BPSG film layer processing method and semiconductor intermediate product

A processing method and film layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as deviation and affect product quality, and achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

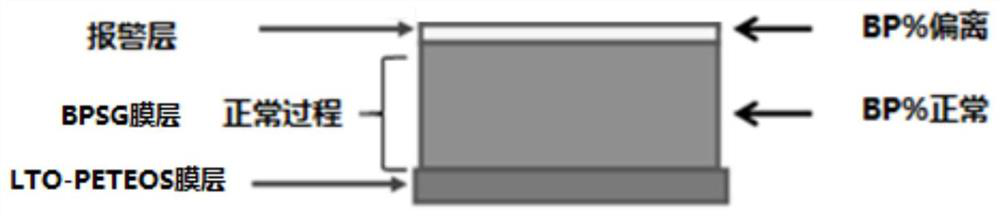

[0030] The BPSG process usually grows a layer of 2000A (Am, 1A=10A) on the wafer. -10 m) about LTO-PETEOS film layer, and then grow BPSG film layer on it, under normal circumstances, the resulting products produced after the completion of the BPSG process are as follows figure 1 shown. When the BPSG process is interrupted due to rule parameter changes or machine alarms, the resulting products at this time are as follows: figure 2 As shown, the film quality of the BPSG film layer grown during and at the end of the process interruption (ie figure 2 The film quality of the film layer grown during the normal process will be very different, especially the content of BP% will be very different. At this time if in figure 2 On the basis of the target thickness, directly rework and grow the BPSG film layer with the remaining thickness, which will cause a layer of alarm layer with different BP% concentration and different film quality in the middle of the BPSG film layer, and the ...

Embodiment 2

[0045] This embodiment is further improved on the basis of Embodiment 1. Such as Figure 5 Shown, this BPSG membrane treatment method comprises the steps:

[0046] S201. Measure the thickness of the BPSG film layer in the resulting product after the interruption of the BPSG process, and calculate the time required for dry etching and etching of the BPSG film layer; calculate the time required for dry etching and etching of the LTO-PETEOS film layer through the first thickness required time.

[0047] Such as Figure 6 As shown, the BPSG process usually grows a layer of LTO-PETEOS film layer of about 2000A on the wafer, and then grows the BPSG film layer on it (the wafer is omitted in the figure). The dry method of these two film layers The etching rate is different. The dry etching rate of the LTO-PETEOS film layer is 3300A / min (A / min), and the dry etching rate of the BPSG film layer is 6000A / min.

[0048] Before carrying out dry etching, measure the thickness of the BPSG f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com