Patterned electronic light source device based on anodized aluminum template and its manufacturing method

A technology of anodized aluminum and aluminum oxide templates, applied in the field of electronics, can solve the problems of high cost of masks, limited development and application, and low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

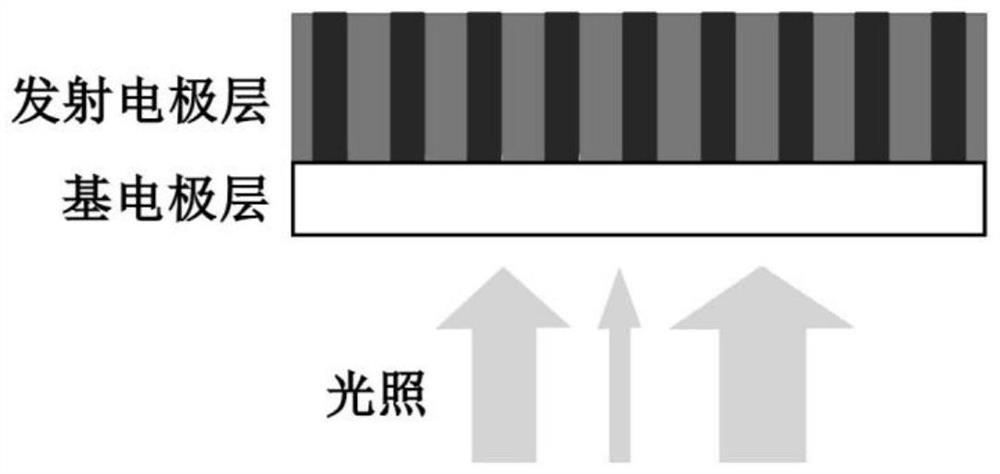

[0043] A patterned electron light source device based on an anodized aluminum template, including two parts: an electron emitter and a light projection irradiation system. The light projection irradiation system adopts the projection system of ordinary light lithography. The cross-sectional view of the electron emitter is shown in figure 1 shown. The emitter consists of two parts: the base electrode layer, which is a transparent conductive layer, and ITO (indium tin oxide) can be used; the emitter electrode layer, the black part is the nano-electrode array for depositing the inner photoelectric effect material, and the white part is the aluminum oxide template skeleton.

[0044] When the light projection irradiation system projects the preset pattern from the back onto the electron emitter, since the emitter contains a nano-electrode array of inner photoelectric effect material, the irradiated nano-electrode will generate photogenerated electrons and holes without The nanoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com