A waste smoke extraction and transportation monitoring system and its control method

A monitoring system and conveying belt technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as unfavorable waste smoke quality, increase operator labor load, analysis, etc., to reduce operating time and reduce maintenance Time, the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

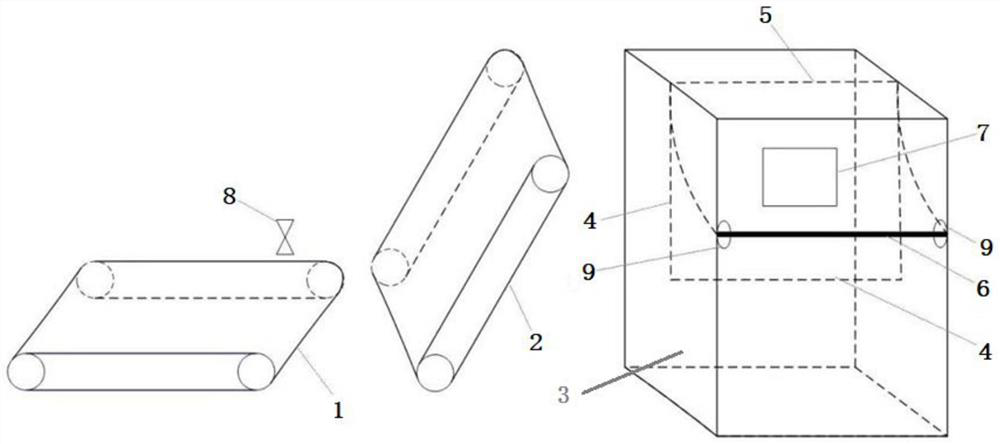

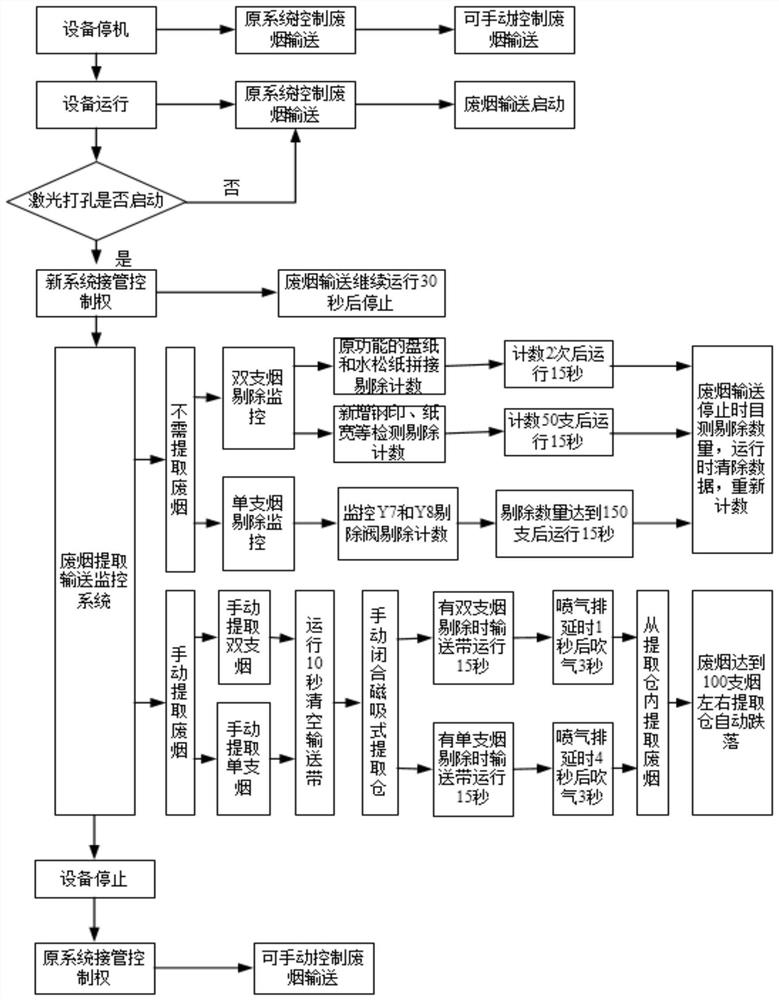

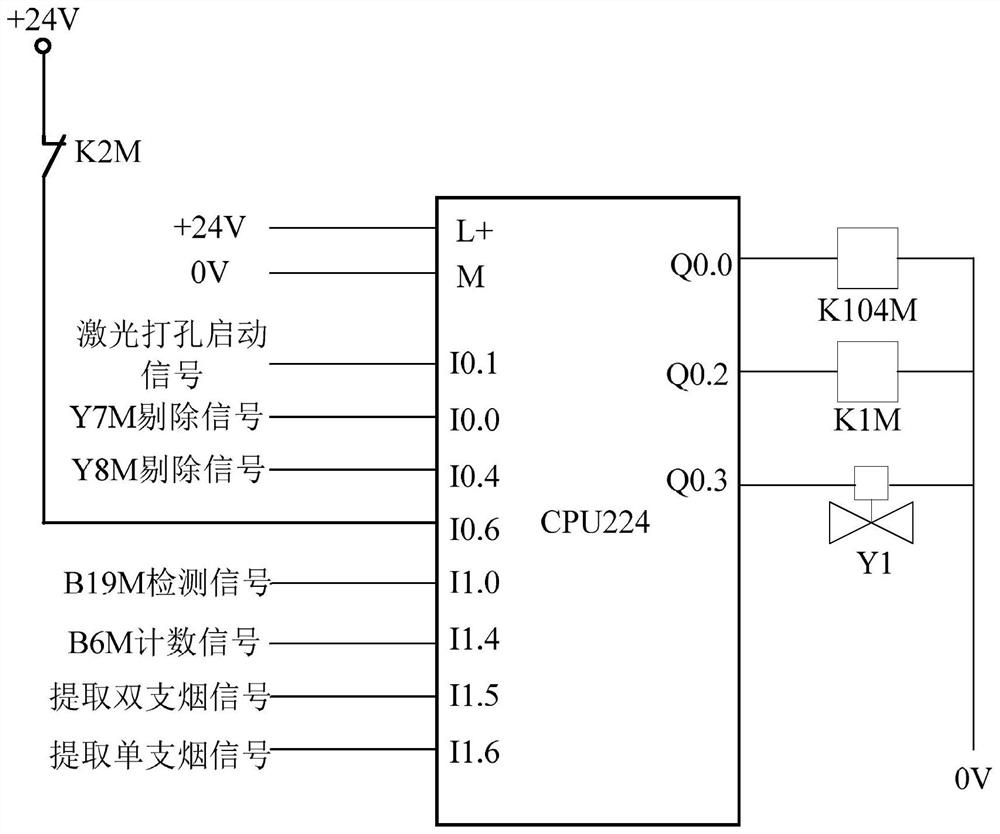

[0031] Such as Figure 1 to Figure 5 As shown, the present invention provides a waste smoke extraction and transportation monitoring system, including a data processing module, a human-computer interaction interface, a relay K1M, a relay K2M, a motor control contactor K104M, a solenoid valve Y1, an air jet exhaust A8, and a waste smoke conveying belt 1 and waste collection box 3;

[0032] The human-computer interaction interface includes a touch display screen and a human-computer interaction controller connected to the touch display screen. The touch display screen is provided with a touch button for extracting double cigarette signals and a touch button for extracting single cigarette signal. Human-computer interaction The controller can be a PLC controller; when the touch button is pressed to extract the signal of double cigarettes, the PLC controller sends the signal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com