Formula for improving cracking bending moment of concrete pipe pile and preparation method thereof

A concrete pipe pile and formula technology, which is applied in the field of pipe pile manufacturing, can solve the problems of not being able to adapt to places with high requirements for pipe pile crack resistance and bending moment, reduce pipe pile production efficiency, increase pipe pile manufacturing cost, etc., and reduce energy consumption. wear, improve cracking moment, and ensure the effect of forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

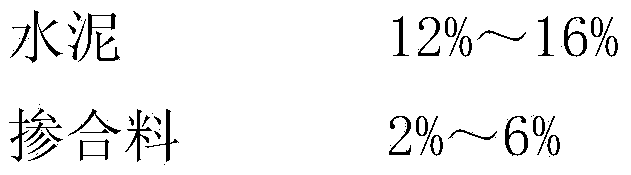

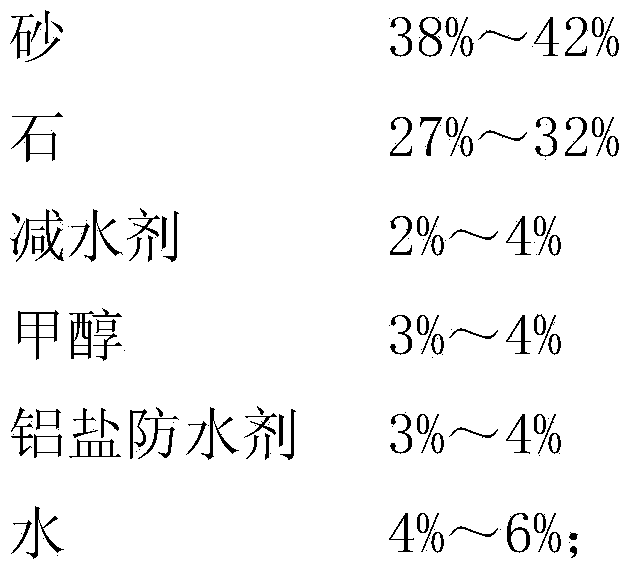

[0027] A formula for improving the anti-cracking moment of concrete pipe piles. The formula includes cement, admixtures, sand, stone, water reducing agent, methanol, aluminum salt waterproofing agent and water. The mass percentage of each component is as follows:

[0028]

[0029]

[0030] The admixture is a mixture of fly ash, carbonaceous rock powder and ground quartz sand, and the fly ash, carbonaceous rock powder and ground quartz sand are prepared in a ratio of 1.5:1.5:1.

[0031] A preparation method for improving the anti-cracking moment formula of concrete pipe piles, the preparation method comprising the following steps:

[0032] 1) Mix cement, sand and stone in a certain proportion to form a preliminary mixture;

[0033] 2) The PH value of the water is adjusted to 7~9, and the water temperature is controlled at 20°C~30°C;

[0034] 3) Mix the aluminum salt water repellent with water evenly;

[0035] 4) Mix the mixture of aluminum salt waterproofing agent and w...

Embodiment 2

[0048] A formula for improving the anti-cracking moment of concrete pipe piles. The formula includes cement, admixtures, sand, stone, water reducing agent, methanol, aluminum salt waterproofing agent and water. The mass percentage of each component is as follows:

[0049]

[0050] The admixture is a mixture of fly ash, carbonaceous rock powder and ground quartz sand, and the fly ash, carbonaceous rock powder and ground quartz sand are prepared in a ratio of 1.5:1.5:1.

[0051] A preparation method for improving the anti-cracking moment formula of concrete pipe piles, the preparation method comprising the following steps:

[0052] 1) Mix cement, sand and stone in a certain proportion to form a preliminary mixture;

[0053] 2) The PH value of the water is adjusted to 7~9, and the water temperature is controlled at 20°C~30°C;

[0054] 3) Mix the aluminum salt water repellent with water evenly;

[0055] 4) Mix the mixture of aluminum salt waterproofing agent and water into th...

Embodiment 3

[0068] A formula for improving the anti-cracking moment of concrete pipe piles. The formula includes cement, admixture, sand, stone, water reducing agent, methanol, aluminum salt waterproofing agent and water. The mass percentage of each component is as follows:

[0069]

[0070] The admixture is a mixture of fly ash, carbonaceous rock powder and ground quartz sand, and the fly ash, carbonaceous rock powder and ground quartz sand are prepared in a ratio of 1.5:1.5:1.

[0071] A preparation method for improving the anti-cracking moment formula of concrete pipe piles, the preparation method comprising the following steps:

[0072] 1) Mix cement, sand and stone in a certain proportion to form a preliminary mixture;

[0073] 2) The PH value of the water is adjusted to 7~9, and the water temperature is controlled at 20°C~30°C;

[0074] 3) Mix the aluminum salt water repellent with water evenly;

[0075] 4) Mix the mixture of aluminum salt waterproofing agent and water into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com