Nonlinear flow modeling and compensating method for load port independent hydraulic system

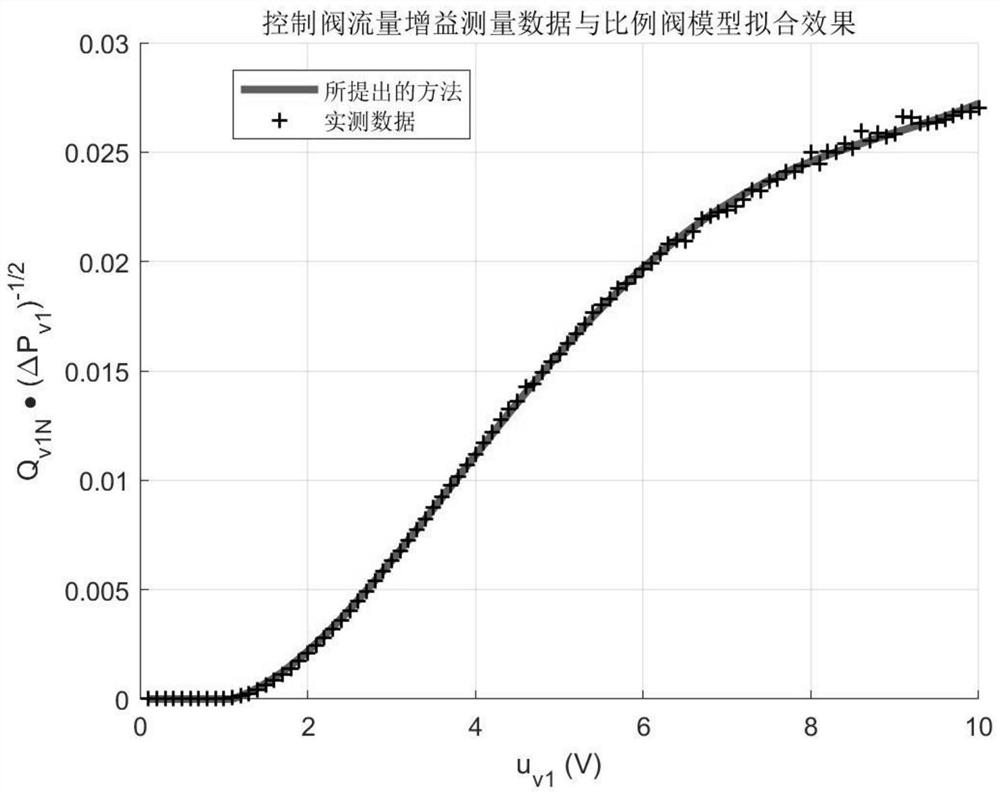

A hydraulic system and flow modeling technology, applied in the direction of flow control, non-electric variable control, control/regulation system, etc., can solve problems such as coil electromagnetic force nonlinearity, manufacturing precision leakage, etc., to achieve small calculation and reduce workload , quickly modeling the effects of uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

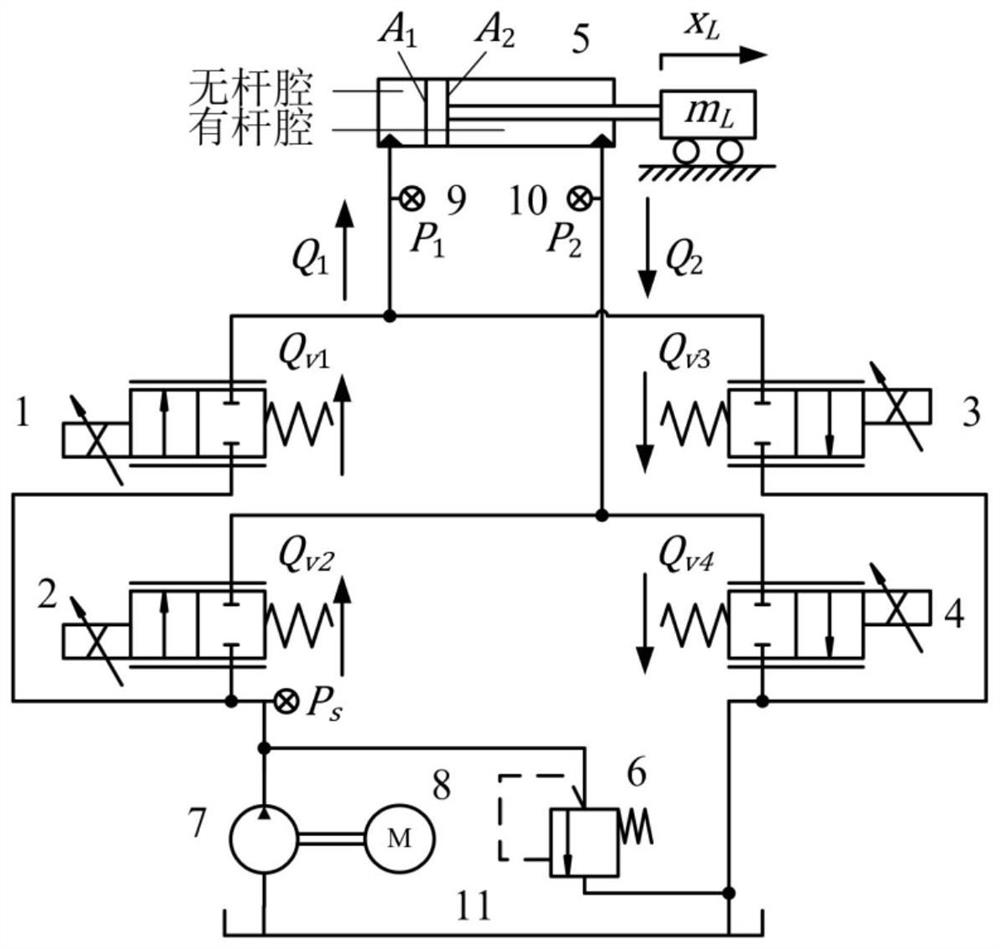

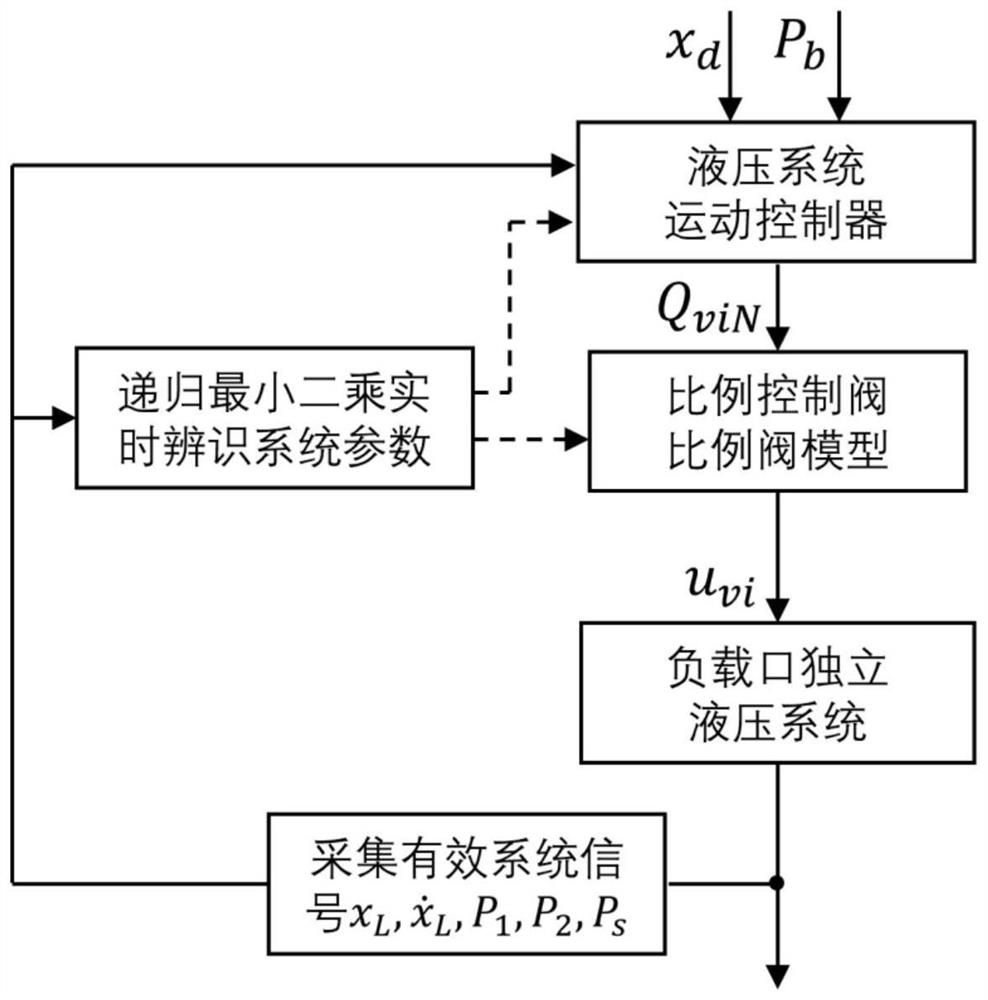

[0044] Such as figure 1 As shown, the load port independent hydraulic control system includes a system flow supply part mainly composed of a motor 8 and a hydraulic pump 7, mainly composed of a first proportional control valve 1, a third proportional control valve 3, a second proportional control valve 2, a fourth proportional control valve The flow control part composed of the proportional control valve 4, and the actuator part mainly composed of the hydraulic cylinder and the load; the hydraulic pump 7 is connected to the motor 8, and the operation of the hydraulic pump is controlled by the motor, and the four proportional control valves of the flow control part are connected in parallel Between the outlet of the hydraulic pump, the fuel tank and the hydraulic cylinder 5, the flow is controlled respectively, so that the flow in and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com