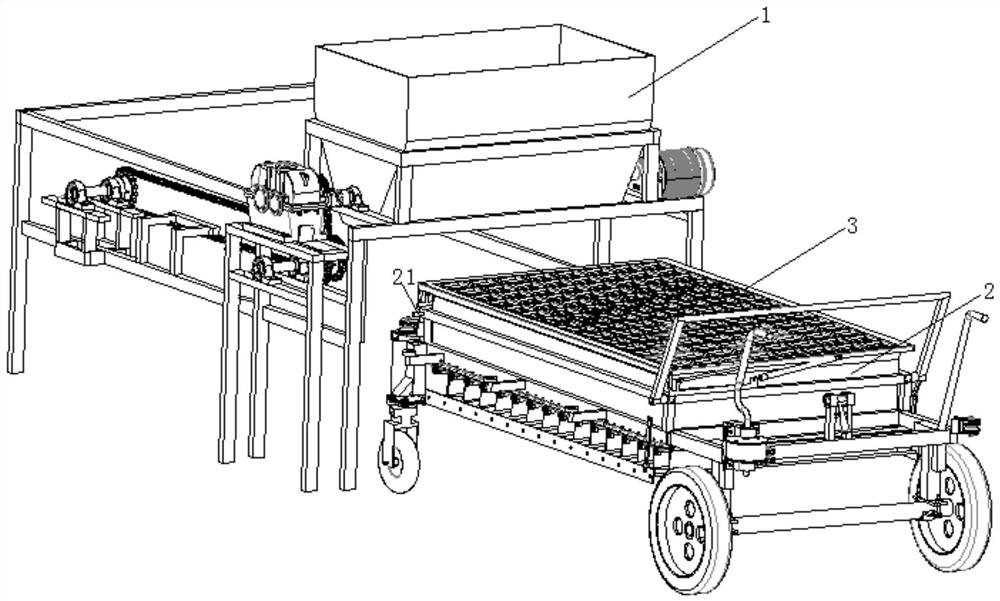

Seedling culture bowl filling and transferring device convenient in filling

The technology of a transfer device and a seedling pot is applied in the filling of flowerpots, botanical equipment and methods, gardening and other directions, which can solve the problems of low efficiency, long time consumption, inconvenient use, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

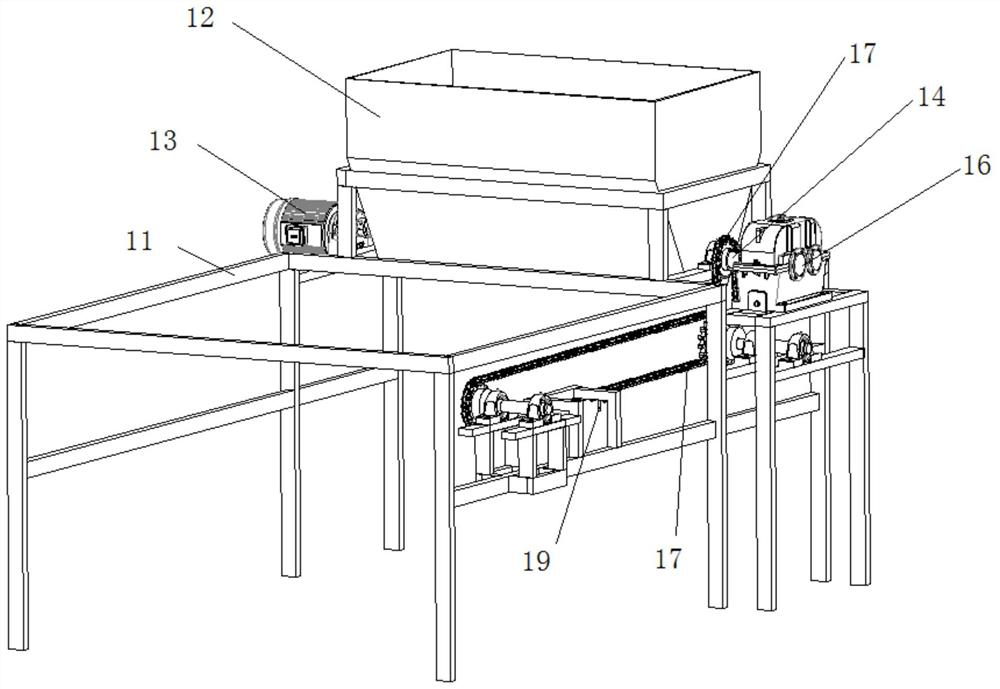

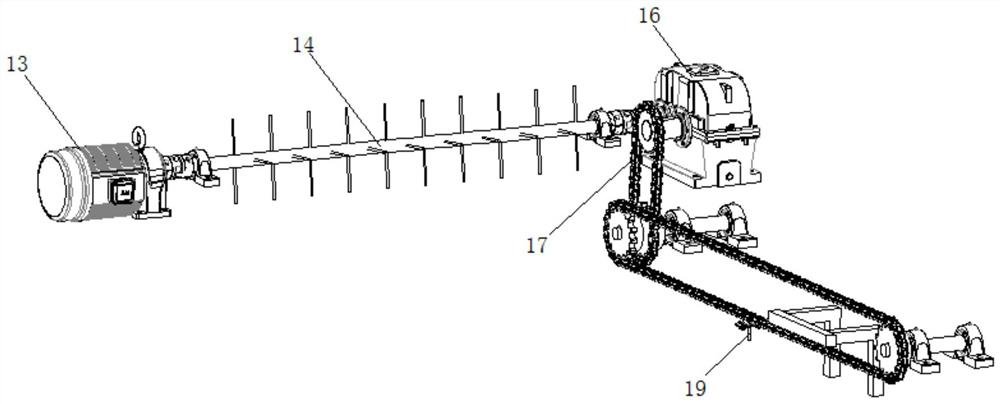

[0027] As an embodiment, the storage and unloading mechanism includes a silo 12 and a stirring mechanism. The silo 12 is funnel-shaped with openings up and down. The warehouse gate is used to adjust the opening size of the lower end of the material bin 12. The stirring mechanism includes a motor 13, a main transmission shaft 14 and a stirring rod 15. A plurality of stirring rods 15 are evenly arranged on the outer side of the main transmission shaft 14 radially. The main transmission shaft 14 is arranged horizontally, the stirring rod 15 is located below the inside of the silo 12, and the motor 13 is arranged at one end of the main transmission shaft 14 and is used to drive the main transmission shaft 14 to rotate around the axis.

[0028] As an embodiment, the pulling mechanism includes a reducer 16, a vertical sprocket transmission mechanism 17 and a horizontal sprocket transmission mechanism 18, the input end of the reducer 16 is connected to the main transmission shaft 14, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com