Gas-liquid or liquid-liquid mixed ultramicro bubble generation device

A technology of ultra-micro-bubble and generating device, applied in gas/vapor and liquid mixing, mixer, mixing method, etc., can solve the problems of low concentration of ultra-micro bubbles, large energy loss, and low overall number of turns, etc. The effect of liquid mixing efficiency, increasing contact time, and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

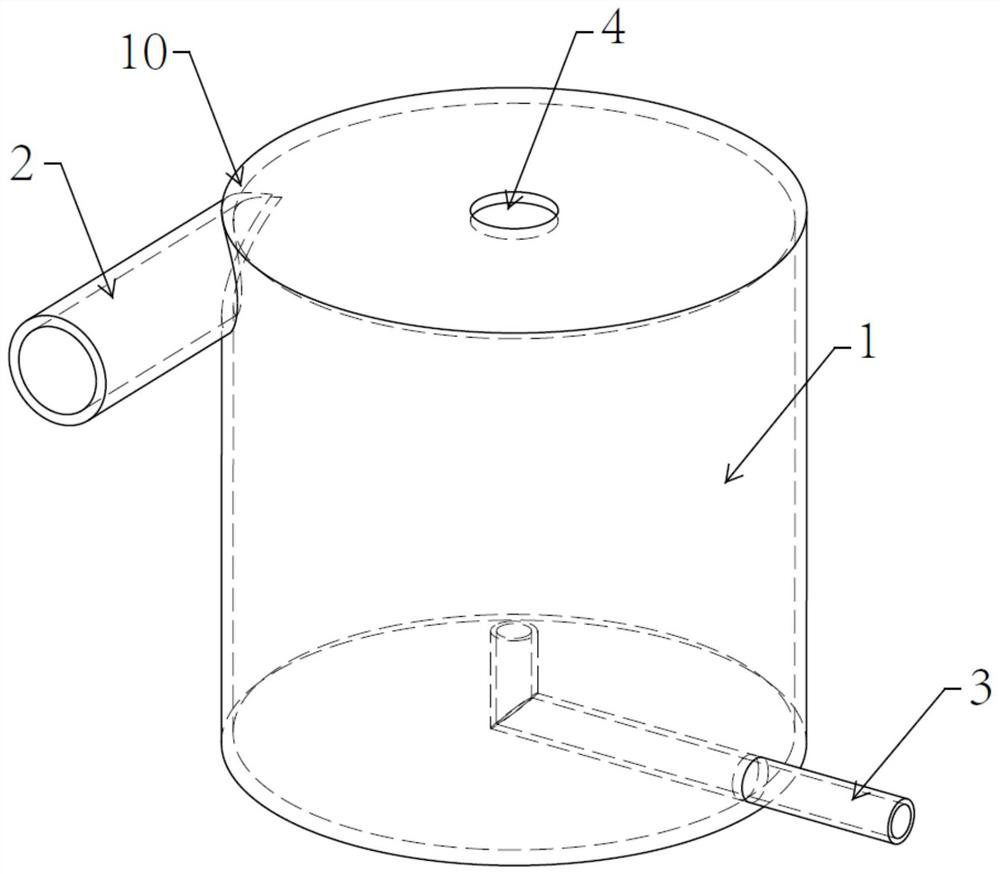

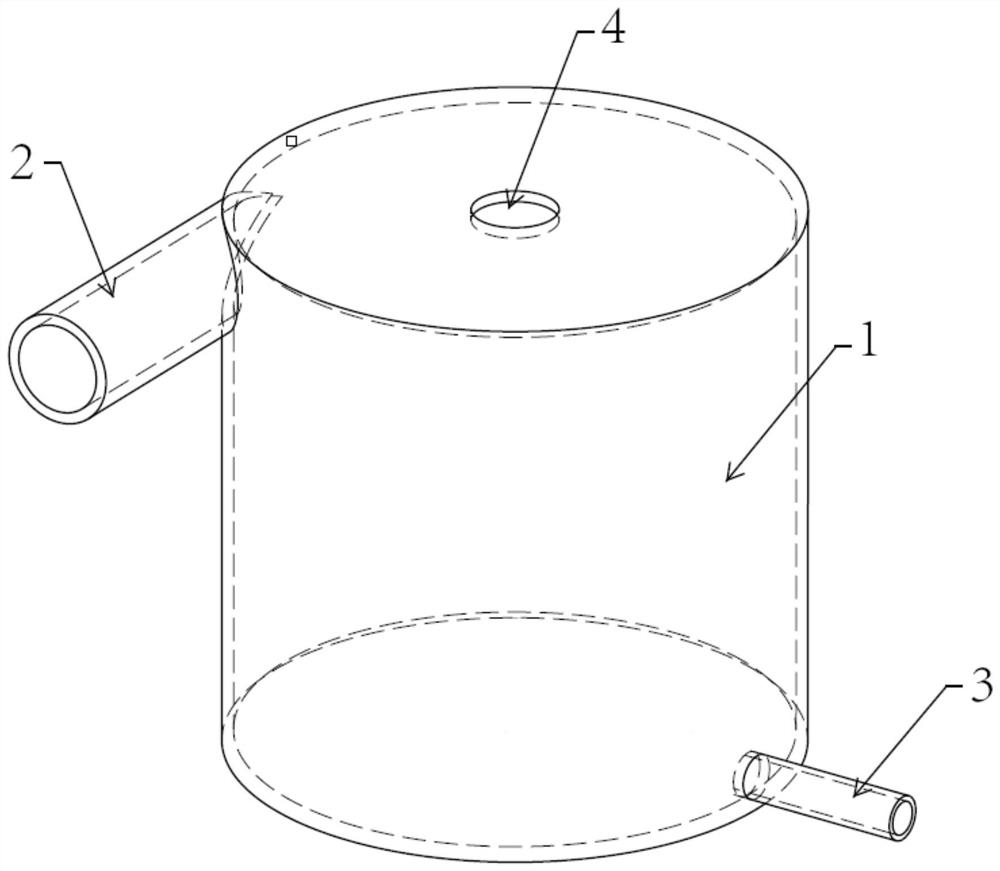

[0049] see Figure 1-2 , 4-9, the present invention provides a kind of technical scheme:

[0050] A gas-liquid or liquid-liquid mixed ultrafine bubble generating device, comprising:

[0051]The cavity 1 has an internal flow cavity 7 built in the cavity, and an external flow cavity 6 is formed between the internal flow cavity wall 5 of the internal flow cavity 7 and the cavity body 1;

[0052] The diversion port 10 is used to input the liquid I into the outer flow chamber 6;

[0053] The gas-liquid inlet 3 is used to input gas or liquid II into the inner flow chamber 7;

[0054] The liquid I enters the outer flow chamber 6 for a spiral acceleration, and then enters the inner flow chamber 7, and then continues to accelerate for a second time to generate negative pressure, and the gas or liquid II entering the gas-liquid inlet 3 is sucked and fully mixed and cut. , forming a gas-liquid;

[0055] The nozzle 4 is located in the center of the cavity 1 and is used for spraying ga...

Embodiment 2

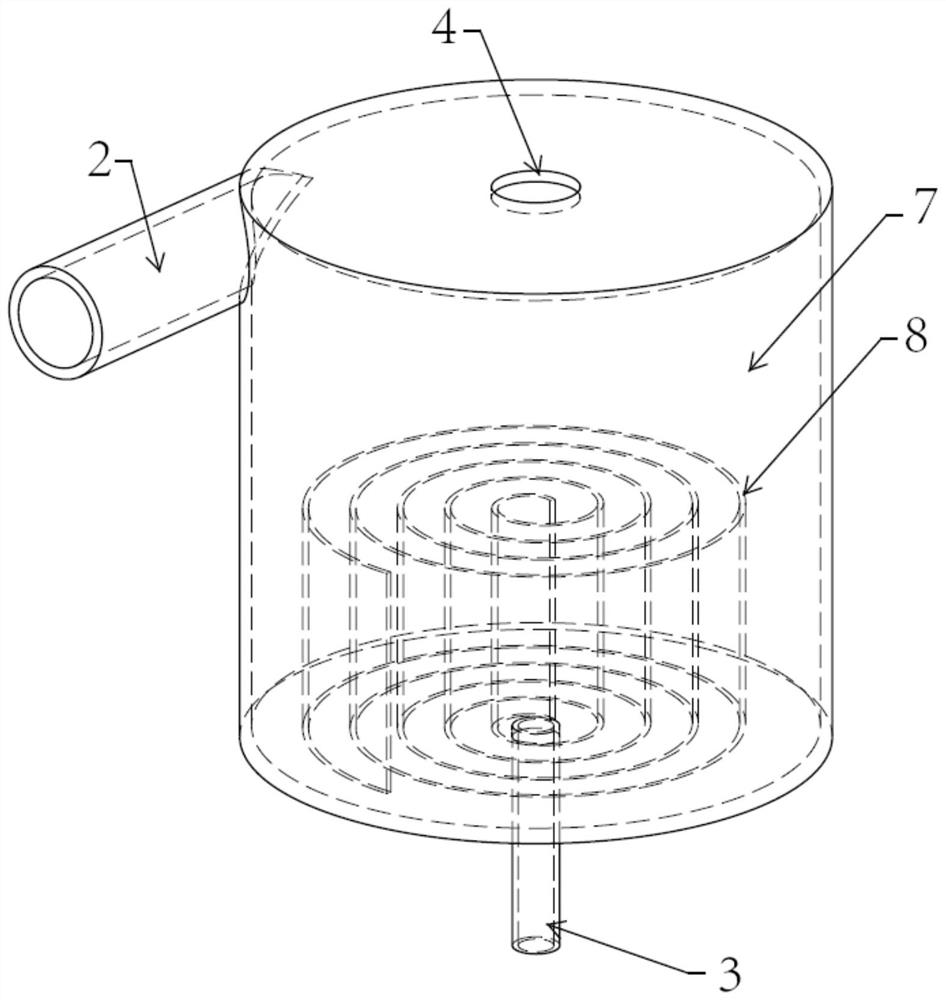

[0073] see image 3 , the present invention provides a kind of technical scheme, is basically the same as embodiment 1, and difference is:

[0074] A gas-liquid or liquid-liquid mixed ultrafine bubble generating device, comprising:

[0075] Chamber 1, including inner flow chamber 7, is used to accelerate, mix and cut liquid I and gas or liquid II, and form gas-liquid;

[0076] The diversion port 10 is used to input the liquid I into the cavity 1;

[0077] Gas-liquid inlet 3, used to input gas or liquid II into cavity 1;

[0078] The helical track 8 is placed in the cavity 1, and is used for spiral acceleration of liquid I and gas or liquid II; fully mixed.

[0079] The nozzle 4 is located in the center of the cavity 1 and is used for spraying gas and liquid.

[0080] In this embodiment, there is only one cavity, that is, the inner flow cavity 7 .

[0081] The technical principle of embodiment 2 is:

[0082] The liquid I (usually water) is connected to the diversion outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com