Preparation process of a liner-lined copper-aluminum transition clamp

A technology for preparation process and transition line, which is applied in the field of preparation process of embedded liner-type copper-aluminum transition line clamp, can solve the problems of accelerating the downward movement of molten aluminum, and achieve the effects of reducing pore volume, accelerating downward movement, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

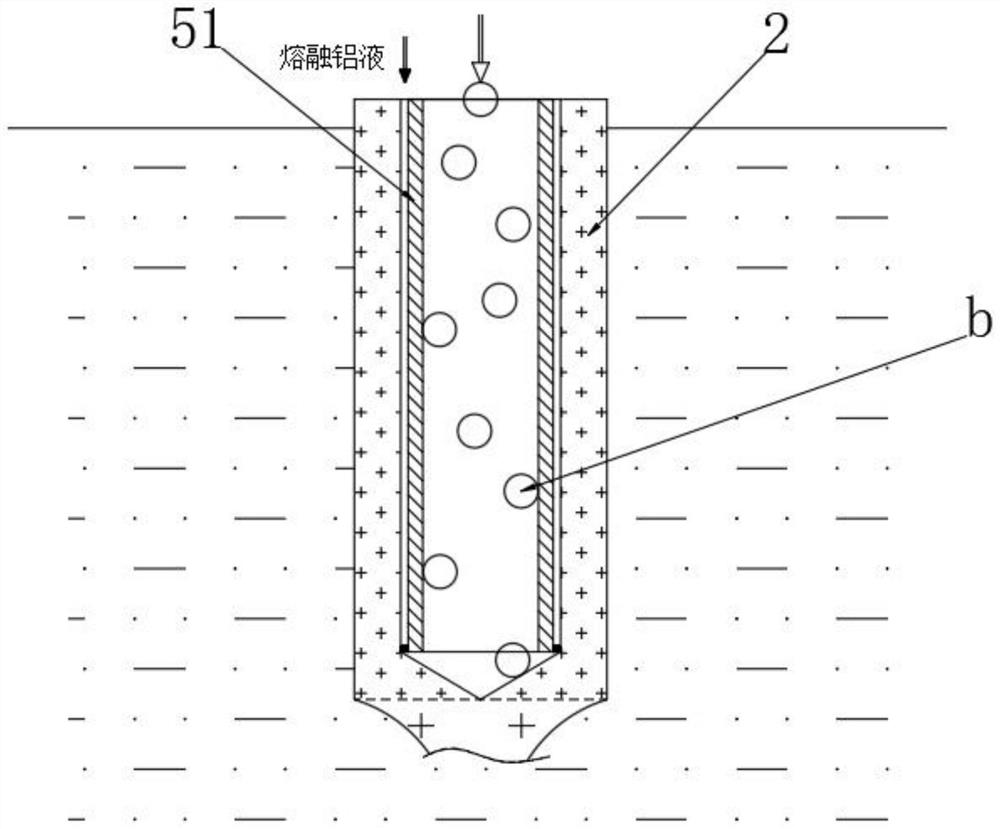

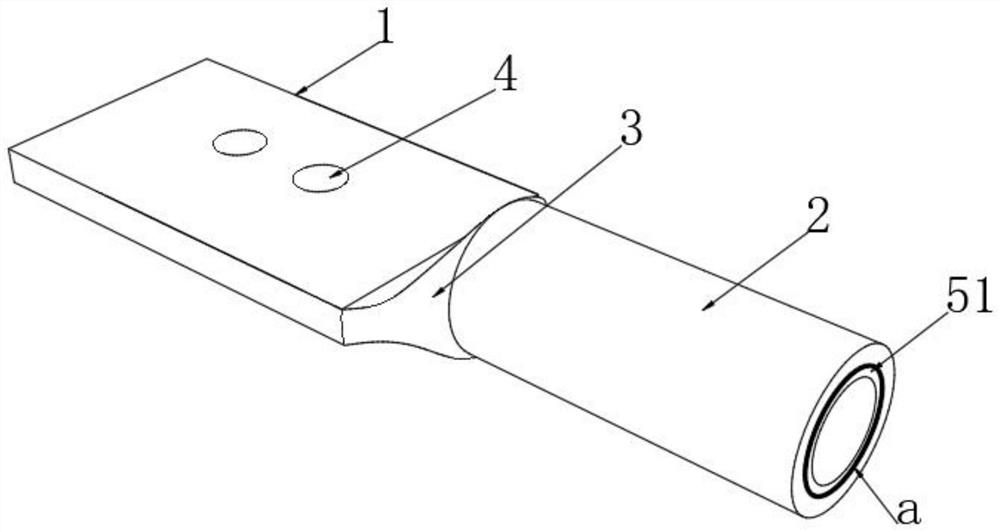

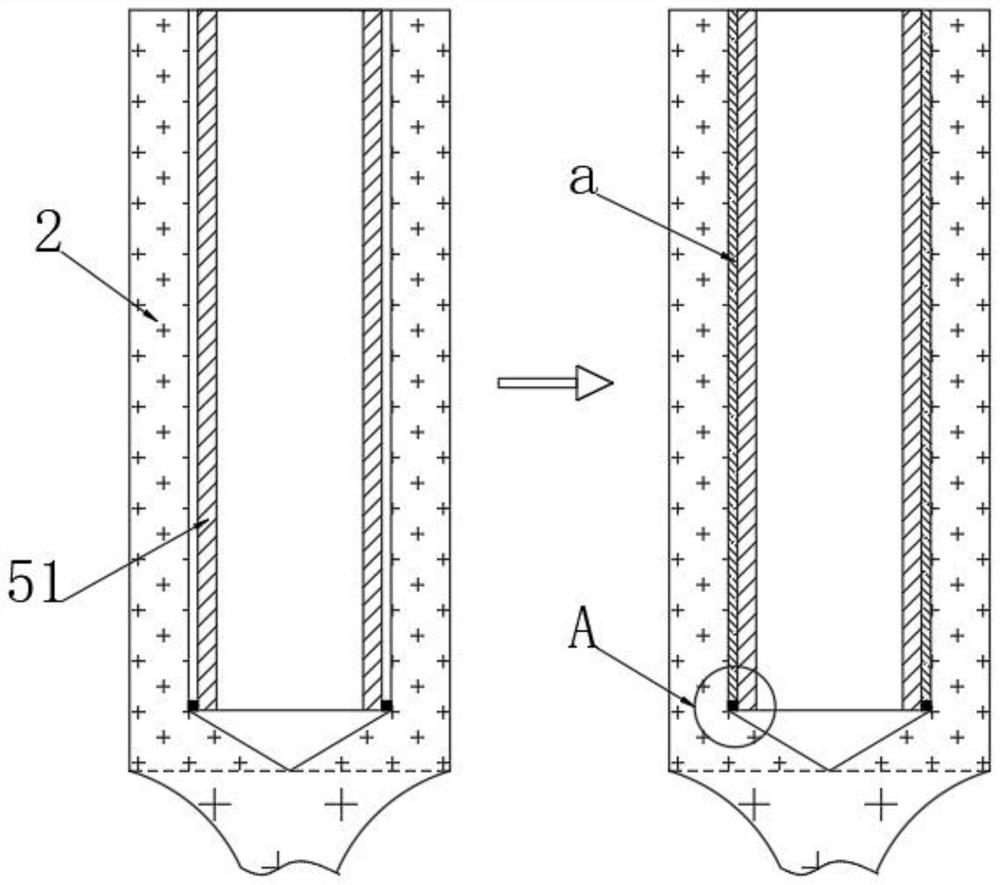

[0045] see figure 1 , see figure 2 , figure 2 The middle a represents the welding layer, a preparation process of the liner-embedded copper-aluminum transition clamp. The copper-aluminum transition clamp includes a copper splint 1 with two installation holes 4, a terminal post 2 and a copper splint 1 connected to it. The transition layer 3 between the terminal 2 and the inner wall of the terminal 2 is welded with an aluminum bushing 51, and the deepest part of the inner wall of the terminal 2 is a tapered structure. The preparation process includes the following steps:

[0046] S1. First, the inner surface of the wire clip body is degreased and derusted. The wall thickness of the wire clip body is consistent with the wall thickness of the prior art, but the inner diameter and outer diameter are enlarged to facilitate the embedding of the aluminum bushing 51 , and the inner diameter of the aluminum bushing 51 is consistent with the inner diameter of the existing clamp;

[...

Embodiment 2

[0056] see Image 6 The welding range between the aluminum bushing 51 and the clamp body is the straight inner wall and the tapered inner wall of the terminal 2, one end of the aluminum bushing 51 is a tubular structure with a conical compact structure, and the aluminum bushing 51 is close to the tapered A plurality of limit blocks 53 are fixedly connected to the outer end of one side, and the plurality of limit blocks 53 can be used to support the aluminum bushing 51 on the one hand, so that the space between the aluminum bush 51 and the inner wall of the terminal 2 can be evenly vacated. In order to effectively ensure the uniformity of the formed welding layer, on the other hand, the gaps between the plurality of limit blocks 53 facilitate the infiltration of molten aluminum, so that it is compatible with the conical shape of the aluminum bushing 51 Between the end portion and the tapered inner wall of the terminal 2, the range of the solder layer formed can be effectively e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com