Automatic three-dimensional warehouse storage device for large and medium-sized stamping dies

A stamping die and storage device technology, which is applied in the field of large and medium-sized stamping die automatic three-dimensional warehouse storage device, can solve the problems of wasting time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

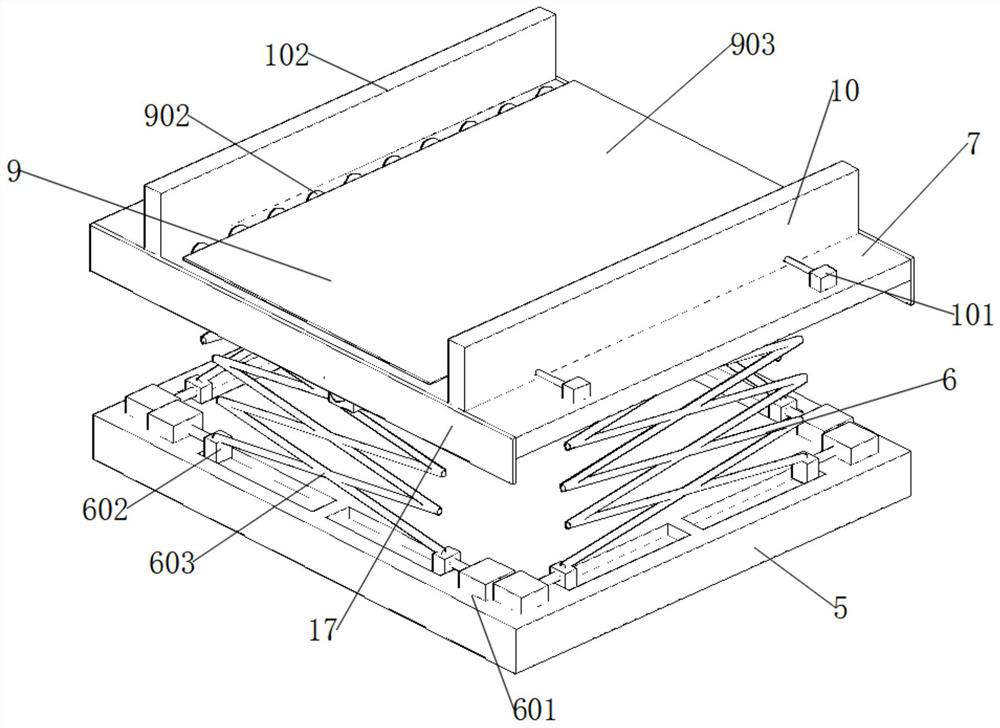

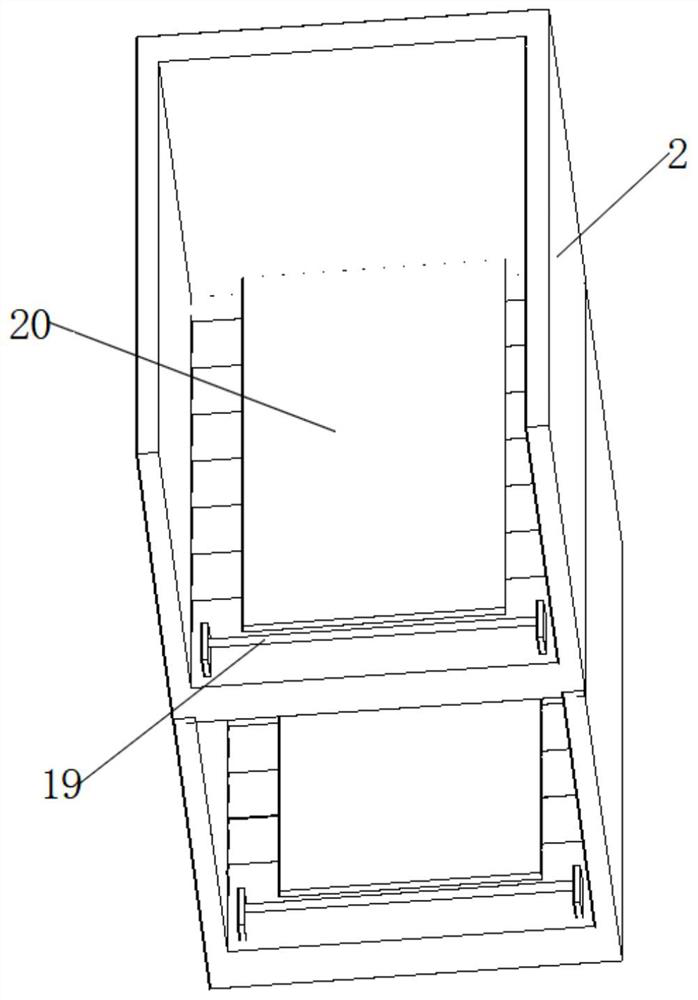

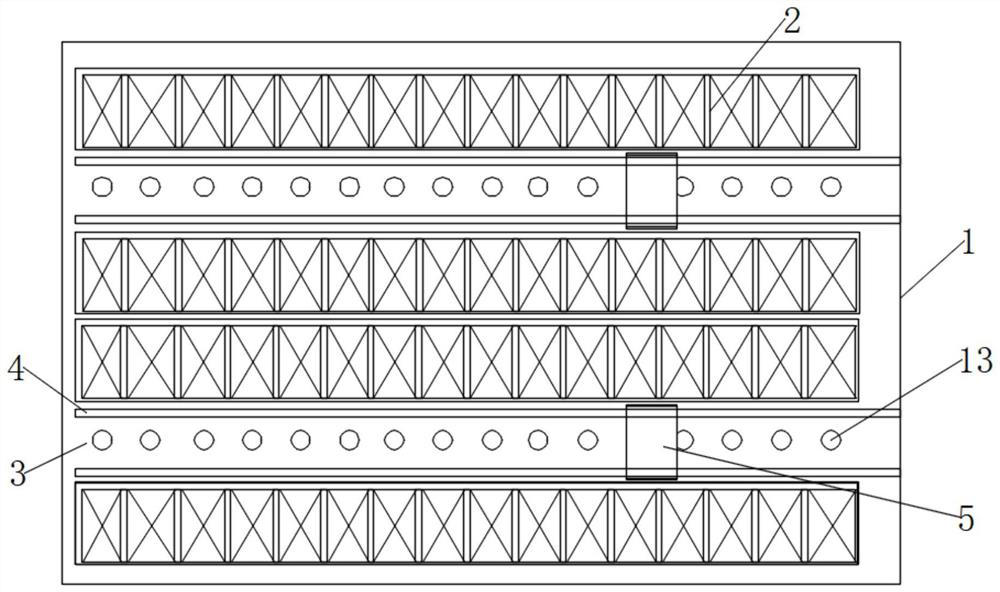

[0041] Such as Figure 1-7 As shown, the embodiment of the present invention provides an automatic three-dimensional library storage device for large and medium-sized stamping dies, including a storage bin 1 and an operation room 8, the storage bin 1 is used to store molds, and the operation room 8 is used to observe the situation inside the storage bin 1 At the same time, the movement error is corrected. The interior of the storage bin 1 is provided with a storage rack 2 for placing the mould. The interior of the storage rack 2 is provided with a storage cavity. Out of the storage rack 2, the structure of the transmission mechanism 20 is the same as that of the push-pull mechanism 9. There are multiple storage racks 2. The storage rack 2 is divided into a large mold rack and a medium mold rack. The large mold rack has five layers, and the medium mold rack has six layers. Layers, with different heights, are used to store molds of different sizes, and a lane 3 is set between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com