Standard consistency safety monitoring system for cement building material production and monitoring method thereof

A standard consistency and safety monitoring technology, applied in the direction of measuring devices, analytical materials, viscometer maintenance, etc., can solve the problems of single monitoring method and inability to display the consistency intuitively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

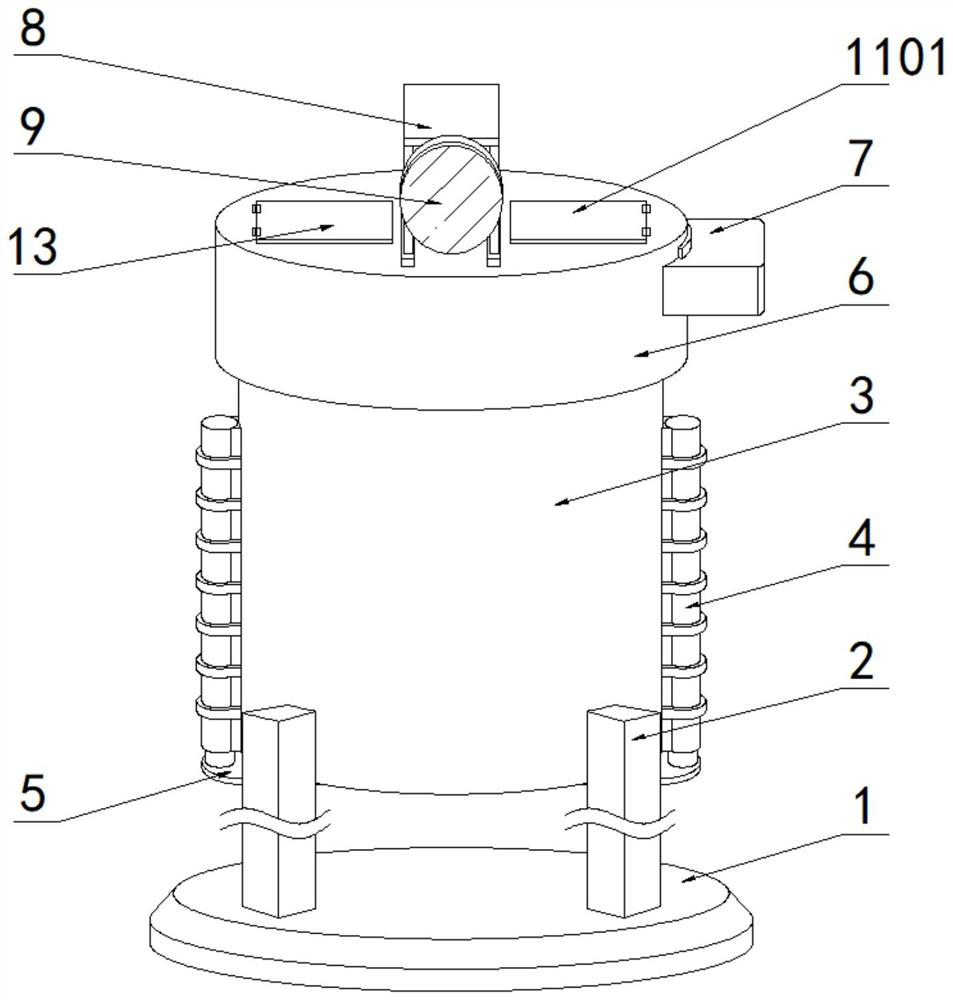

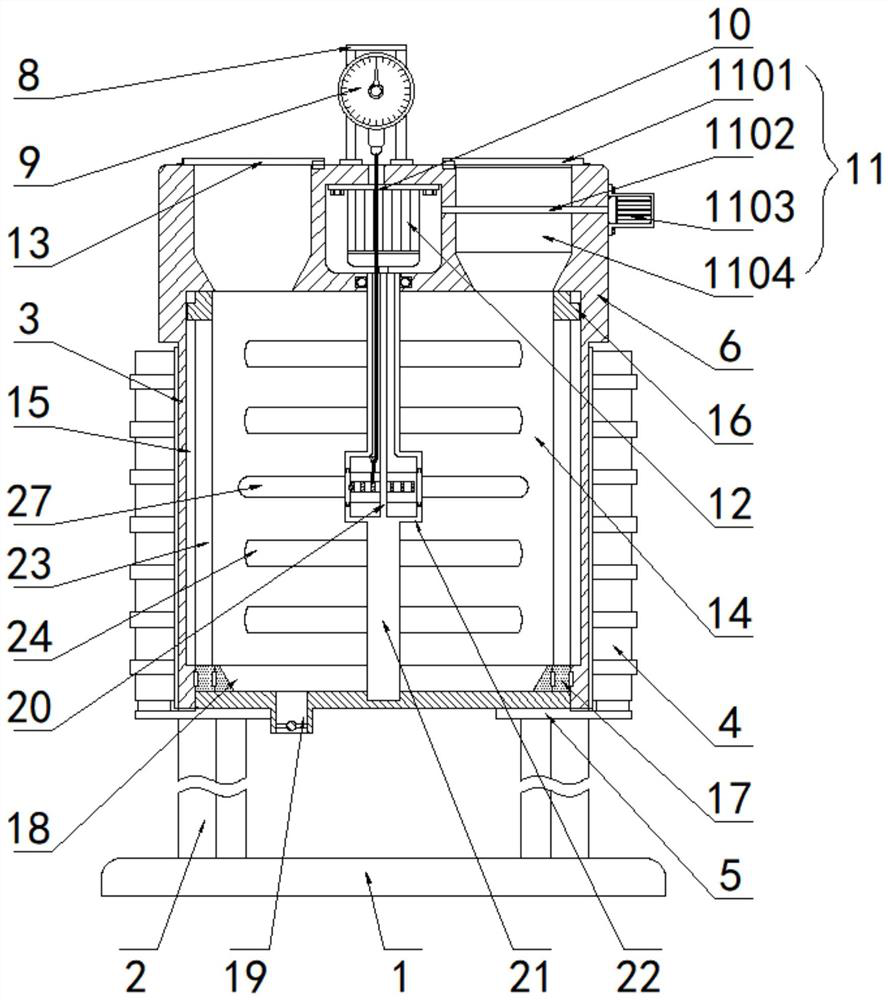

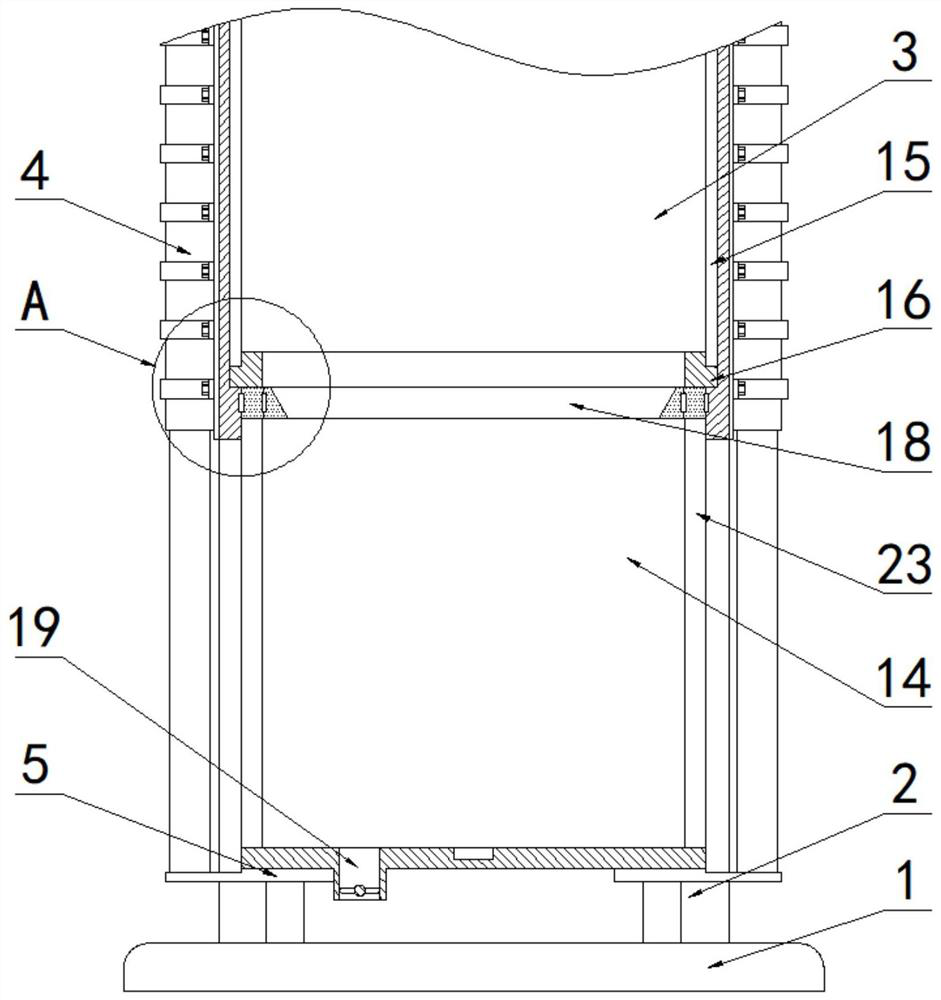

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0043] At present, some existing consistency monitoring and processing devices cannot monitor the standard consistency of cement intuitively during use, and it is difficult to perform real-time detection. At the same time, it is usually necessary to feed the cement after it is fully mixed, and then test it. The process of using the device is cumbersome, which is not conducive to efficient work;

[0044] Moreover, some existing cement standard consistency monitoring devices are inconvenient to adjust the position of the discharge during the discharge process. Usually, the discharge can only be carried out from a single position. The existing cement standard consistency monitoring cannot During the material process, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com