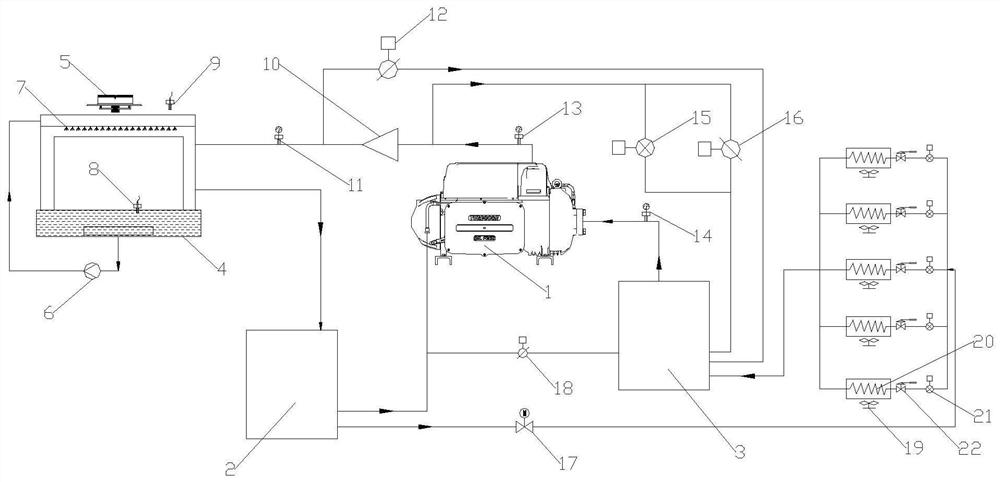

Magnetic suspension evaporative cooling direct expansion unit and control method thereof

A control method and magnetic levitation technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as inconvenient maintenance, unfavorable energy saving, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

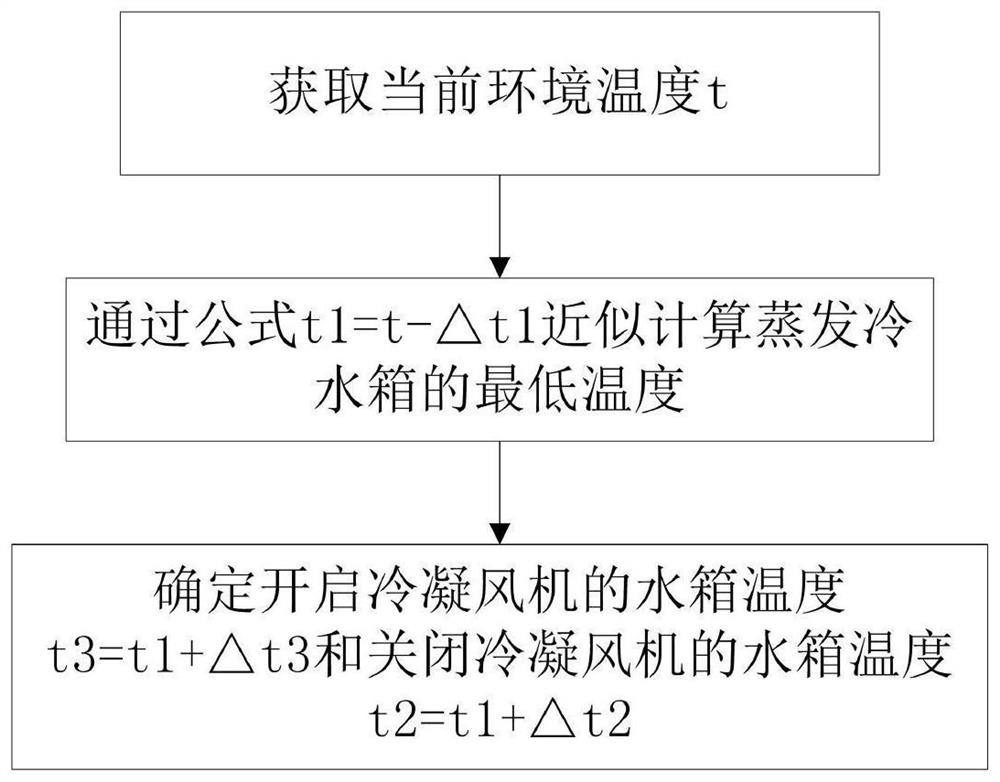

[0030] The aforementioned steps of "controlling the start and stop of the condensing fan according to the water temperature in the water tank and / or the pressure ratio of the maglev evaporative cooling and direct expansion unit" include: when the condensing fan is turned off, if the water temperature in the water tank rises to the first When the temperature threshold is reached, the condensing fan is turned on; when the condensing fan is turned on, if the water temperature in the water tank drops to the second temperature threshold, the condensing fan is turned off, and the first temperature threshold is greater than the second temperature threshold. That is, when the condensing fan is turned off and the water temperature in the water tank rises to the first temperature threshold, the condensing fan is turned on, and if the water temperature in the water tank does not drop to the second temperature threshold, the condensing fan is kept on. When the water temperature in the wate...

Embodiment 2

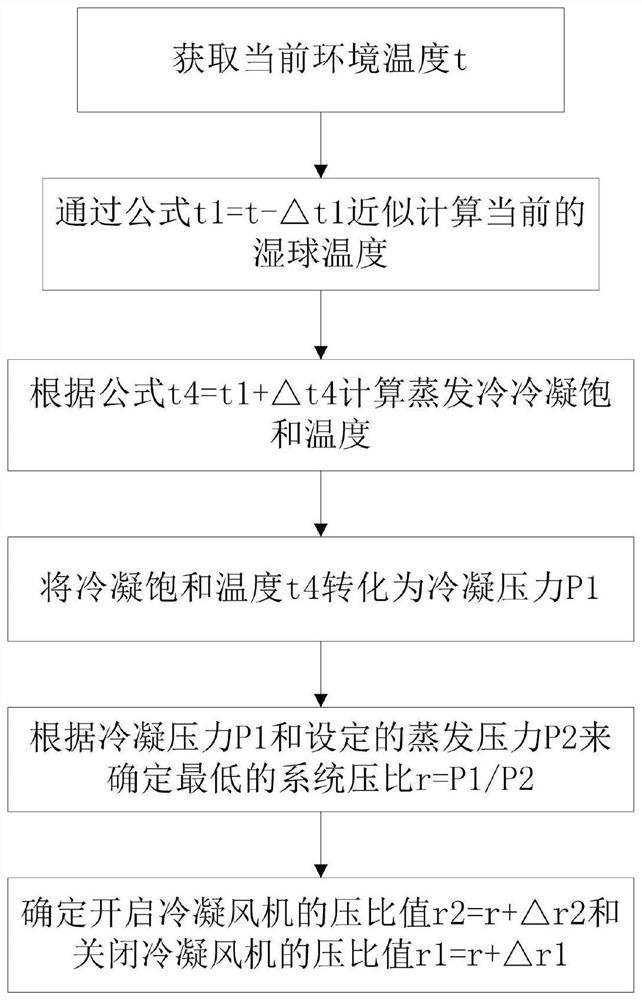

[0032] The aforementioned step of "controlling the start and stop of the condensing fan according to the water temperature in the water tank and / or the pressure ratio of the maglev evaporative cooling direct expansion unit" includes: when the condensing fan is closed, if the pressure ratio of the maglev evaporative cooling direct expansion unit When the condensing fan is turned on, if the pressure ratio of the maglev evaporative cooling and direct expansion unit drops to the second setting ratio, the condensing fan is turned off, and the first setting ratio greater than the second set ratio. That is, when the condensing fan is turned off and the pressure ratio of the unit rises to the first set ratio, the condensing fan is turned on, and if the pressure ratio of the unit does not drop to the second set ratio, the condensing fan is kept on. When the pressure ratio of the unit drops to the second set ratio, the condensing fan is turned off again; when the condensing fan is turne...

Embodiment 3

[0034] The aforementioned steps of "controlling the start and stop of the condensing fan according to the water temperature in the water tank and / or the pressure ratio of the maglev evaporative cooling and direct expansion unit" include: when the condensing fan is turned off, if the water temperature in the water tank rises to the first A temperature threshold or the pressure ratio of the maglev evaporative cooling direct expansion unit rises to the first set ratio, then the condensing fan is turned on; when the condensing fan is turned on, if the water temperature in the water tank drops to the second temperature threshold and the maglev evaporative cooling When the pressure ratio of the direct expansion unit drops to the second set ratio, the condensing fan is turned off. That is, when the water temperature in the water tank and the pressure ratio of the unit meet the conditions for turning off the condensing fan at the same time, the condensing fan is turned off; when the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com