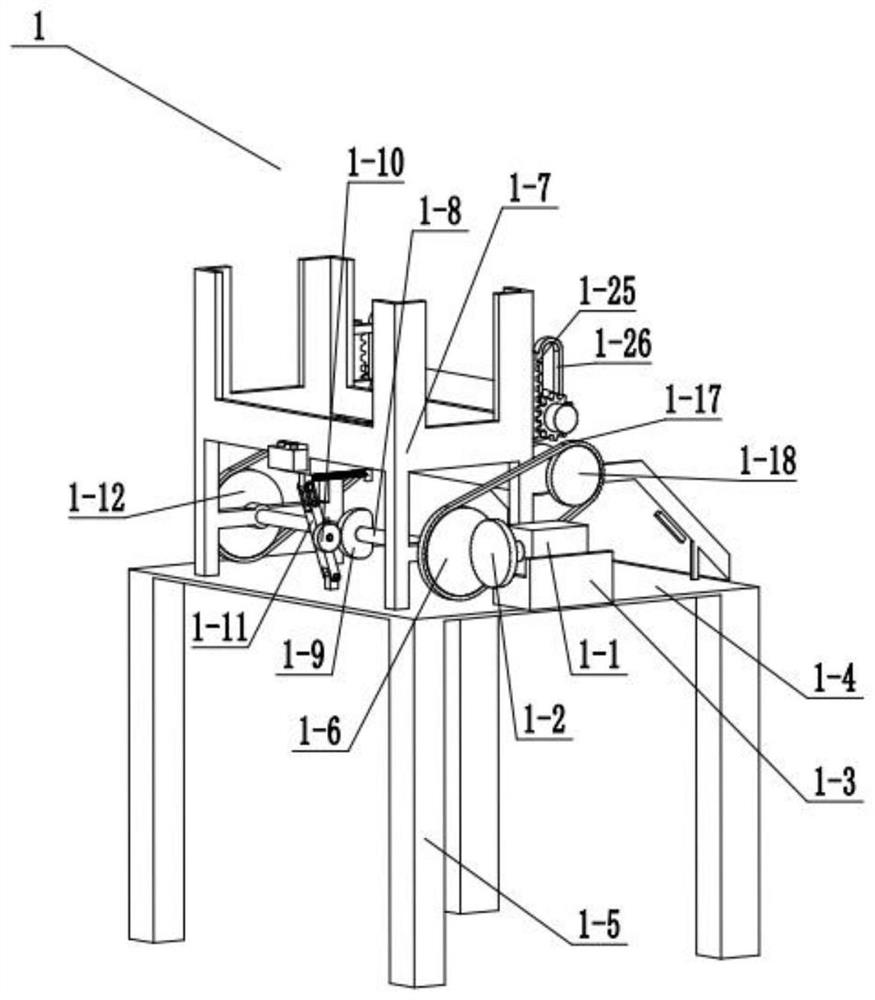

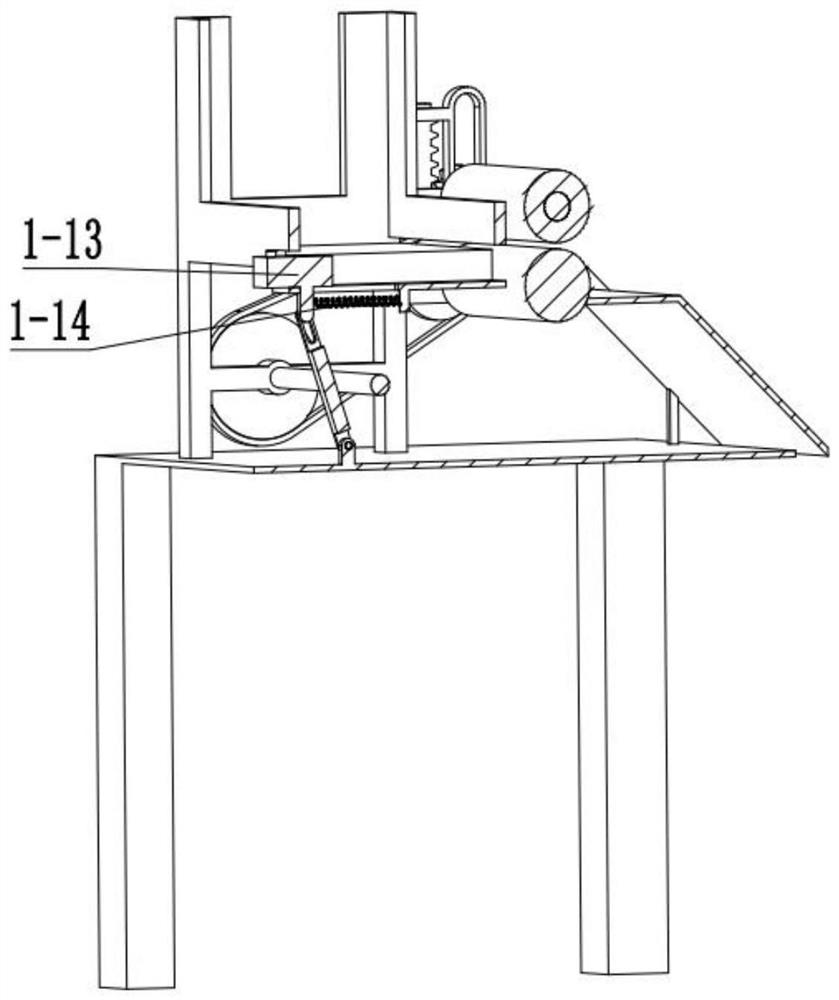

[0028] Combine below Figure 1-10Describe this embodiment, this embodiment will further explain Embodiment 1, the described paper separation device 1 includes a motor 1-1, a runner 1-2, a motor base 1-3, a base 1-4, and a tripod 1-5, runner two 1-6, upper frame 1-7, connecting column one 1-8, half runner 1-9, runner three 1-10, connecting rod one 1-11, runner four 1- 12. Slider 1-13, spring one 1-14, small cylinder 1-15, spring two 1-16, belt two 1-17, runner five 1-18, belt three 1-19, runner six 1- 20. Roller one 1-21, roller two 1-22, knob 1-23, gear one 1-24, straight tooth one 1-25, straight groove one 1-26, slideway 1-27, rubber brush 1- 28. Motor one 1-1 is fixedly connected with runner one 1-2, motor one 1-1 is slidingly connected with motor base 1-3, motor base 1-3 is fixedly connected with base 1-4, four tripods 1- 5 are all fixedly connected with the base 1-4, the first runner 1-2 is connected with the second runner 1-6, the base 1-4 is fixedly connected with the ...

specific Embodiment approach 3

[0031] Combine below Figure 1-10 Describe this embodiment, this embodiment will further explain the first embodiment, the origami tube device 2 includes motor two 2-1, runner seven 2-2, runner eight 2-3, connecting column five 2-4, Bracket three 2-5, belt five 2-6, runner nine 2-7, small cylinder two 2-8, connecting rod two 2-9, connecting block 2-10, straight groove two 2-11, connecting rod three 2 -12, connecting rod four 2-13, connecting rod five 2-14, small cylinder three 2-15, bracket two 2-16, paper tube mold 2-17, connecting column six 2-18, groove 2-19, Pulley two 2-20, small cylinder four 2-21, runner ten 2-22, small cylinder five 2-23, connecting rod six 2-24, straight groove five 2-25, straight groove six 2-26, small cylinder Ten 2-27, connecting column ten 2-28, gravity block 2-29, motor two 2-1 is fixedly connected with runner seven 2-2, and runner seven 2-2 cooperates with runner eight 2-3 to connect, turn Wheel eight 2-3 is fixedly connected with connecting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com