Solid raw material crushing device and method thereof

A raw material pulverization and equipment technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of poor pulverization effect of solid raw materials, splashing of debris, insufficient and thorough pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

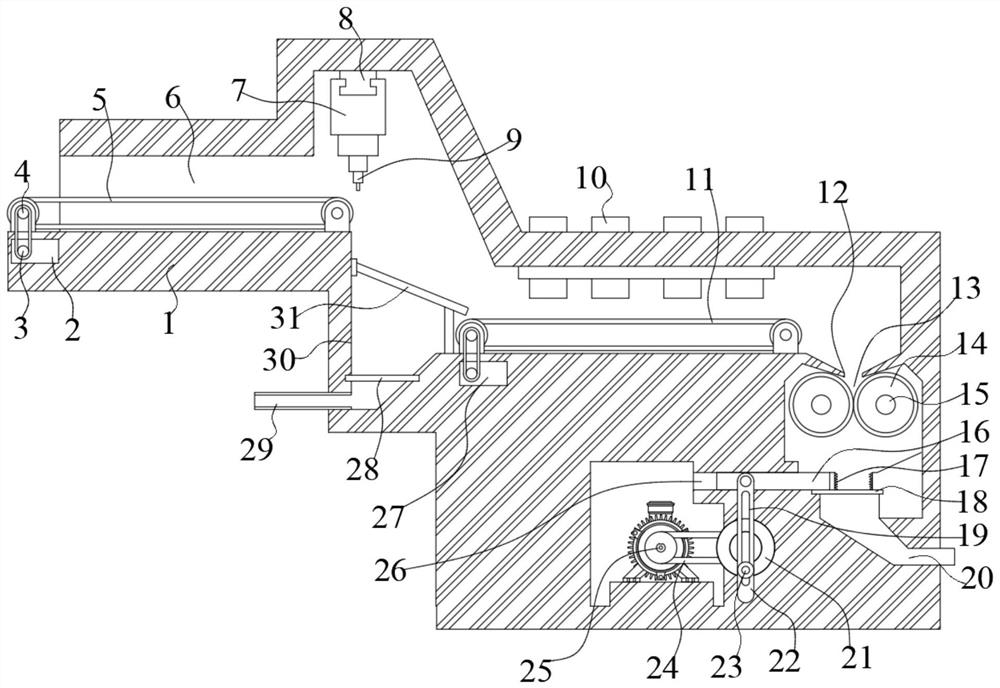

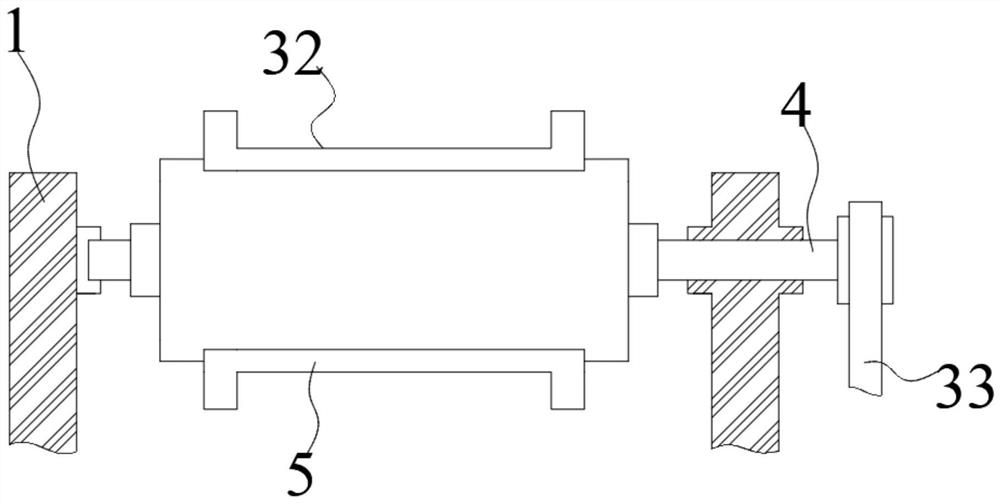

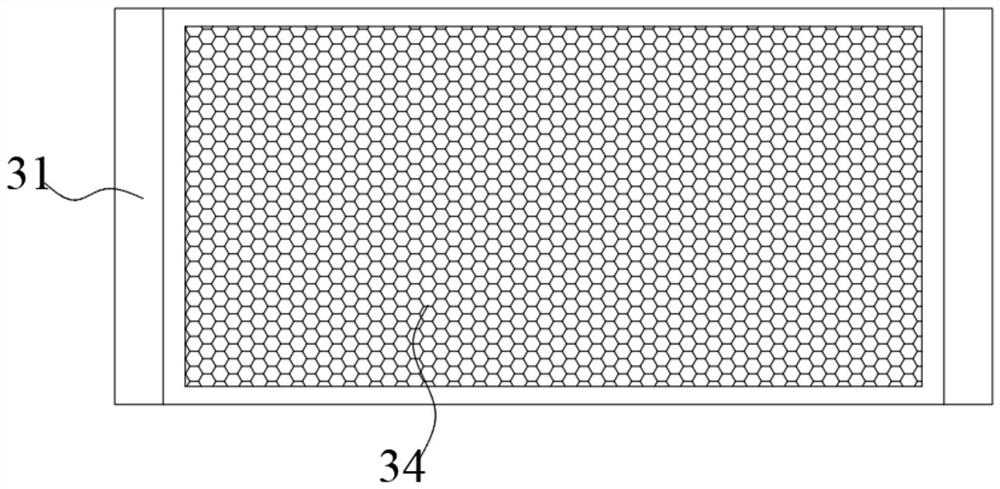

[0024] Embodiment one, by Figure 1-4Given, the present invention is a kind of solid raw material crushing equipment and method thereof, including a body 1, a cutting groove 6 is opened on the left outer wall of the body 1, and a support shaft 4 is rotatably connected to the inner wall of the bottom surface of the cutting groove 6, and the support One end of the shaft 4 is slidably connected to the inner wall of the belt A33, and the inner wall of the belt A33 is slidably connected to one end of the rotating shaft A3, and the other end of the rotating shaft A3 is rotatably connected to the inner wall of the motor A2, and the upper surface of the cutting groove 6 is provided There is a slide rail 8, and the outer wall of the bottom surface of the slide rail 8 is slidably connected with an electric slider 7, the outer wall of the bottom surface of the electric slider 7 is fixedly connected with a water jet cutting machine 9, and the inner wall of the bottom surface of the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com