Apparatus and method for coating elastic glue on optical window

A technology for optical windows and coating devices, which is applied to devices and coatings that apply liquid to surfaces, can solve the problems of scratches on optical windows of coating tools, increased friction of foam support, and increased operational safety risks, etc. To achieve the effect of reducing the workload of wiping, improving uniformity, avoiding environmental pollution and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0048] In order to solve the above technical problems, the present invention provides a high-efficiency rotary support device and method for coating elastic glue on optical windows. The device and method use a rotating support device to quickly position the optical window, and use an improved coating tool to divide and coat point-type elastic glue according to a certain distance to complete the entire coating work.

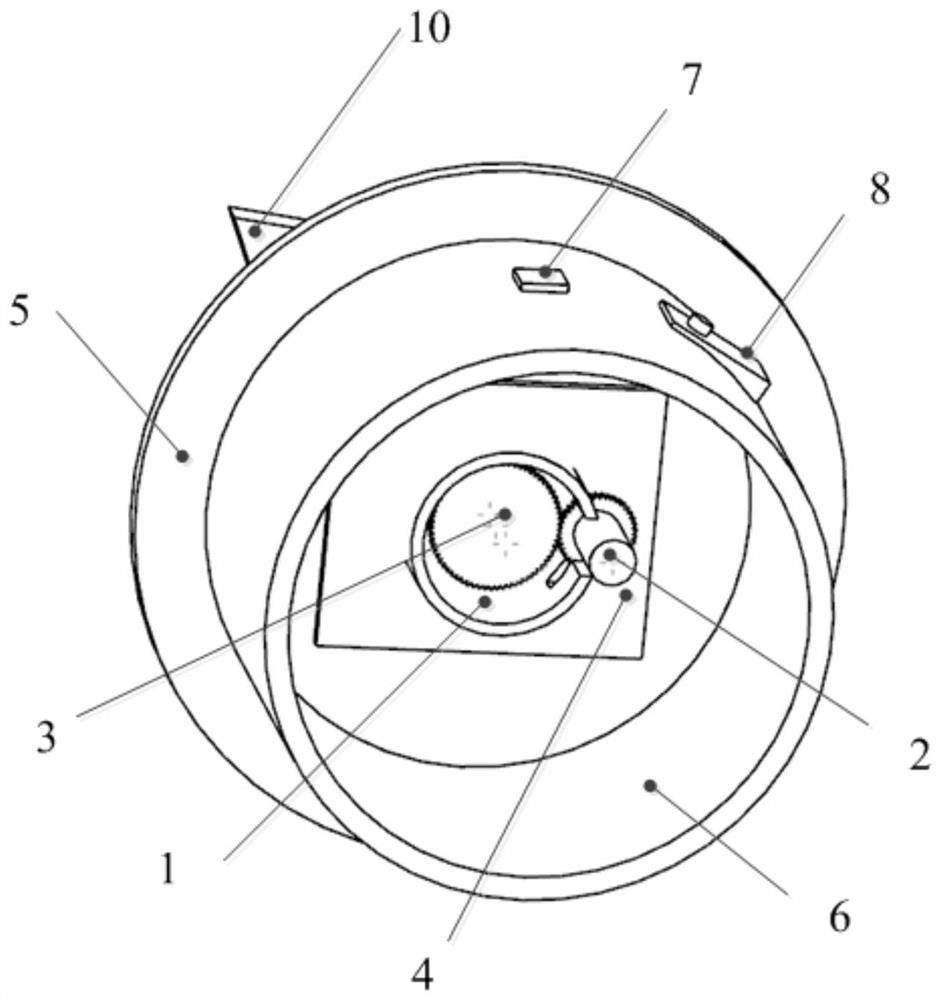

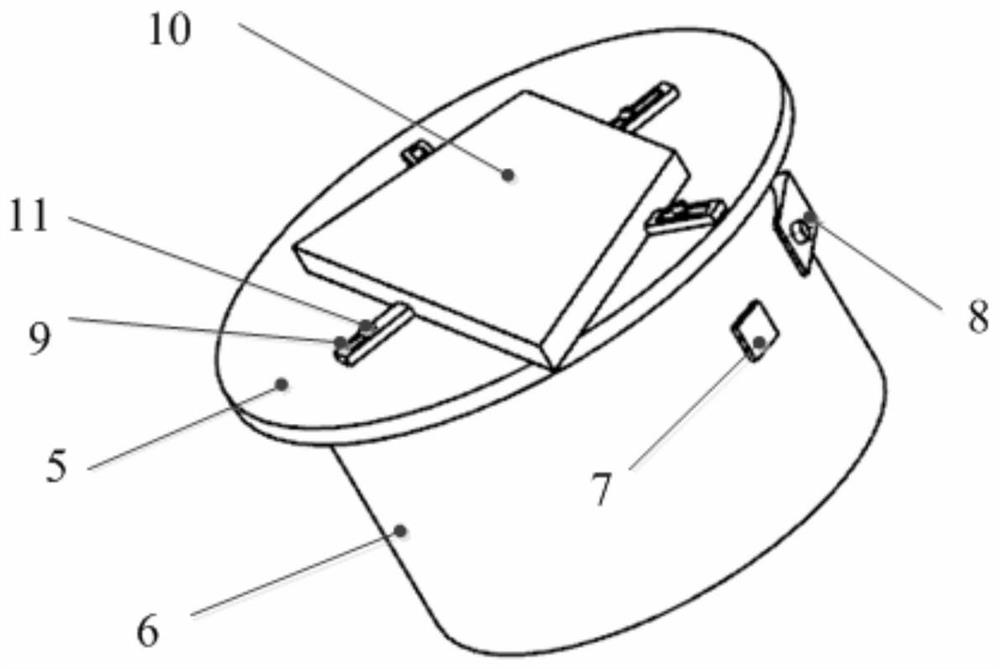

[0049] Specifically, as figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 As shown, the elastic glue coating device for the optical window includes: a supporting device and a coating tool;

[0050] The support device includes: a support seat 1, a motor 2, a rotating shaft system 3, a fixed plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com