Water-making oxygen generator

An oxygen generator and oxygen storage tank technology, applied in the field of oxygen generators, can solve the problems of single function, reducing the adsorption efficiency of molecular sieves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

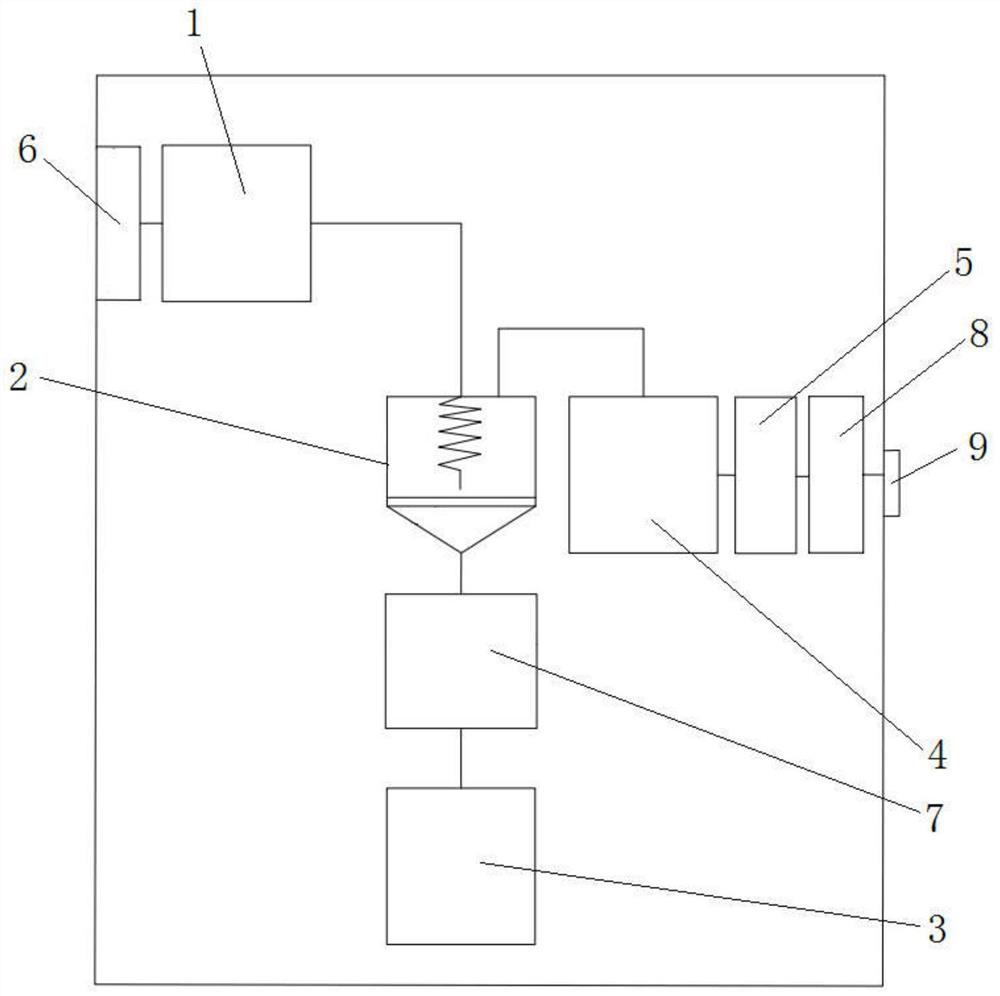

[0026] see figure 1 as well as figure 2 , a water and oxygen generator, including a compressor 1, a water-gas separation assembly 2, a water collection bottle 3, a molecular sieve assembly 4 and an oxygen storage tank 5, the water-gas separation assembly 2 includes an air inlet, a water outlet and an air outlet, The molecular sieve assembly 4 includes a molecular sieve assembly air inlet and a molecular sieve assembly air outlet, the compressor 1 is connected to the air inlet of the water-gas separation assembly 2, and the water outlet of the water-air separation assembly 2 is connected to the water sampling bottle 3 The air outlet of the water-gas separation assembly 2 is connected to the air inlet of the molecular sieve assembly 4, and the air outlet of the molecular sieve assembly 4 is connected to the oxygen storage tank 5.

[0027] In this embodiment, the air enters the interior of the compressor, and the compressor compresses the air to obtain high-temperature and high...

Embodiment 2

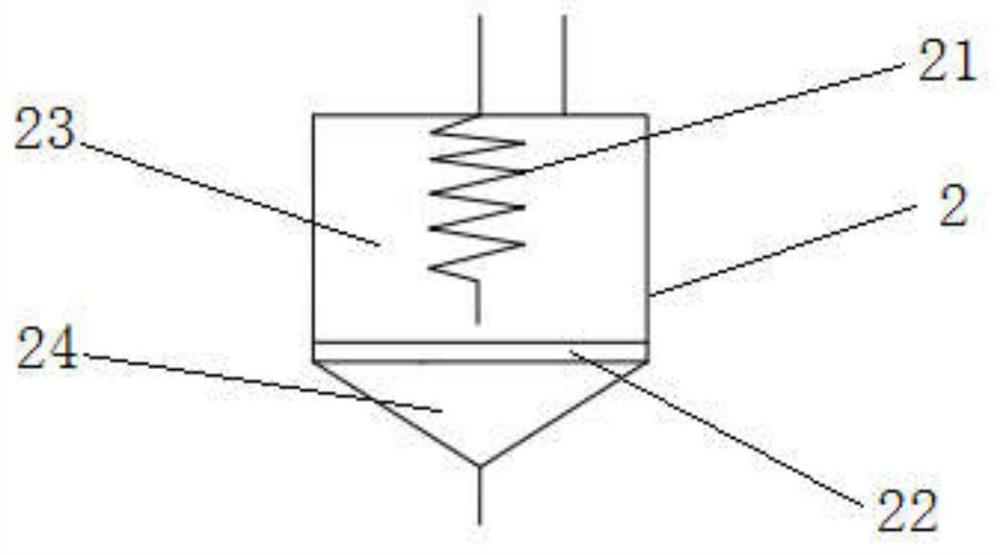

[0030] On the basis of Embodiment 1, the water-gas separation assembly 2 includes a housing, and an accommodating chamber is formed in the housing, and the cooling pipe 21 extends through the housing into the interior of the accommodating chamber, The water nanofiltration screen 22 is arranged in the accommodating cavity, and the accommodating cavity is divided into a gas chamber 23 and a liquid chamber 24 by the water nanofiltration sieve 22, and the air inlet passes through the cooling tube 21 communicates with the gas chamber 23, the liquid chamber 24 communicates with the water outlet, and the top of the gas chamber 23 is provided with an air outlet.

[0031] In this embodiment, the high-temperature and high-pressure gas is cooled through the cooling tube to obtain normal-temperature and high-pressure gas. When the normal-temperature and high-pressure gas passes through the water nano-filtration sieve, the gas in the air is blocked, and the water molecules are separated thr...

Embodiment 3

[0035] On the basis of Example 2, the cooling tube 21 is a metal aluminum tube.

[0036] In this embodiment, aluminum metal, as a good heat-conducting metal, can quickly and effectively transfer heat, and the use of metal aluminum tubes to cool the high-temperature and high-pressure gas can speed up the cooling process of the high-temperature and high-pressure gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com