Composite melt for fuse and fuse

A fuse and melt technology, applied in electrical components, circuits, emergency protection devices, etc., can solve the problems of slow heat accumulation in the narrow diameter of the melt, unfavorable insulation performance, lap bonding and adhesion of fuse points, etc., and shorten the arc extinguishing time. , Conducive to arc extinguishing and rigidity enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

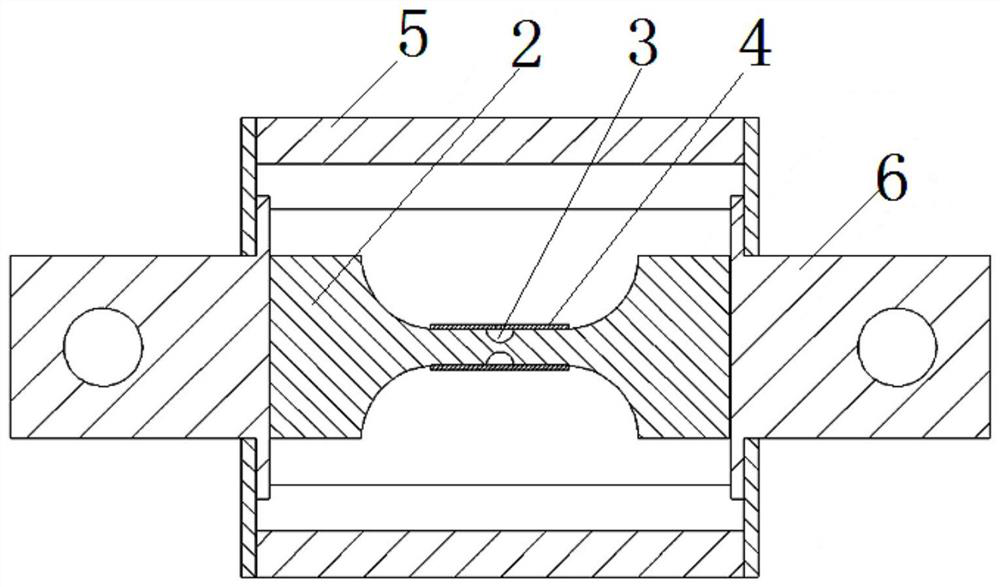

[0023] With regard to the above technical solutions, preferred embodiments are given and described in detail in conjunction with the drawings. in:

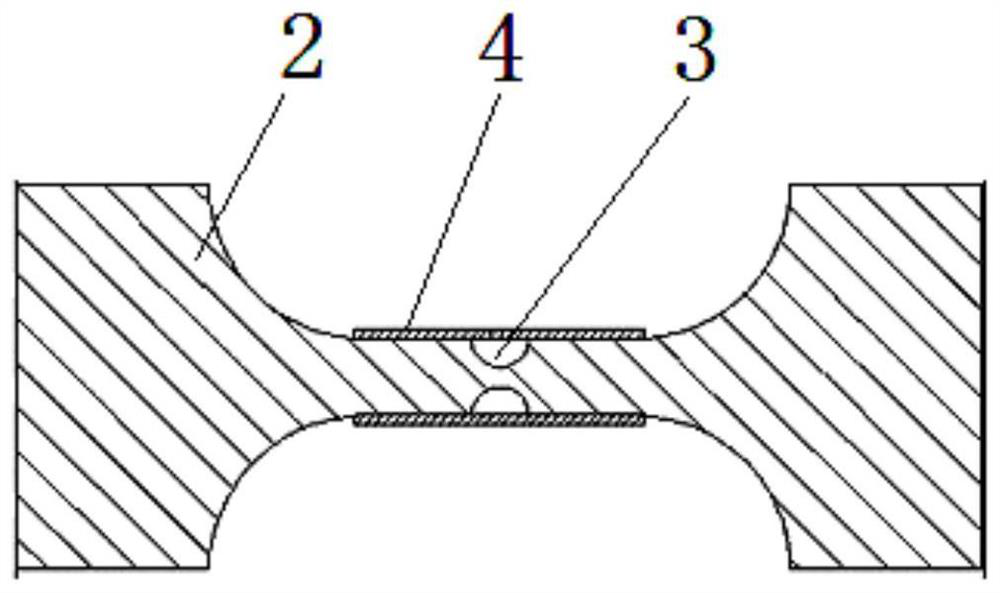

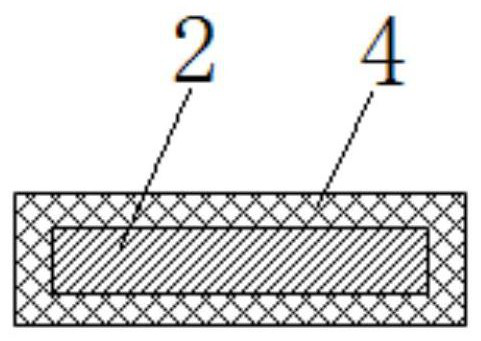

[0024] Composite melt, see figure 1 and figure 2 , including a conductive melt 2, the melt 2 is a long sheet structure, at least one narrow diameter 3 is arranged on the melt 2, and a layer of insulation covering the narrow diameter is provided at the outer peripheral surface of the narrow diameter 3 Protective layer 4, the two ends of the melt are located outside the insulating protective layer. When there are multiple narrow diameters on the melt, if the distance between each narrow diameter is relatively wide, an insulating protective layer can be provided at each narrow diameter; An insulating protective layer is provided; or a plurality of slits are grouped, and an insulating protective layer is provided at each group of slits.

[0025] In order to better reduce the volume of the composite melt, it is optimal that the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com