Intelligent water supplying device for high-speed water bearing

A technology of intelligent water supply and water supply equipment, applied in water supply equipment, water supply equipment, buildings, etc., can solve the problems that are not suitable for high-speed hydrostatic pressure bearing lubrication, does not solve the water supply pressure pulsation, and can only reach several atmospheric pressures, etc., to achieve energy saving Good effect, eliminate pressure pulsation, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

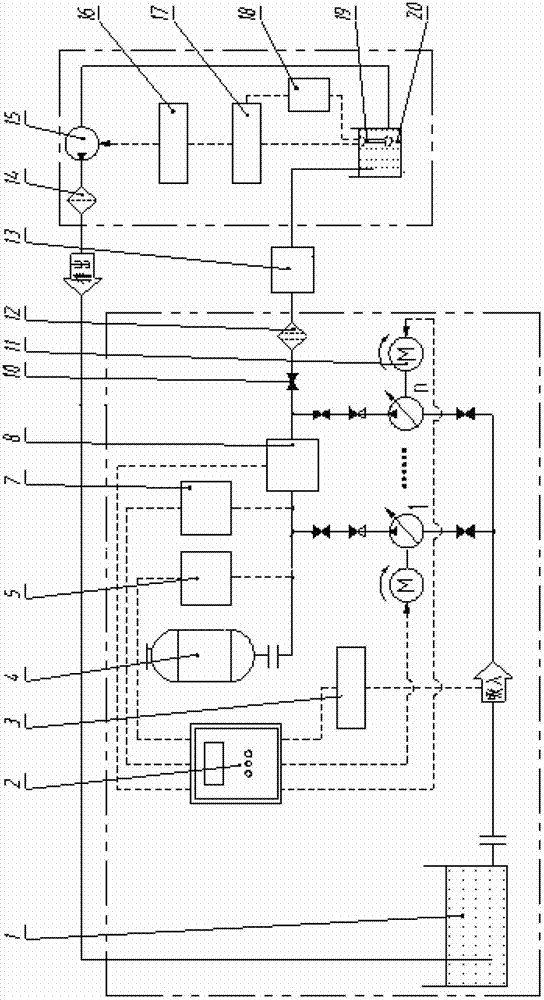

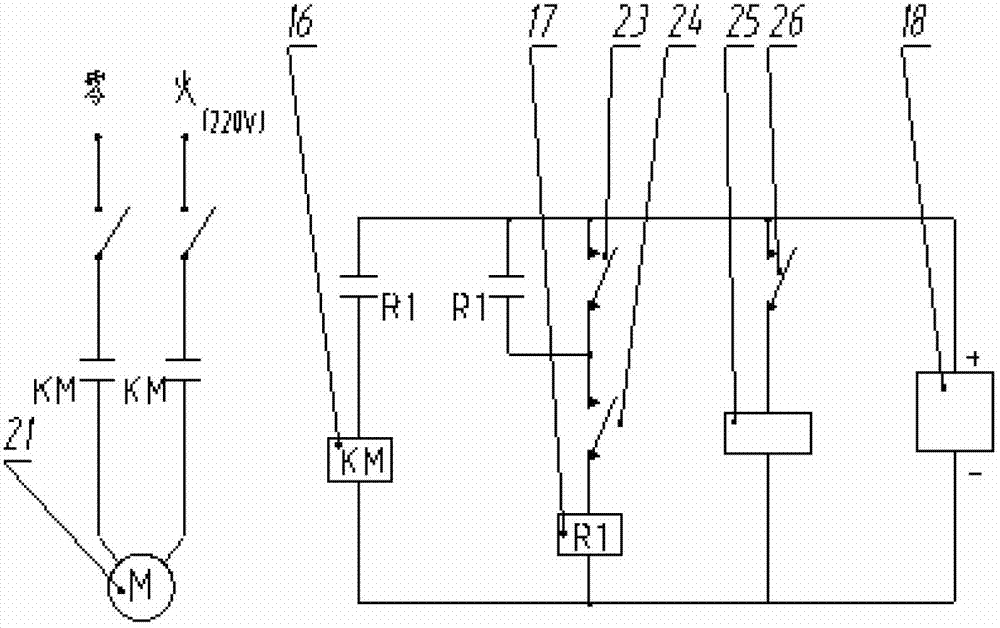

[0016] Such as figure 1 and 2 Shown: a high-speed water bearing intelligent water supply device, including a frequency conversion constant pressure water supply device and an automatic drainage device;

[0017] The water supply device mainly uses the frequency conversion control cabinet 2 to drive multiple parallel multi-stage water pump groups 11 to realize high-pressure water supply. When the water pump is just running, it sucks water from the large return water tank 1, and first fills up the diaphragm pressure tank 4 with water. When using water, the valve 10 is turned on, high-pressure water passes through the fine filter 12, and is supplied to the high-speed water bearing 13. At the same time, an electric contact pressure gauge 7 and an electric contact flow meter 8 are installed in the supply pipeline to display the water supply pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com