X-ray inspection apparatus and x-ray inspection method

A technology for inspection devices and inspection methods, applied to measuring devices, material analysis using radiation diffraction, nuclear radiation exploration, etc., can solve problems such as difficult X-ray foreign matter inspection, inability to correct correctly, difficult calibration, etc., and achieve high The effect of detection accuracy, continuous and efficient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

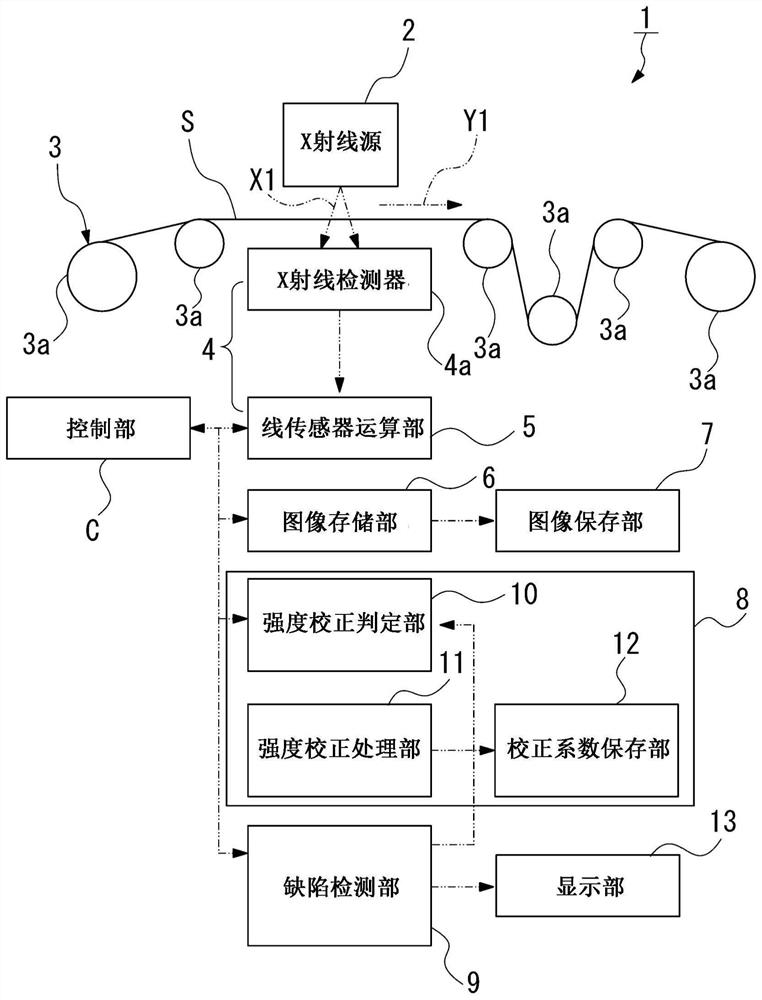

[0042] Below, refer to Figure 1 to Figure 8 One embodiment of the X-ray inspection apparatus and X-ray inspection method of the present invention will be described.

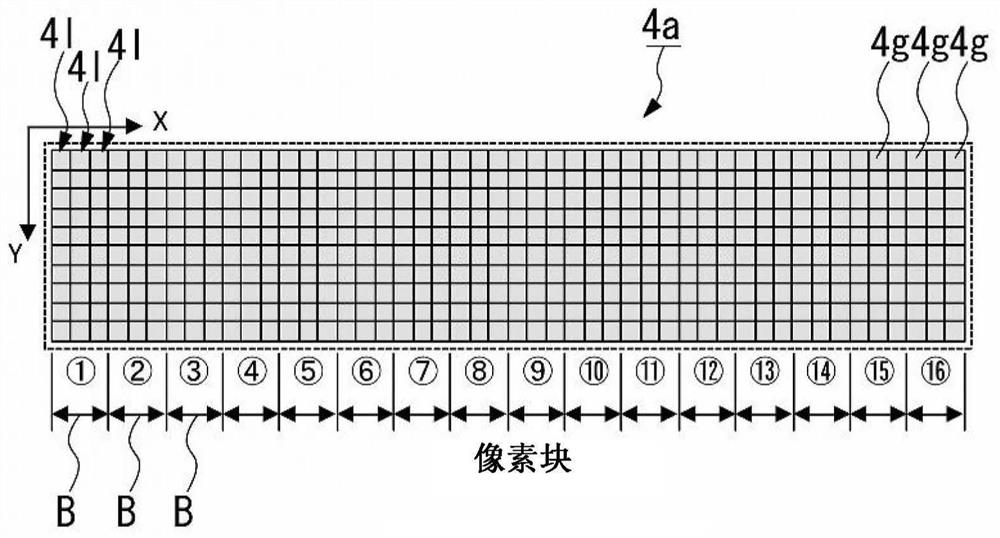

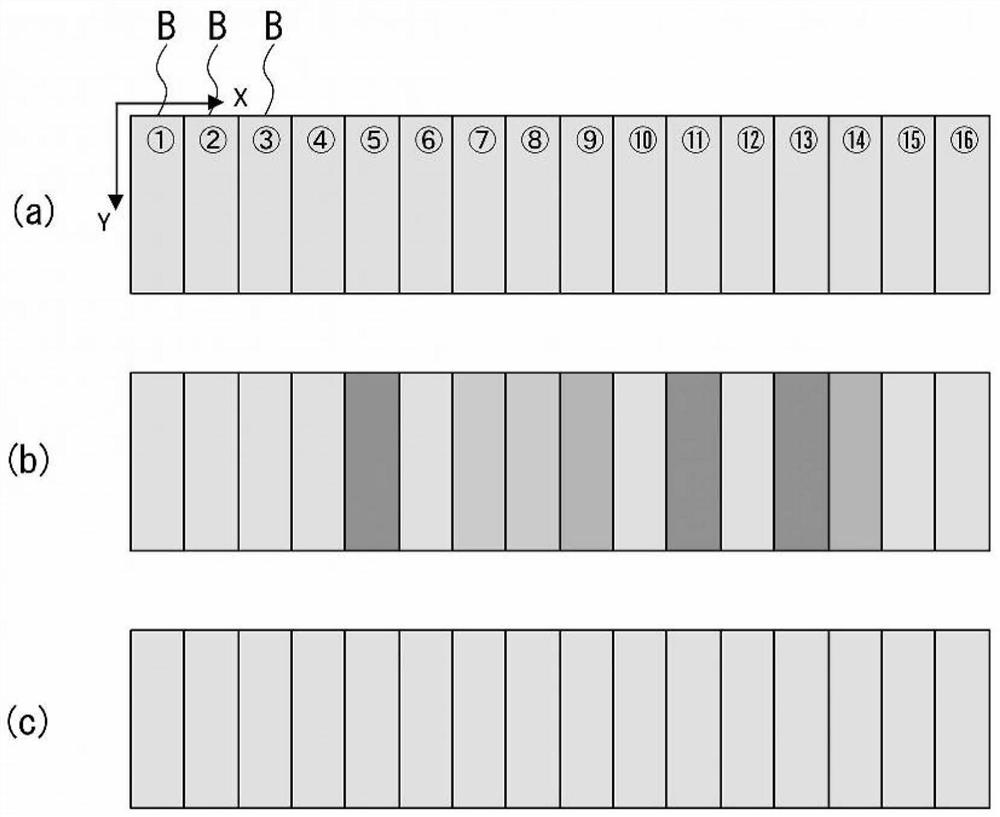

[0043] Such as figure 1 with figure 2 As shown, the X-ray inspection apparatus 1 of this embodiment includes: an X-ray source 2 for irradiating the sample S with X-rays X1; The sample moving mechanism 3 moves the sample S to a specific direction Y1; the X-ray detection part 4 has a line sensor 41, which is arranged on the side opposite to the X-ray source 2 relative to the sample S, along the A plurality of pixels 4g are arranged in a direction perpendicular to the specific direction Y1, and the X-ray X1 transmitted through the sample S is detected by the pixel 4g; the image storage unit 6 stores the intensity of the X-ray detected by the pixel 4g; A correction unit 8 corrects the X-ray intensity stored in the image storage unit 6 ; and a defect detection unit 9 detects the presence or absence of a defect X ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com