Polishing and code spraying integrated equipment and using method thereof

An equipment and coding technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of reducing the clarity of product coding, reducing the recognition rate of two-dimensional code, reducing equipment work efficiency, etc., to achieve convenient Coding work again, improve enterprise production efficiency, and improve the effect of coding clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

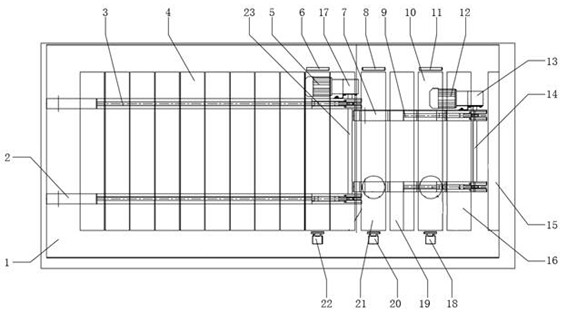

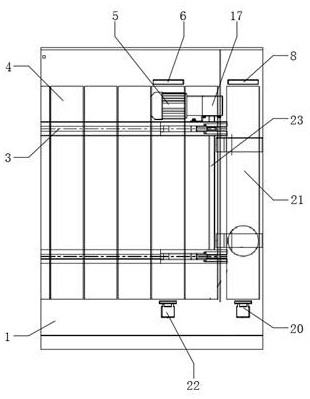

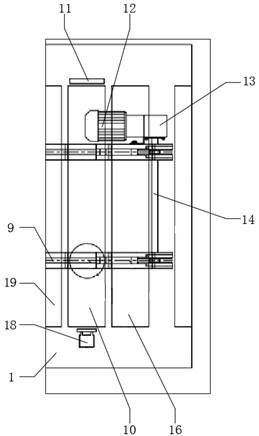

[0033] see Figure 1-4 , the present invention provides a technical solution: an integrated grinding and coding equipment, including a base 1, a first plate 4 is fixedly connected to the front surface of the base 1, and a first servo motor 5 is installed on the front surface of the first plate 4 , the output end of the first servo motor 5 is welded with a second frequency converter 17, the output end of the second frequency converter 17 is welded with a second rotating rod 23, and the outer wall of the second rotating rod 23 is connected with the first transmission belt 3, the second The inside of a transmission belt 3 is fixedly connected with the first fixed block 2, and the front surface of the base 1 is welded symmetrically with two support plates 24, and the front surfaces of the two support plates 24 are respectively welded with the fifth plate body 21 and the fourth plate body 19 , the second board 10 and the third board 16, the front surface of the base 1 is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com