Vortex liquid pump capable of preventing pressure pulsation

A technology of pressure pulsation and moving vortex, applied in the direction of rotary piston/oscillating piston pump components, rotary piston pumps, pumps, etc., can solve problems such as inapplicability, complex system structure, and increased leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

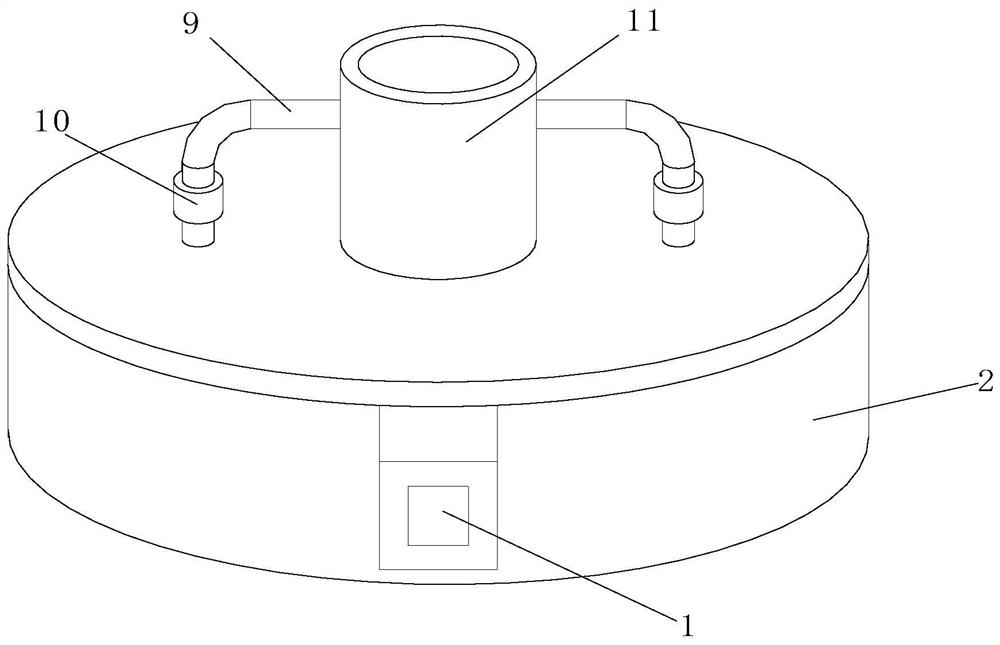

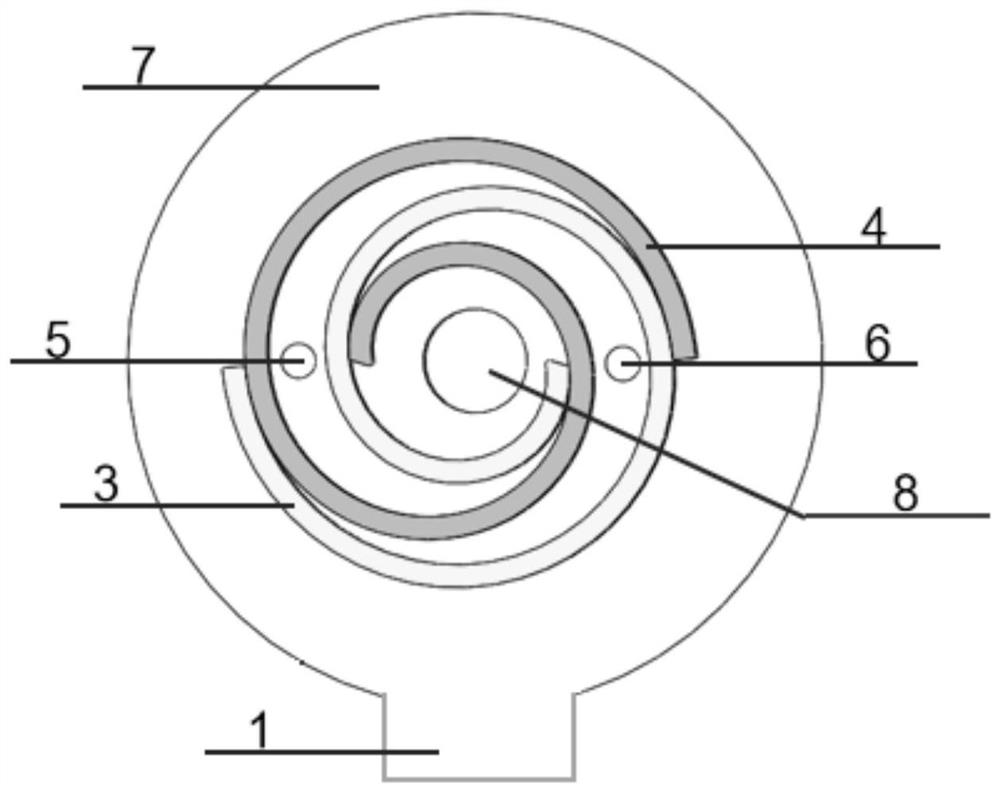

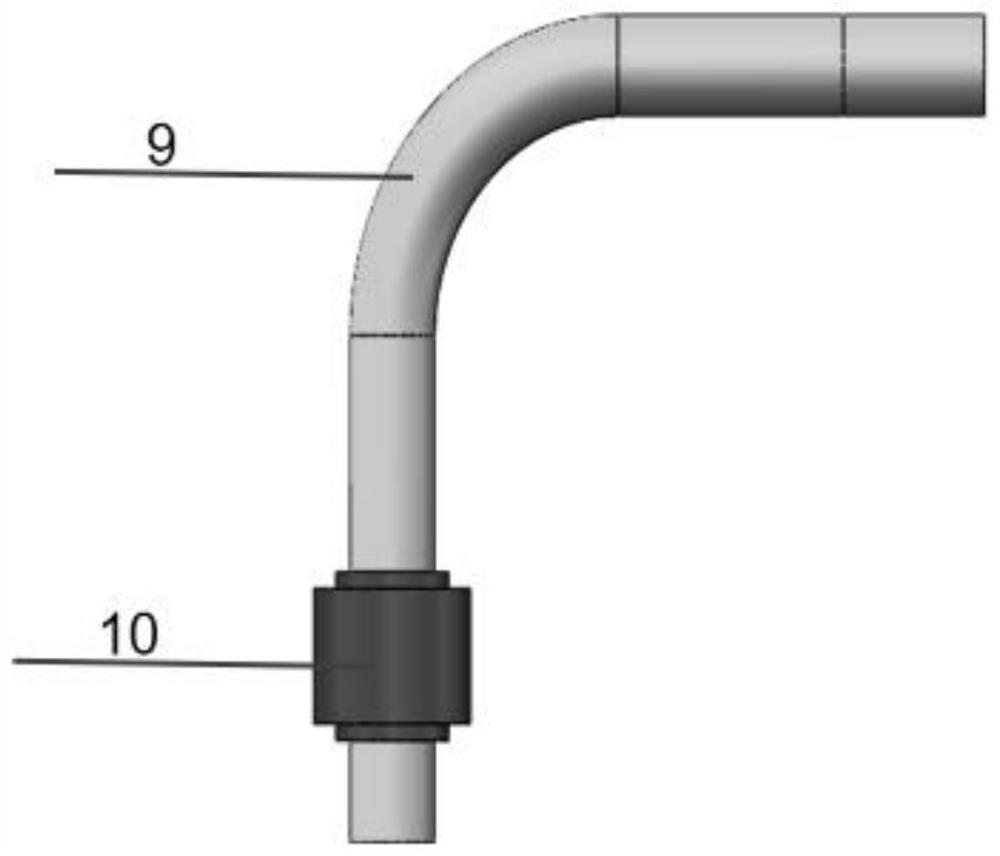

[0030] Such as Figure 1-4 As shown, the present invention is a scroll pump that prevents pressure pulsation, including a support housing 2, a static scroll 3, a movable scroll 4, a static scroll end cover 7, and the static scroll 3 The fixed scroll end cover 7 is fixed, and the movable scroll 4 is disposed in the support housing 2, and the support housing 2 and the static scroll end cover 7 form a closed cavity and the static scroll 3, The scroll 4 is disposed within the enclosed cavity; the movable scroll 4 is mounted between 180 ° phase angles and forms a moon-shaped working chamber between 180 ° phase angles and the static scroll 3; the movable scroll 4 is connected The mechanism, the movable scroll 4 is rotationally moved by the power mechanism to the static scroll 3; there is a discharge port 8 in the middle of the static scroll end cap 7, and the support housing 2 is provided with an inlet port. 1; the closed chamber is provided with a pressure regulation structure that adju...

Embodiment 2

[0034] Such asFigure 5-7 As shown, a scroll pump that prevents pressure pulsation includes a support housing 2, a static scroll 3, a movable scroll 4, a static scroll end cover 7, and the static scroll 3 is fixedly disposed. On the scroll end cover 7, the movable scroll 4 is disposed within the support housing 2, and the support housing 2 and the static scroll end cover 7 form a closed cavity and the static scroll 3, the scroll rotary disc 4 is disposed within the enclosed cavity; the movable scroll 4 is mounted between 180 ° phase angles and forms a pitch working chamber between 180 °; the movable mechanism is connected. The scroll 4 is rotationally motion in the drive of the power mechanism, and a discharge port 8 is provided in the middle of the static scroll end cap 7, and a support housing 2 is provided with an inlet 1; enclosed An adjustment of the moonstone working chamber pressure is provided in the cavity.

[0035] The pressure regulating structural pressure regulating st...

Embodiment 3

[0039] A scroll pump that prevents pressure pulsation, including support housing 2, static scroll 3, movable scroll 4, static scroll end cover 7, said static scroll 3 fixedly disposed in a static scroll On the end cap 7, the movable scroll 4 is disposed within the support housing 2, and the support housing 2 is fitted with the static scroll end cap 7 to form a closed cavity and the static scroll 3, and the scroll 4 is disposed. In the enclosed cavity; the movable scroll 4 and the static scroll 3 are mounted in a 180 ° phase angle and form a pair of moon tooth working cavity; the movable scroll 4 is connected to a power mechanism, a movable scroll 4 In the drive of the power mechanism, the swivel vortex 3 is rotationally moved; and there is a discharge port 8 in the middle portion of the static scroll end cover 7, and the support housing 2 is provided with an inlet port 1; enclosed in the cavity There is a pressure regulating structure that adjusts the moonstone working chamber pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com