Immersion type heat dissipation equipment for cooling network equipment and heat dissipation method of immersion type heat dissipation equipment

A technology of network equipment and heat dissipation equipment, which is applied in the construction of electrical equipment components, modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve the problems of inconvenient disassembly and assembly of parts, poor practicability, etc. Easy to install, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

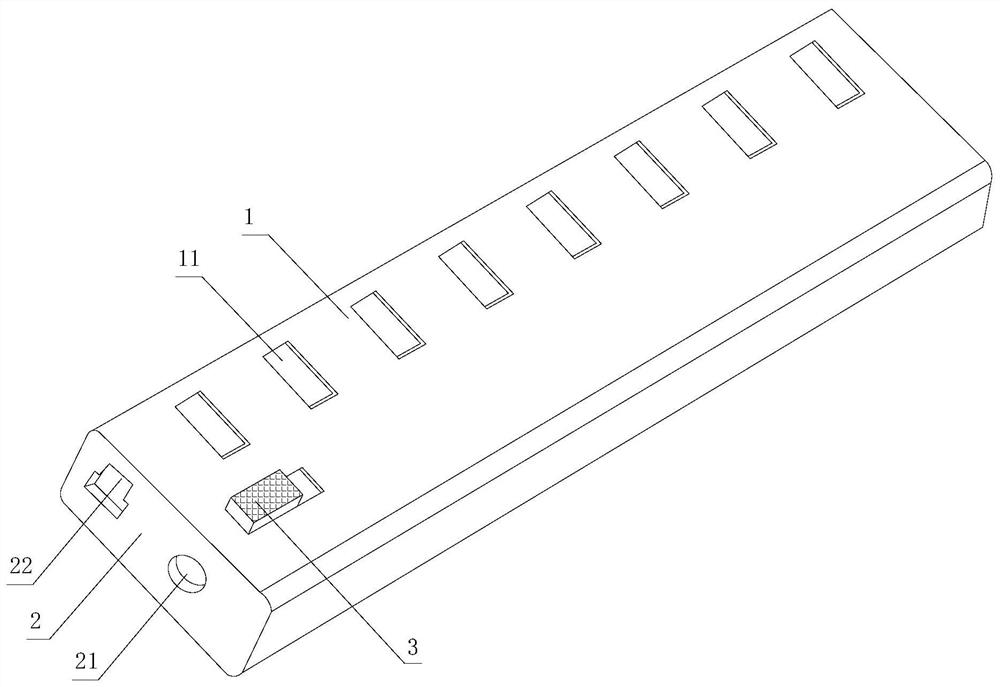

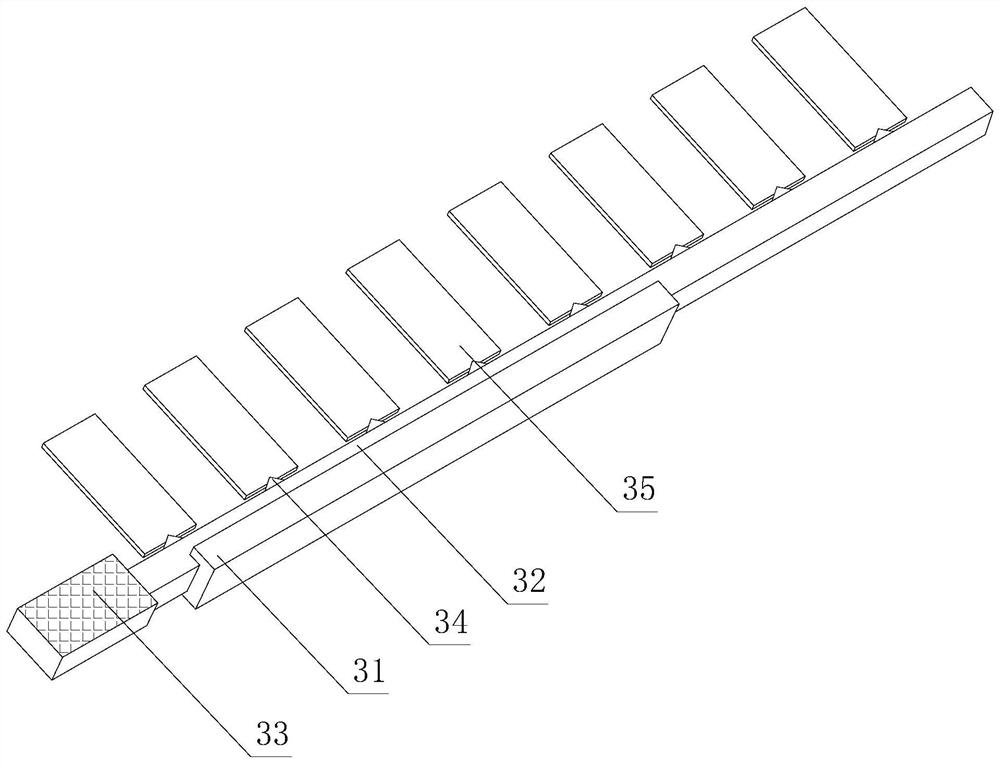

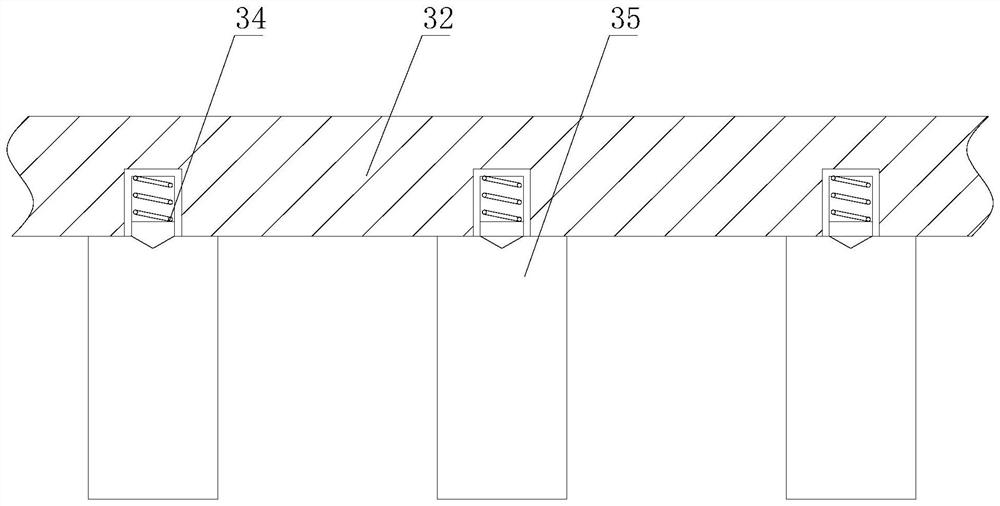

[0034] see Figure 1-8 , an immersion heat dissipation device for network equipment cooling, including a water diversion assembly 1, a heat dissipation assembly 2, and a circulating liquid storage tank 3, wherein the water diversion assembly 1 guides the cooling liquid to the heat dissipation assembly 2, which can better help the heat dissipation assembly 2 For heat dissipation, the water diversion assembly 1 is located on one side of the heat dissipation assembly 2. The heat dissipation assembly 2 is in contact with the top edge of the circulating liquid storage tank 3. The heat dissipation assembly 2 is overlapped on the top of the circulating liquid storage tank 3. The disassembly and assembly of the heat dissipation assembly 2 is convenient. The heat dissipation assembly 2 extends into the inner cavity of the circulating liquid storage tank 3, so that good heat dissipation can be carried out. The heat dissipation assembly 2 includes a heat exchange plate 21, a transition pl...

Embodiment 2

[0037] see Figure 1-7 and Figure 9, an immersion heat dissipation device for network equipment cooling, including a water diversion assembly 1, a heat dissipation assembly 2, and a circulating liquid storage tank 3, wherein the water diversion assembly 1 guides the cooling liquid to the heat dissipation assembly 2, which can better help the heat dissipation assembly 2 For heat dissipation, the water diversion assembly 1 is located on one side of the heat dissipation assembly 2. The heat dissipation assembly 2 is in contact with the top edge of the circulating liquid storage tank 3. The heat dissipation assembly 2 is overlapped on the top of the circulating liquid storage tank 3. The disassembly and assembly of the heat dissipation assembly 2 is convenient. The heat dissipation assembly 2 extends into the inner cavity of the circulating liquid storage tank 3, so that good heat dissipation can be carried out. The heat dissipation assembly 2 includes a heat exchange plate 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com