Flow battery stack

A technology for flow batteries and stacks, applied in the field of liquid guide plates, can solve the problems of increasing the thickness and weight of the stack, reducing the mass power density of the stack, and achieving the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

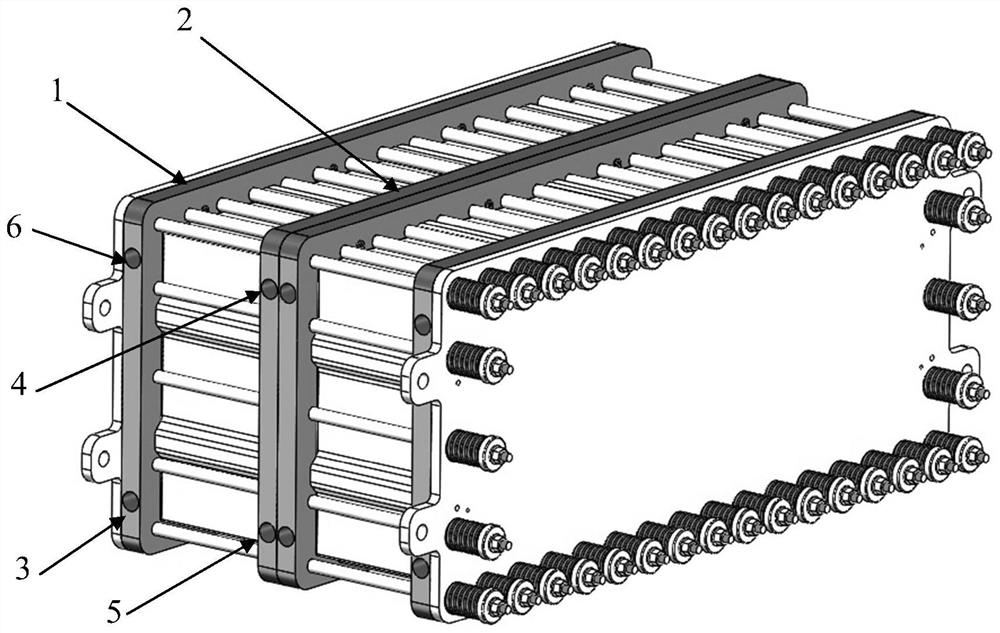

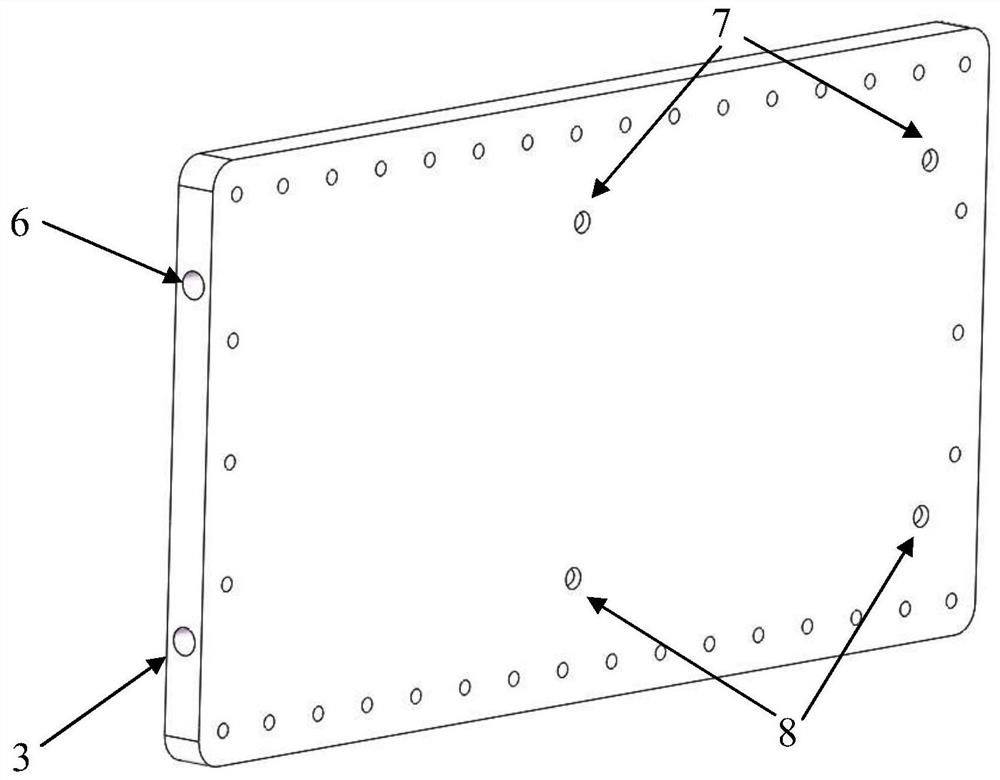

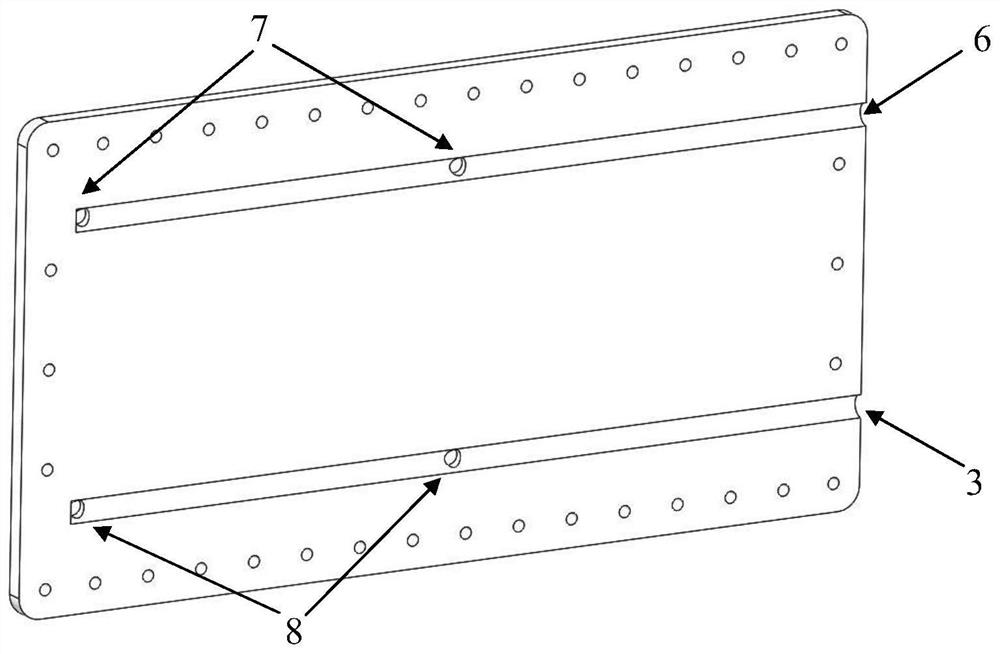

[0023] figure 1 For a conventional liquid flow battery high-power stack, the batteries of the entire stack are divided into two groups, and each group uses a liquid guide plate A ( figure 2 , image 3 ) and guide plate B ( Figure 4 , Figure 5 ) As the positive and negative electrolyte inflow and outflow organizational components. The positive electrode electrolyte flows into the positive electrode of each battery through the positive electrode electrolyte inlet of the 3 liquid guide plate A, and then flows out of the stack through the positive electrode electrolyte outlet of the 4 liquid guide plate B; the negative electrode electrolyte is electrolyzed through the negative electrode of the 5 liquid guide plate B The liquid inlet flows into the negative electrode of each battery, and then flows out of the stack through the negative electrode electrolyte outlet in 6 liquid guide plates A. Among them, the outlet of negative electrode electrolyte in 6 liquid guide plate A i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com