Water feeding and drainage equipment for aquaculture pond

A technology for aquaculture, water intake and drainage, applied in fish farming, application, animal husbandry, etc., can solve the problems of flushing into the vacuum pressure zone, accumulating into sludge, and reducing the area, so as to achieve great advocacy and benefit Effects of Structural Changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] as attached figure 1 to attach Image 6 Shown:

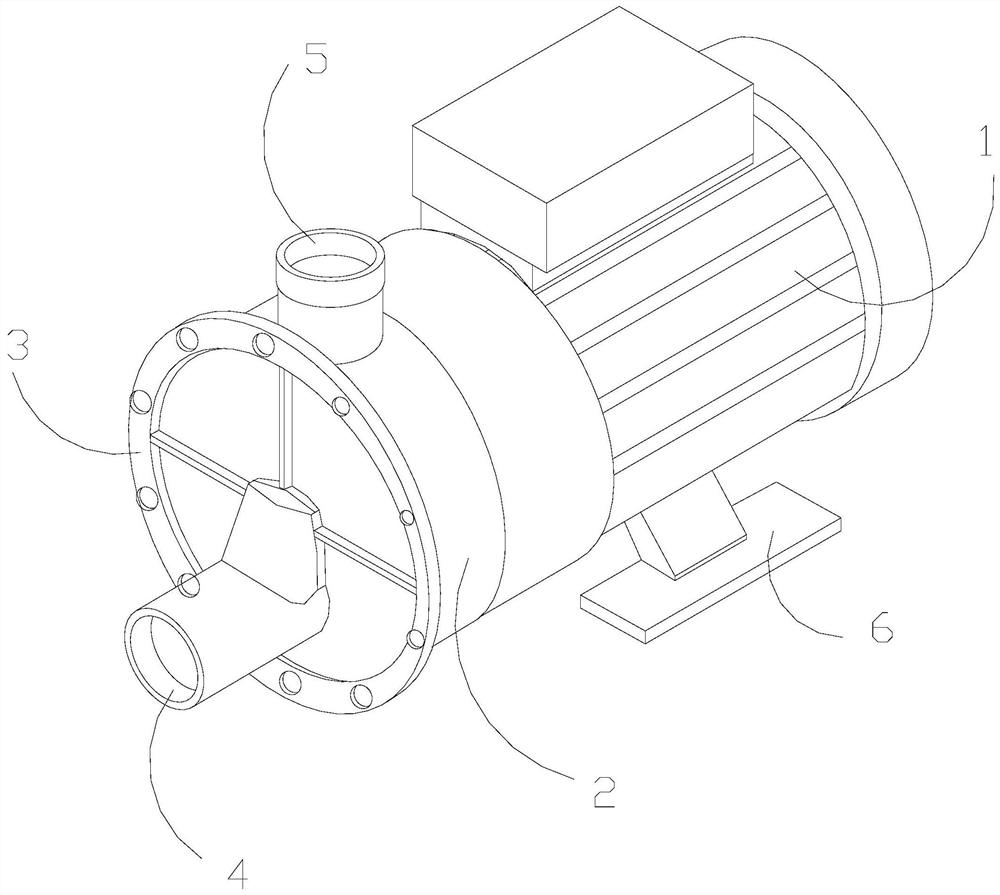

[0030] The invention provides a water inlet and drainage equipment for aquaculture ponds, the structure of which is provided with a rear drive machine 1, a front suction end 2, a card cover 3, a water inlet 4, a water outlet 5, and a support foot 6, and the support foot 6 is embedded and connected Below the rear drive machine 1, the front suction end 2 is installed at the front end of the rear drive machine 1 and cooperates with it. The card cover 3 is movably engaged with the front end of the front suction end 2. The water inlet 4 and the card cover 3 It is an integrated structure and communicates with each other, and the drain port 5 is connected to the top position of the front suction end 2 .

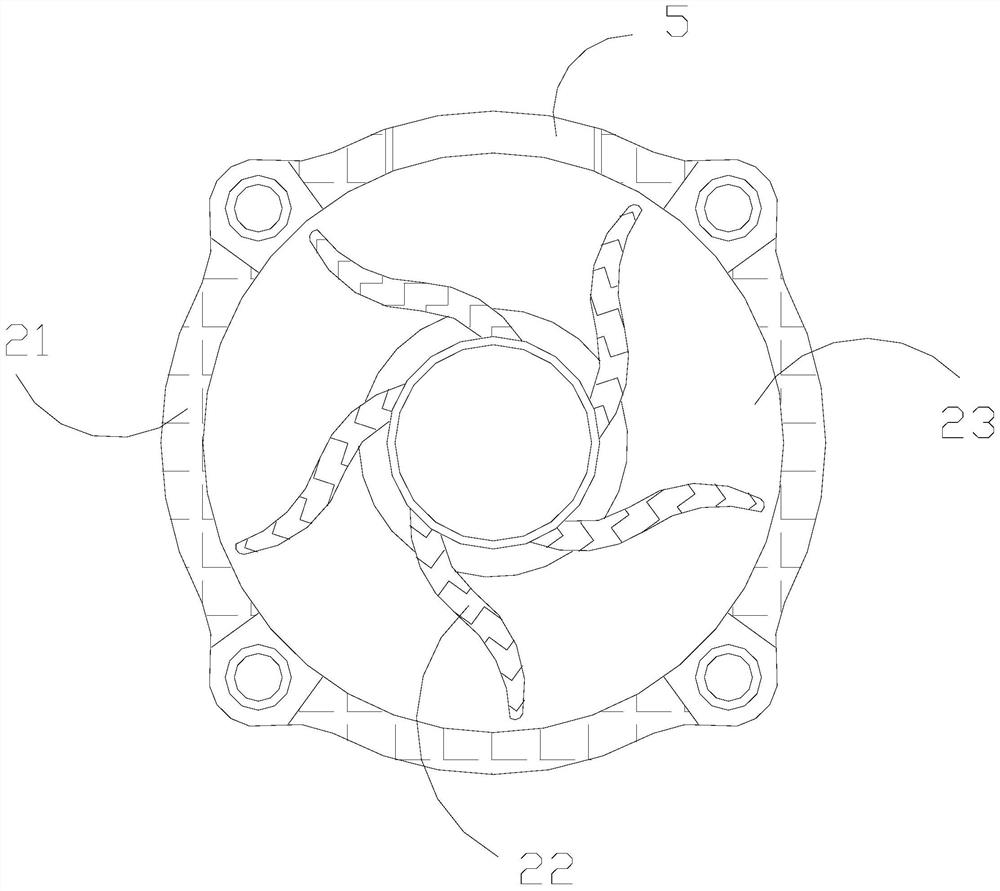

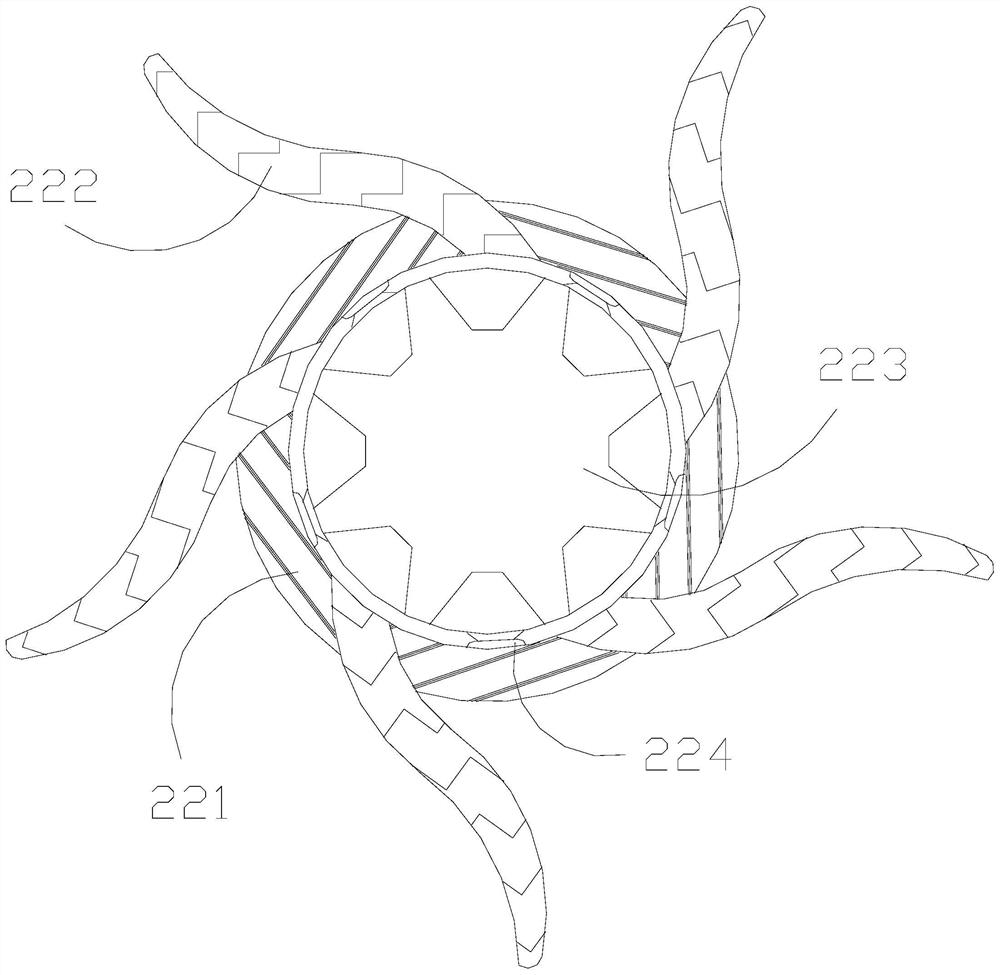

[0031] The front suction end 2 is provided with a frame body 21 , an impeller device 22 , and a water chamber 23 , the water chamber 23 is located at the inner side of the frame body 21 , and the impeller device 22 is embedde...

Embodiment 2

[0038] as attached Figure 7 to attach Figure 8 Shown:

[0039] Wherein, the ring wall block a2 is provided with a side groove rail a21, a front opening a22, an inner cavity a23, an air cushion a24, and an air port a25. The port a22 is located at the front end of the inner cavity a23, the inner cavity a23 and the ring wall block a2 are integrated and located inside, the air cushion a24 is embedded and connected to the rear end of the inner cavity a23, the air port a25 and the air cushion a24 are Integrated structure and through arrangement, the air cushion a24 is in the state of an arc lobe, has excellent elastic force, and can perform ups and downs. Deformation, the front opening a22 has a certain blocking effect on foreign objects, and at the same time generates a blowing force toward the outer end.

[0040] Wherein, the front port a22 is provided with a solid plate c1, an air blowing diameter c2, and a corner block c3, the solid plate c1 and the air blowing diameter c2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com