Chemical silvering device for plastic products

A technology of chemical silver plating and plastic products, applied in liquid chemical plating, metal material coating technology, coating, etc., can solve the complicated and complicated silver plating process, hidden dangers to the health and safety of staff, and easy adhesion of chemical silver plating Raw material solution and other issues, to improve the effect of immersion silver plating, ensure personal health, and improve the efficiency of silver plating processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

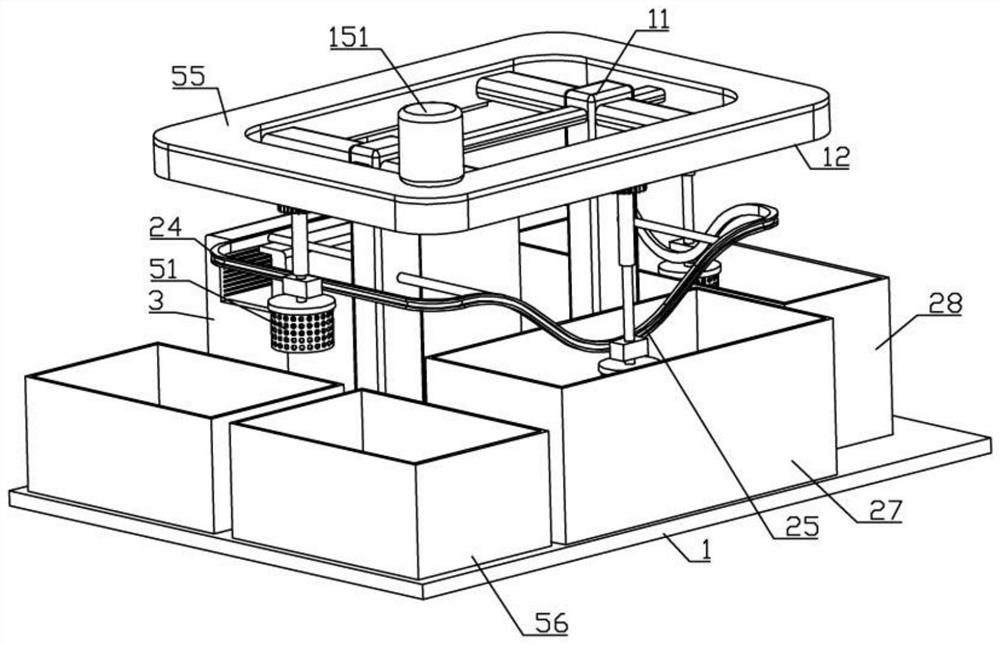

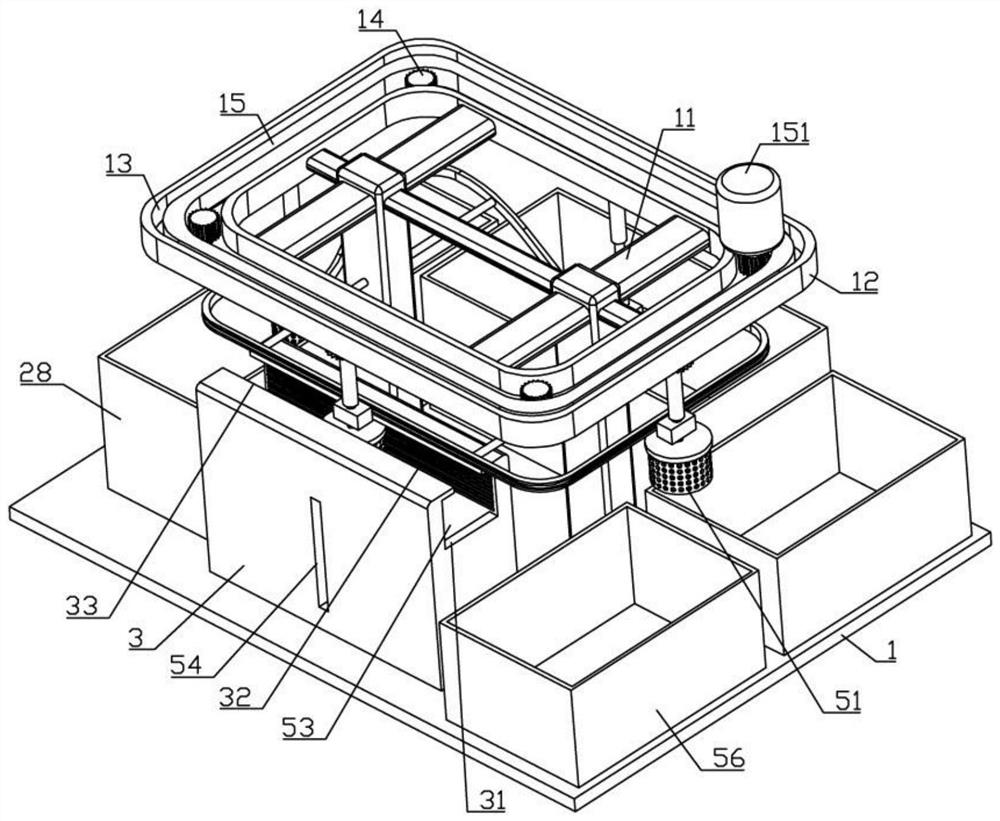

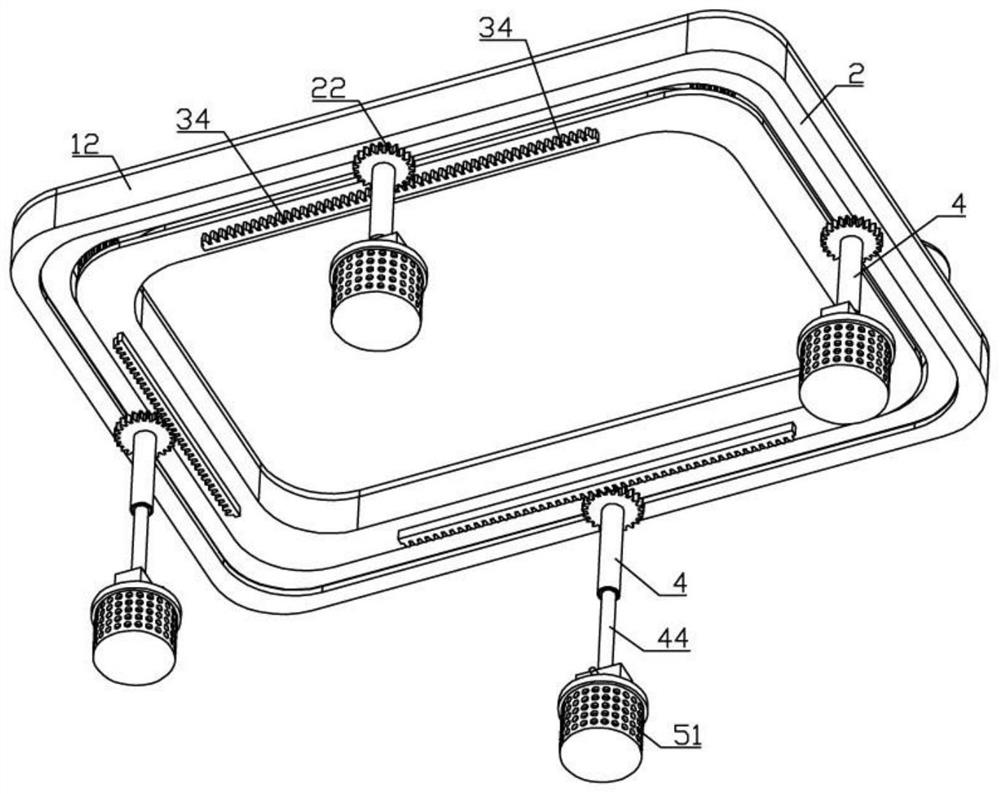

[0028] like Figure 1~5 As shown, the present invention is a chemical silver plating device for plastic products, comprising a base 1, a support 11 is provided at the center of the upper end surface of the base 1, a mounting frame 12 is provided at the upper end of the support 11, and a mounting frame 12 is provided at the upper end of the mounting frame 12. Surrounding the through groove 13 of the bracket 11, a plurality of first gears 14 are installed at intervals in the through groove 13, and a transmission chain 15 is set on a plurality of the first gears 14, and a cover plate is installed on the through groove 13 55, a motor 151 is installed on the cover plate 55, the drive shaft of the motor 151 is in transmission connection with one of the first gears 14, and the lower end of the mounting frame 12 is provided with a slide that passes through the through groove 13. Slot 2, the lower side of the transmission chain 15 is fixedly provided with several vertical connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com