Continuous small box girder structure with combined section in hogging moment area and construction method thereof

A technology of negative bending moment area and small box girder, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large shrinkage of UHPC and cannot maximize the cracking moment of the section, so as to improve the cracking moment , enhance environmental erosion resistance, and improve durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

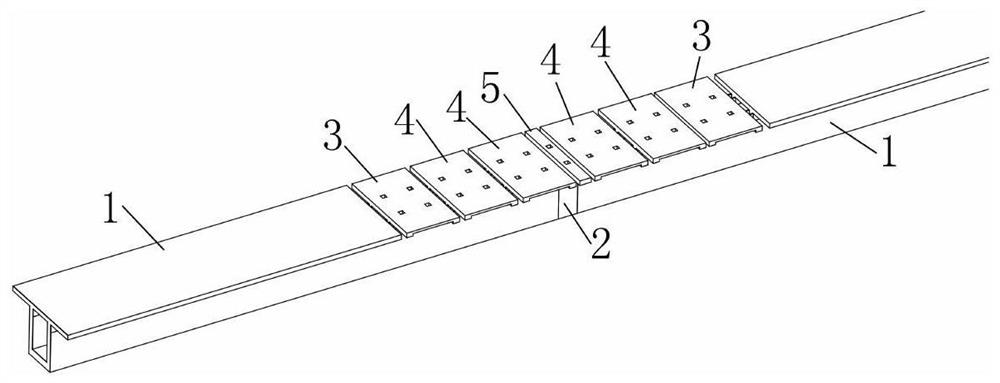

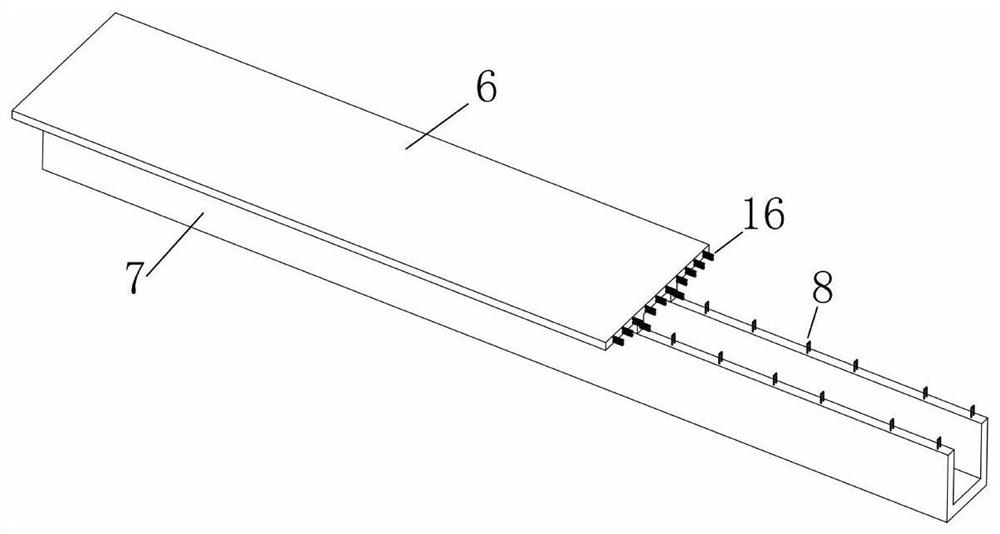

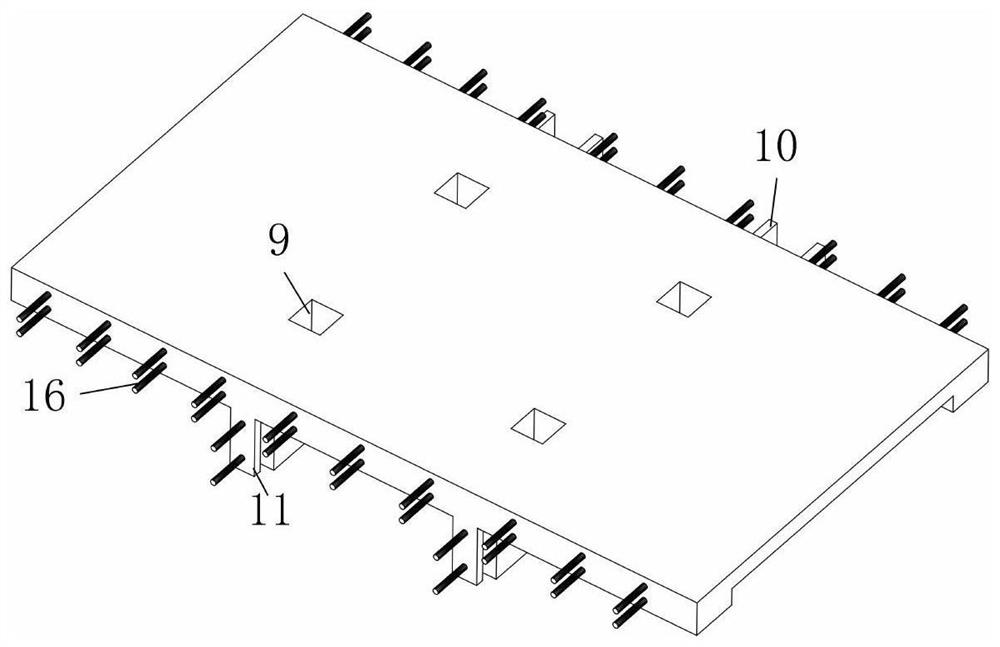

[0040] Such as Figure 1-6 As shown, this embodiment provides a continuous small box girder structure with combined sections in the negative moment zone, including prefabricated NC small box girder 1, mid-support cast-in-place NC 2, A-type prefabricated UHPC channel plate 3, and B-type prefabricated UHPC channel plate 4, C-type prefabricated UHPC channel plate 5. The adjacent prefabricated NC small box girder 1 is connected as a whole through the middle fulcrum cast-in-place NC 2, and the NC channel beam 7 is connected with A-type prefabricated UHPC channel plate 3, B-type prefabricated UHPC channel plate 4, and C-type prefabricated UHPC channel plate 5 are connected together through the steel connectors 8 laid on the NC channel beam 7 . Type A prefabricated UHPC channel plate 3 and NC plate 6 are provided with steel bars 16 at the joint, Type A prefabricated UHPC channel plate 3 and B type prefabricated UHPC channel plate 4, and Type B prefabricated UHPC channel plate 4 Joi...

Embodiment 2

[0051] Such as Figure 7 As shown, this embodiment provides a continuous small box girder structure with a combined section in the negative moment area. The difference from the embodiment is that in this embodiment, the negative moment prefabricated section is replaced by a D-shaped prefabricated UHPC channel plate 17 A multi-section prefabricated panel composed of type A prefabricated UHPC channel plate 3 and type B prefabricated UHPC channel plate 4, such as Figure 8 shown. The combined cross-sectional form of the central fulcrum connecting section composed of the central fulcrum cast-in-place NC2 and the C-shaped prefabricated UHPC channel plate 5 becomes the cast-in-place UHPC connecting section 18 .

[0052] The construction method of the continuous small box girder structure with combined section in the negative moment zone includes the following steps:

[0053] 1) Prefabricated NC small box girder 1 and D-shaped prefabricated UHPC channel plate 17 are produced in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com