An electro-hydraulic control device for an anti-escape restraint device

A restraint device and electro-hydraulic control technology, which is applied in the direction of fluid pressure actuation device, servo motor, mechanical equipment, etc., can solve the problems of poor blood circulation of the local skin, physical damage of the restrained object, and difficulty in controlling the size of the restraint force. The effect of light weight, avoiding physical damage, ensuring safety and working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

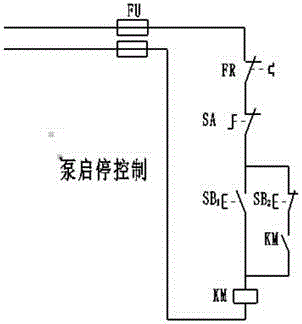

[0035] Embodiment 1: The system implementation mode of the electro-hydraulic control system.

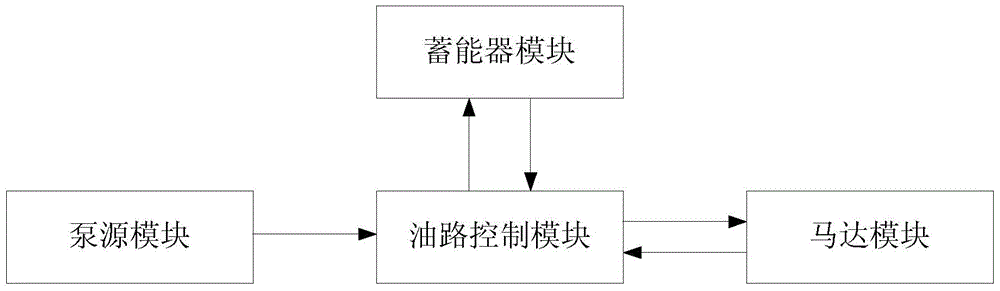

[0036] An electro-hydraulic control device of an anti-dropping restraint device, such as figure 1 As shown, including pump source module, oil circuit control module, accumulator module and motor module;

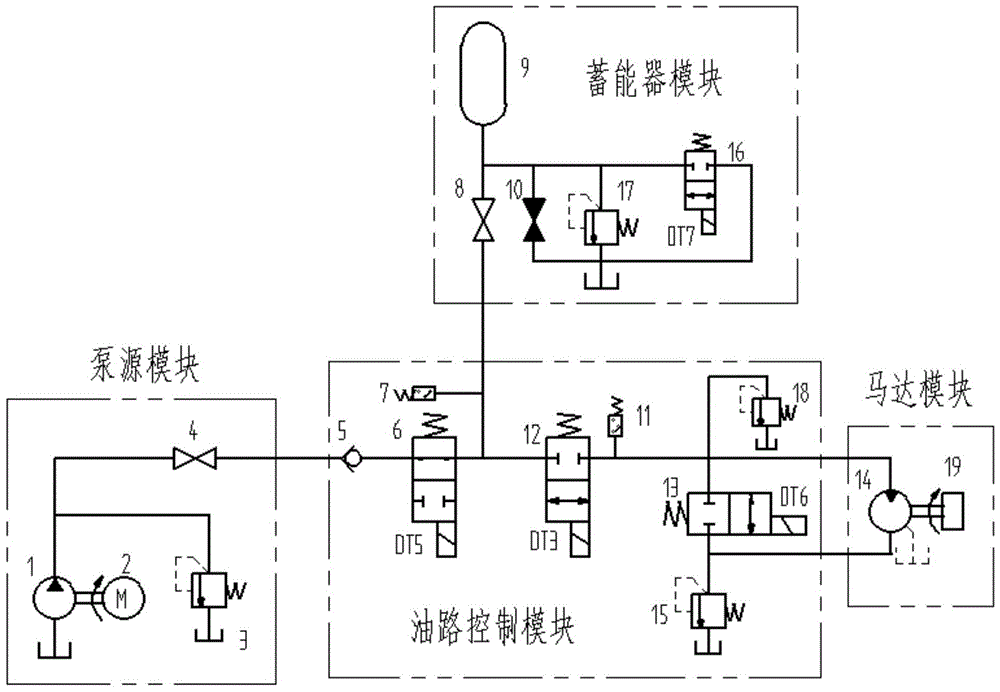

[0037] Such as figure 2 As shown: the pump source module includes a hydraulic pump 1, a motor 2, a first relief valve 3 and a first stop valve 4. The hydraulic pump 1 and the motor 2 are connected by a coupling, and the inlet of the hydraulic pump 1 is connected to the oil tank, Its outlet is connected to the first relief valve 3, and the oil return port of the first relief valve 3 is connected to the oil tank. At the same time, the outlet of the hydraulic pump 1 is connected to the first stop valve 4, and the first stop valve 4 is connected to the one-way of the oil circuit control module. Valve 5;

[0038] The oil circuit control module includes a one-way valve 5, a first electromagnet...

Embodiment 2

[0046] The second embodiment: the implementation of the hydraulic control system.

[0047] A hydraulic control device of an anti-off restraint device, such as figure 1 As shown, including pump source module, oil circuit control module, accumulator module, motor module;

[0048] The pump source module and the motor module are the same as those in the hydraulic system of the electro-hydraulic control system.

[0049] Such as image 3 As shown, the oil circuit control module includes a one-way valve 20, a hydraulic reversing valve 21, a manual reversing valve 23, a second overflow valve 24, and a safety valve 22. One end of the one-way valve 20 is connected to the first pump module. A stop valve 4, the other end of which is connected to the hydraulic directional valve 21, the hydraulic oil is divided into three paths after passing through the hydraulic directional valve 21, of which: one path goes through the safety valve 22 and then returns to the tank, and the second path of hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com