Anti-adhesion and fracture acetate pulp silk equipment and technology

An anti-adhesion and acetic acid technology, applied in the field of textiles, can solve the problems of wire adhesion and breakage, and achieve the effects of synchronizing the action, reducing the cost of use, and improving the uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

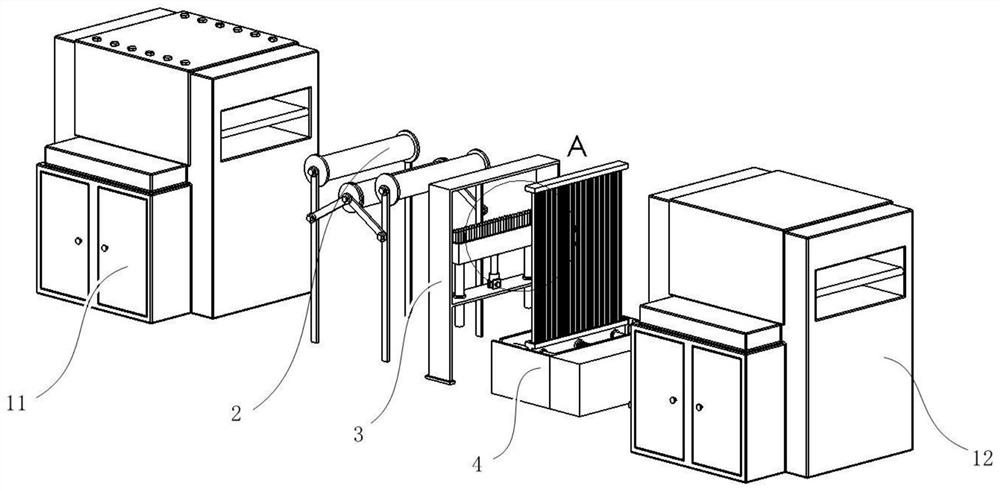

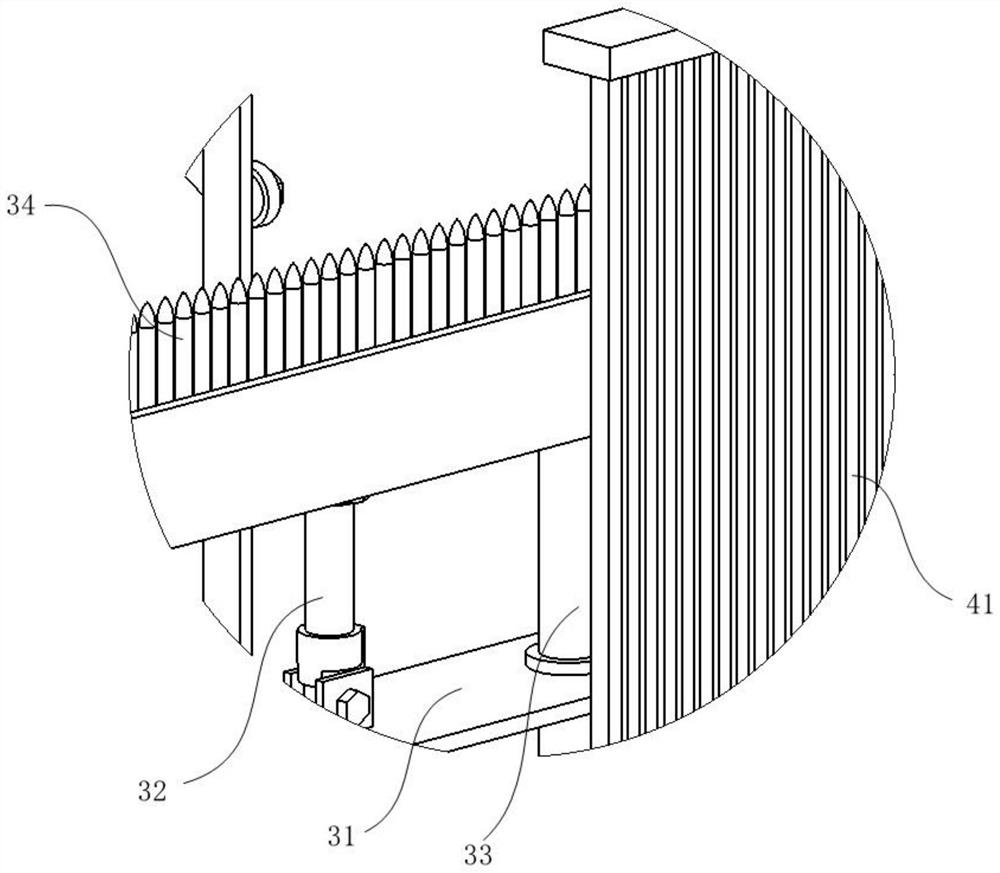

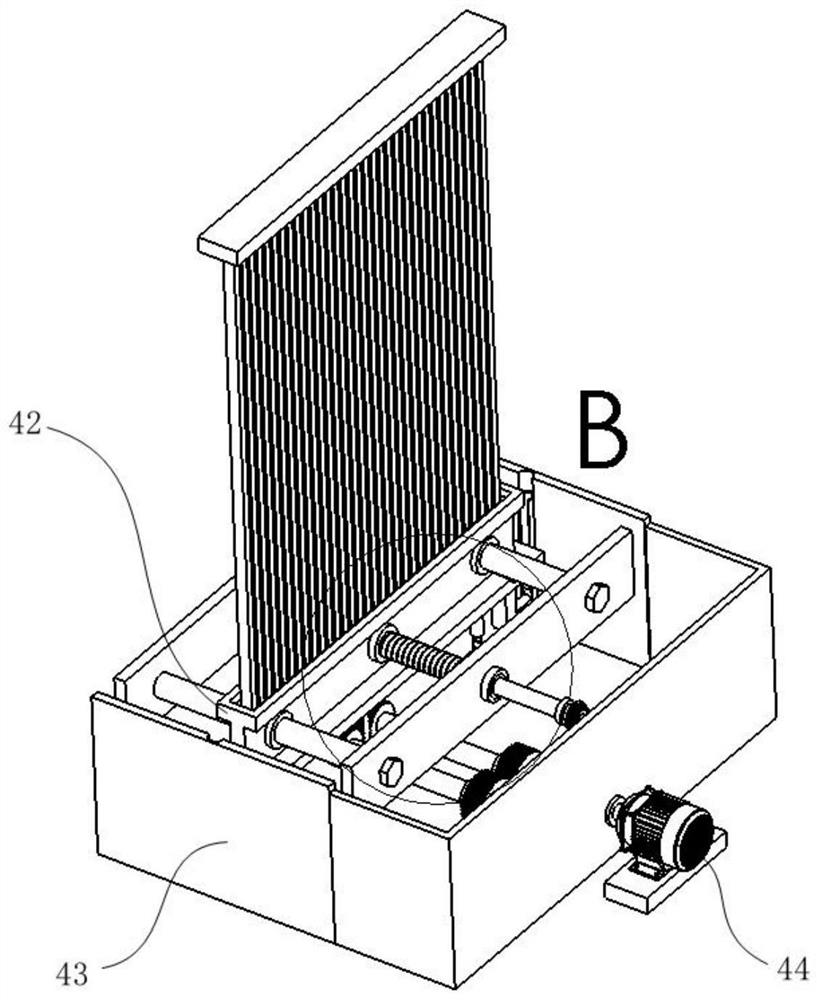

[0038] like figure 1As shown, a kind of anti-blocking and fracture acetate pulp silk equipment comprises the first oven 11 and the second oven 12 which are arranged in sequence for baking the silk thread after sizing, and the first oven 11 and the second oven 12 The tensioning mechanism 2 for tensioning the yarn, the dividing mechanism 3 for separating the thread, and the swinging reed mechanism 4 for passing the separated thread are arranged in sequence in the middle. The reed tooth 41 of the swinging reed mechanism 4 Only a single thread can pass through the space, and the bottom end is provided with a driving assembly for driving the reed tooth 41 to move. The driving assembly includes a lifting mechanism for driving the reed tooth 41 to move up and down and a traverse mechanism for driving the reed tooth 41 to move forward and backward. Through the up and down movement and forward and backward movement of the swinging reed mechanism 4, the reed teeth 41 act on the silk thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com