Novel tobacco powder removing device

A cleaning device, a new type of technology, is applied in the direction of removing smoke, tobacco, and manufacturing paper cigarettes, which can solve the problems of smoke sticking and not being able to suck away smoke, so as to prevent the smoke from being trapped and reduce the suction pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solutions and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

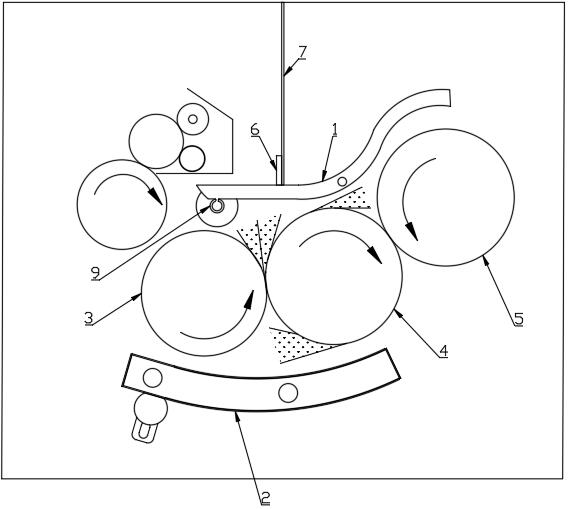

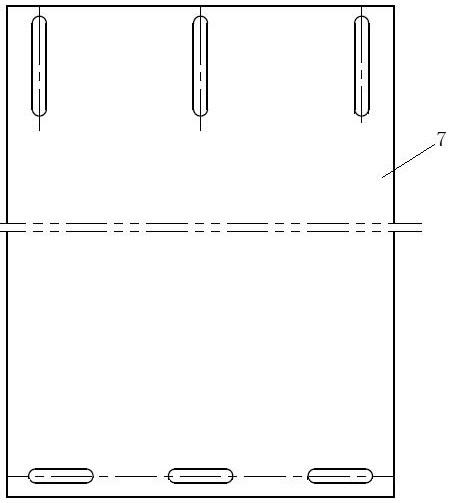

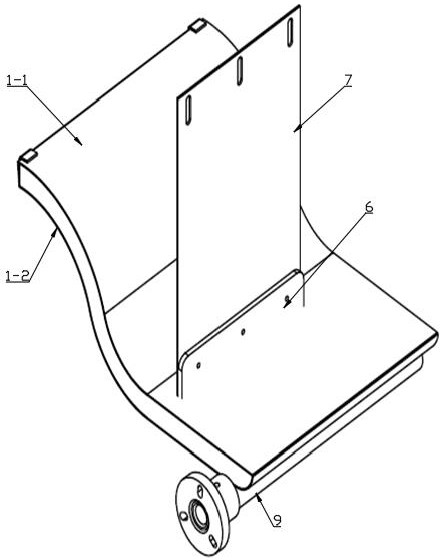

[0024] Such as Figure 1 to Figure 7 As shown, a new type of smoke removal device includes an upper foam suction assembly and a lower foam suction assembly. Installed under the closing drum and the converging drum, the upper foam suction assembly and the lower foam suction assembly are connected to the negative pressure main pipe of the suction hole of each drum of the cigarette machine through the negative pressure pipe, and the smoke entering the washboard is mainly the converging drum and the close drum It is generated when the cigarettes are handed over, and is brought into the washboard by the closing drum. The upper suction foam assembly is used to perform negative pressure s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap