Loader cab layout method based on ergonomics and cab

A technology of ergonomics and layout method, which is applied in earth mover/excavator, construction, sustainable transportation, etc. It can solve problems such as poor tolerance, excessive stroke design, and poor versatility of molding molds for manipulating parts, so as to reduce materials Waste, improve mold utilization, and simplify the effect of design steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

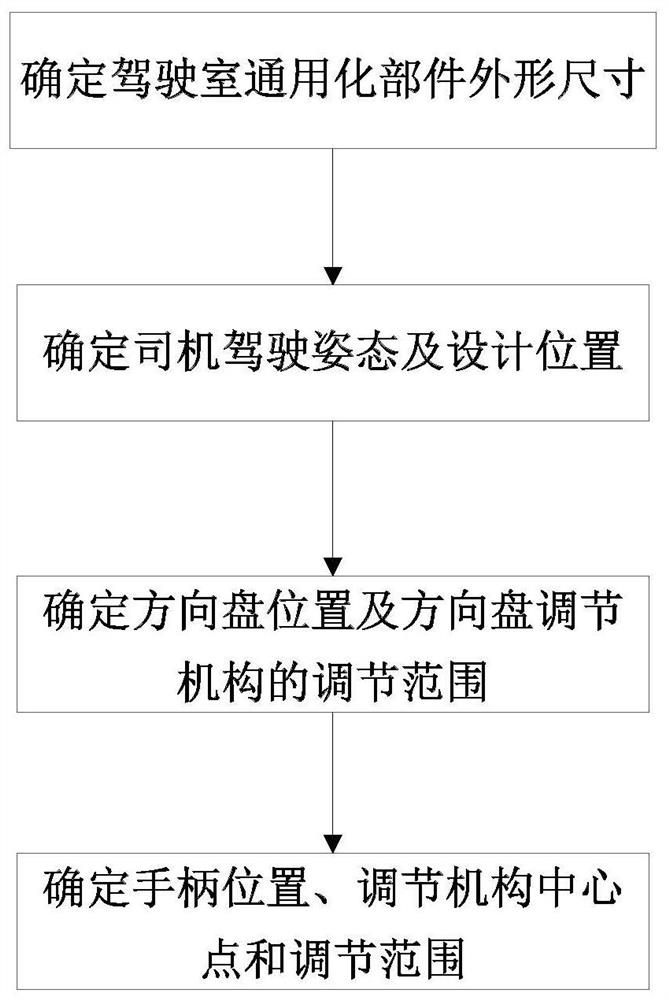

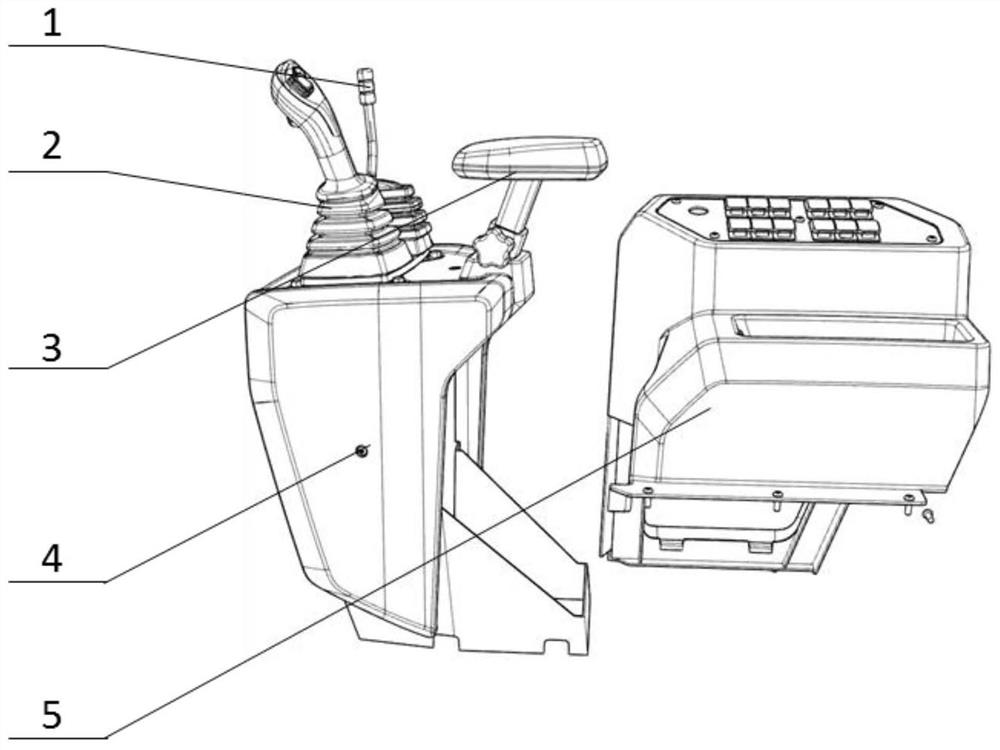

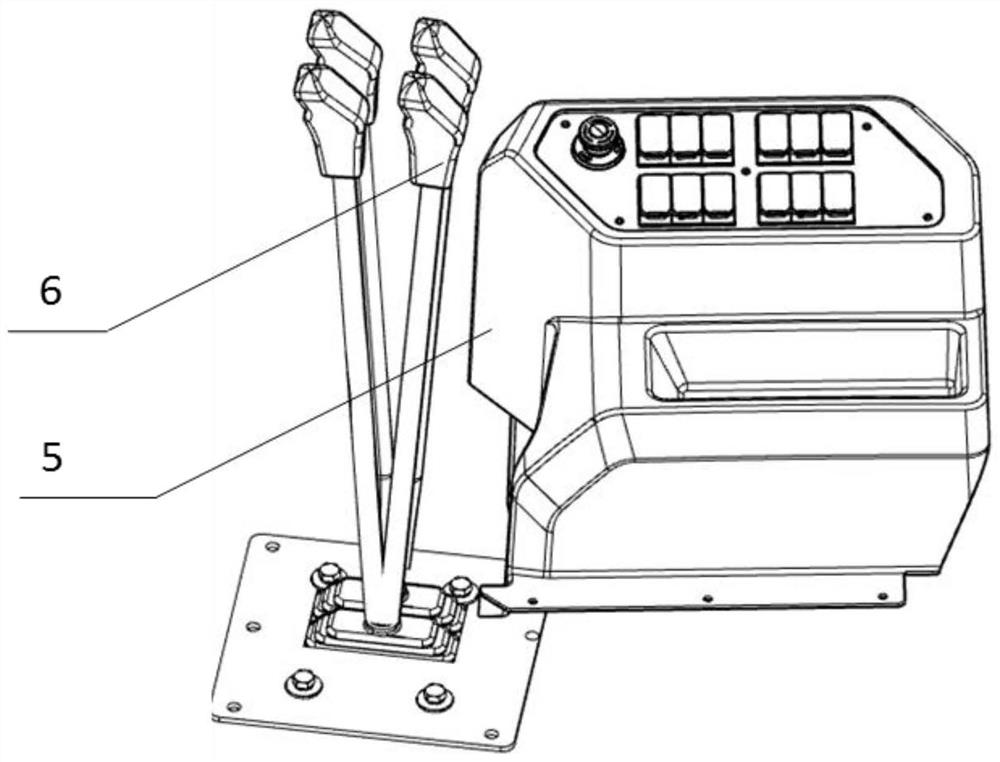

[0048] The invention as figure 1 The specific content shown includes four steps: determine the overall dimensions of the general components of the cab; determine the driver's driving posture and design position; determine the steering wheel position and the adjustment range of the steering wheel adjustment mechanism; determine the handle position, the center point of the handle adjustment mechanism and the adjustment scope.

[0049] (1) Determine the overall dimensions of the common parts of the cab.

[0050] In the early stage of cab design, the design size of generalized components is determined, which can accurately constrain the size of the cab, avoiding the phenomenon that the cab repeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com