Air bearing compressor

An air bearing and compressor technology, applied in the field of compressors, can solve the problems of air disturbance, rotor tilt, low work efficiency, etc., and achieve the effects of reducing manufacturing and practical costs, increasing gas pressure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

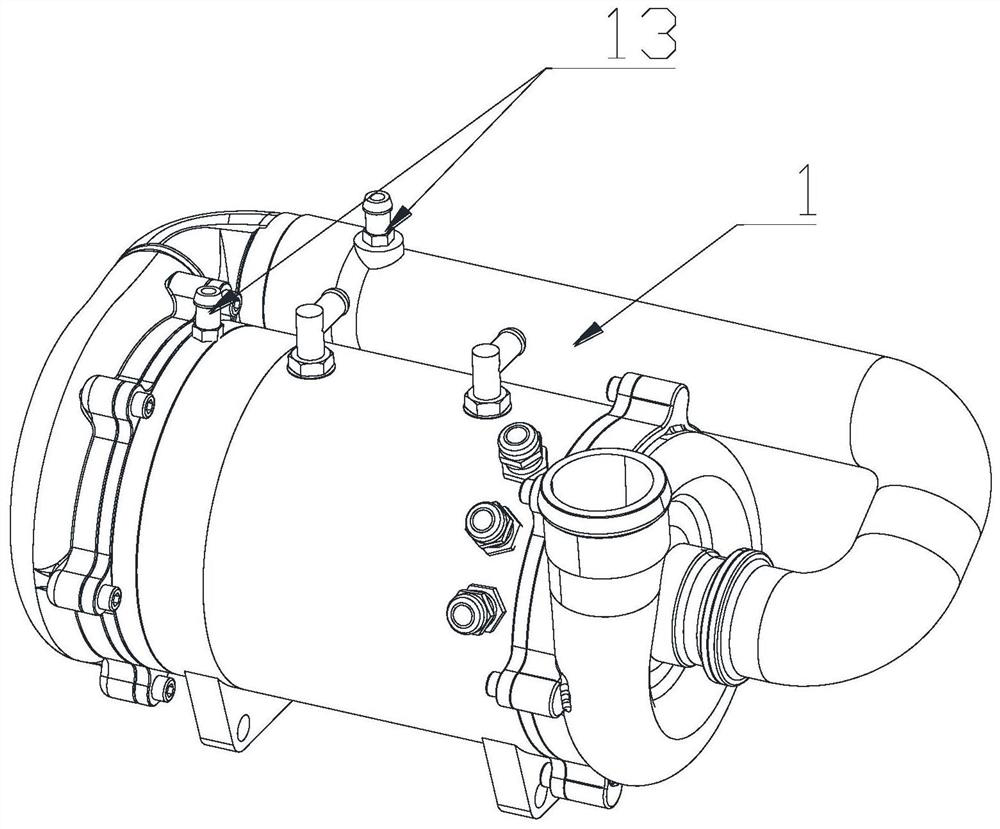

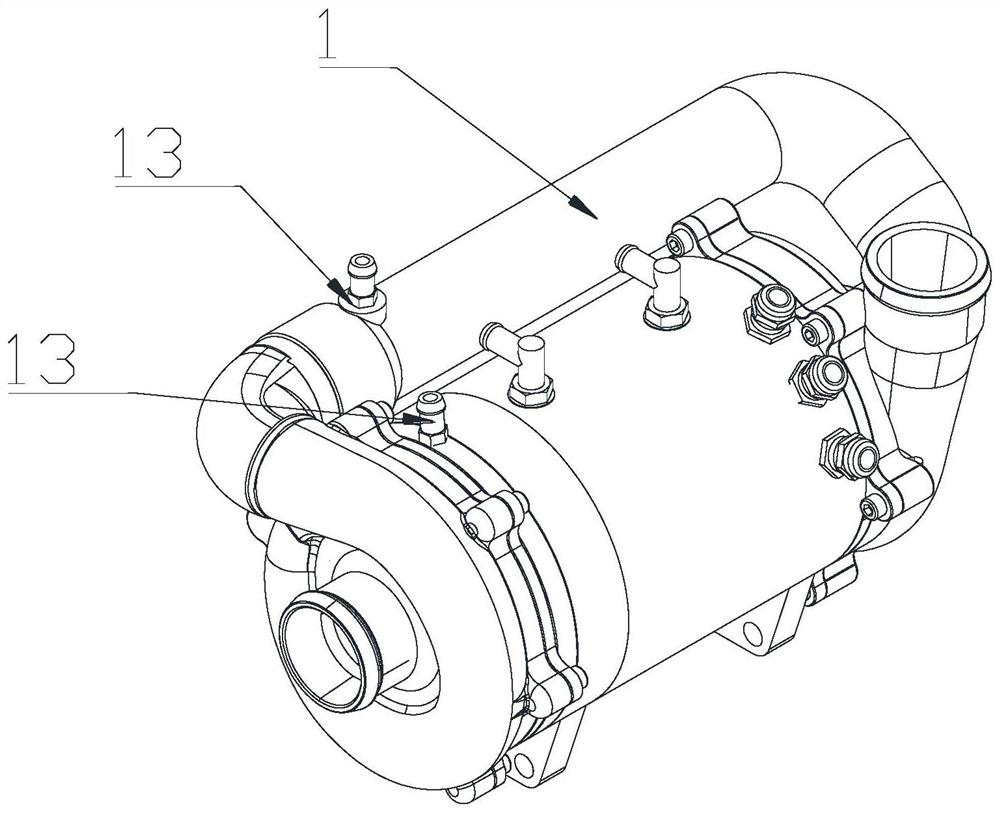

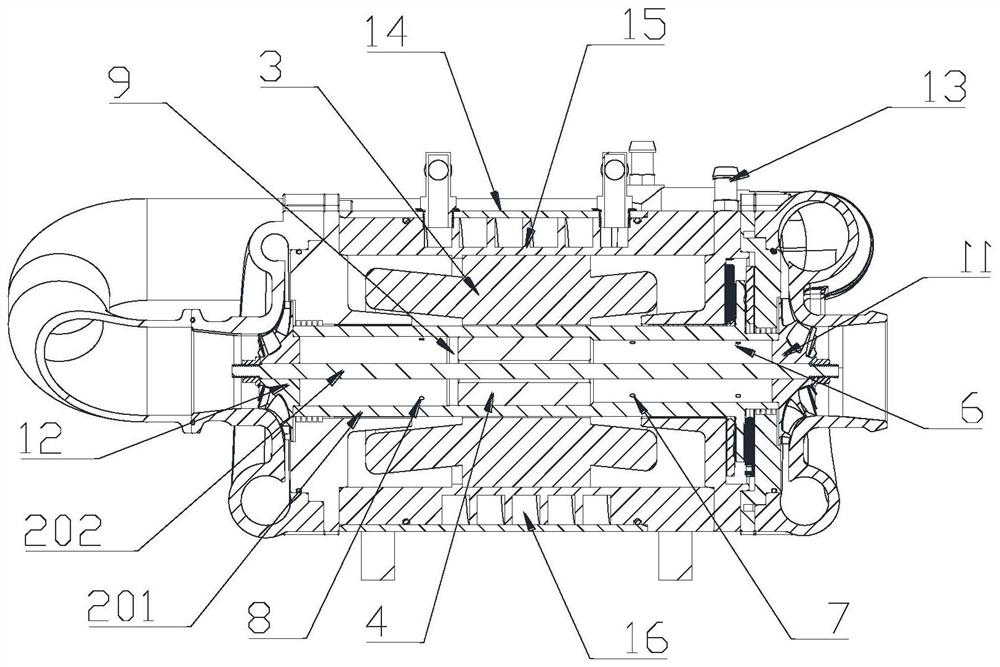

[0029] see Figure 1-Figure 4 , The air bearing compressor of the present invention includes a casing, a compression mechanism arranged in the casing, and a compression drive mechanism for driving the compression mechanism to work.

[0030] see Figure 1-Figure 4 , the compression mechanism includes a first compression member and a second compression member, wherein the first compression member and the second compression member are located on both sides of the housing; the housing is in contact with the first compression member A first compression cavity and a second compression cavity are respectively provided at corresponding positions of the second compression element, the first compression element is arranged in the first compression cavity; the second compression element is arranged in the second compression cavity; The gas outlet of the first compression chamber communicates with the gas inlet of the second compression chamber through a connecting pipe 1 .

[0031] see...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the first-stage impeller 11 or \and the second-stage impeller 12 are centrifugal compression impellers.

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1 is that a communication groove for connecting the first cavity and the second cavity is provided in the rotating sleeve 202 , and the communication groove forms the second gas channel 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com