Deviation correcting device applied to large plastic pipe production

A technology of plastic pipes and deviation correction devices, which is applied in the field of deviation correction devices, can solve the problems that large-scale pipes cannot be corrected, and achieve the effects of improving convenience, increasing safety, and saving workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Attached below Figure 1-7 The present invention is described in detail below.

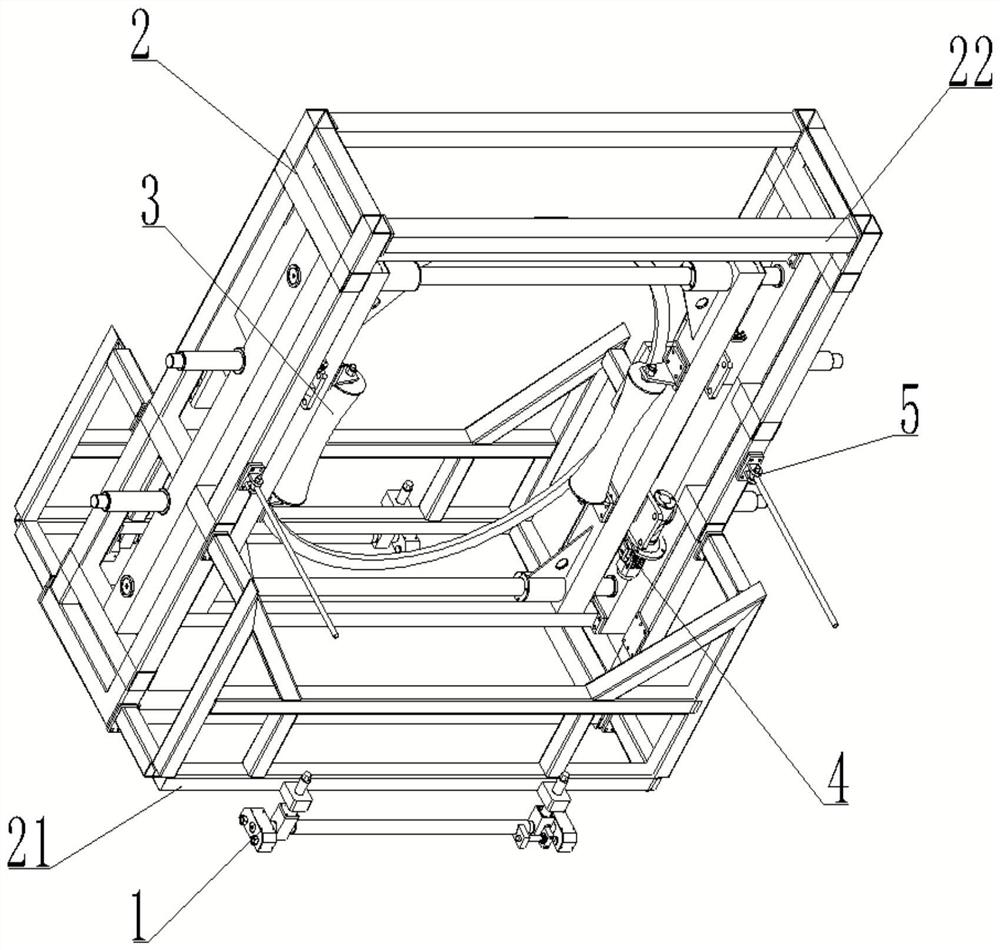

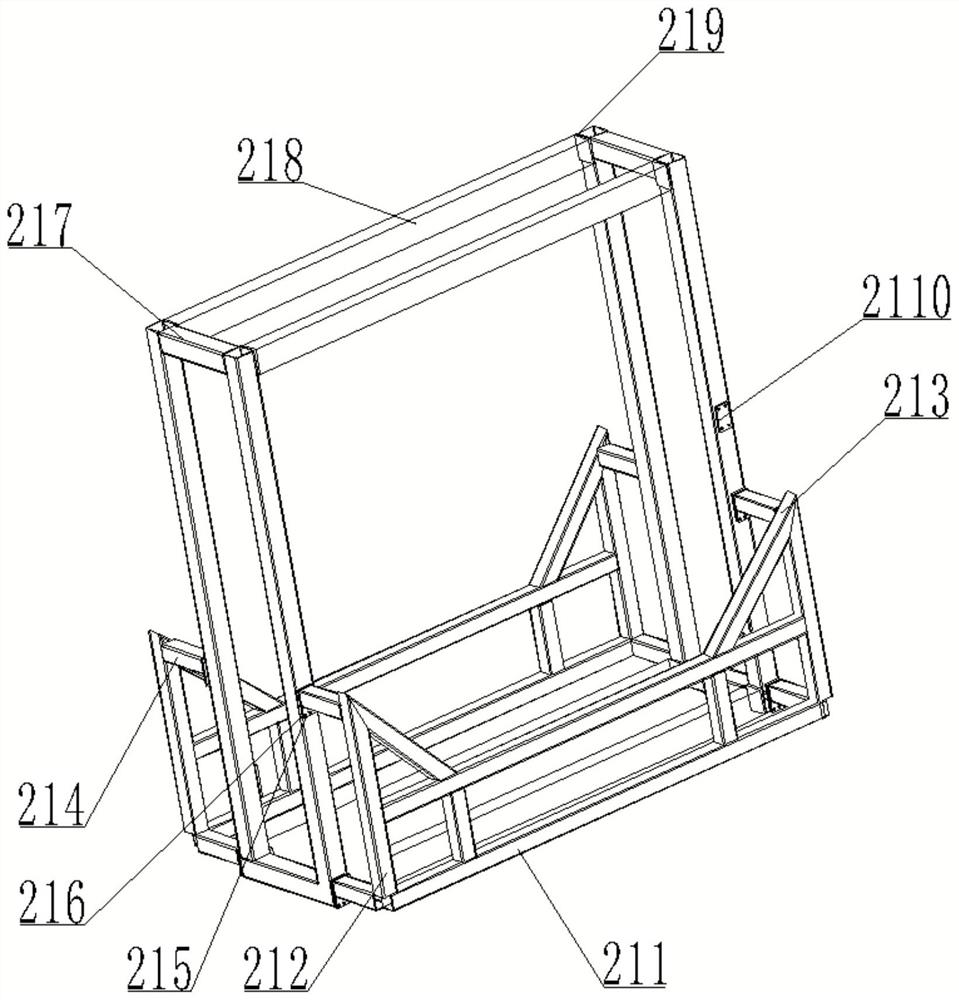

[0026] Such as Figure 1-7 As shown, the present invention includes a caster assembly 1, a frame assembly 2, a pressure roller assembly 3, a lift assembly 4 and a connecting rod assembly 5, the caster assembly 1 is arranged below the frame assembly 2, and the pressure roller assembly 3 is arranged on the frame Inside the assembly 2 , the elevator assembly 4 is arranged on both sides of the pressure roller assembly 3 , and the connecting rod assembly 5 is arranged at the front end of the frame assembly 2 .

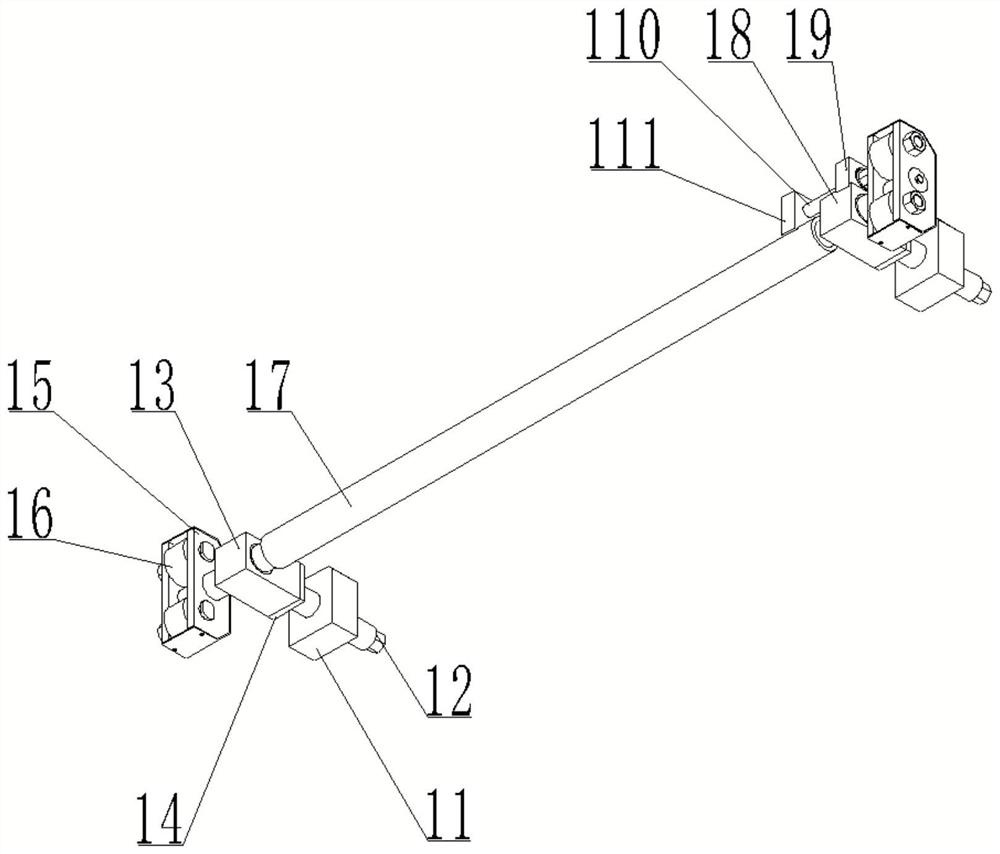

[0027] There are two sets of caster assembly, each set of caster assembly 1 is equipped with anchor block 11, anchor screw 12, bearing seat A13, bearing seat cover 14, cover 15, roller 16, guide rail 17, bearing seat B18, Block A19, block shaft 110 and block B111, the anchor block 11 is provided with two, and each anchor block 11 is fixed on the front of the frame assembly 2 by welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com