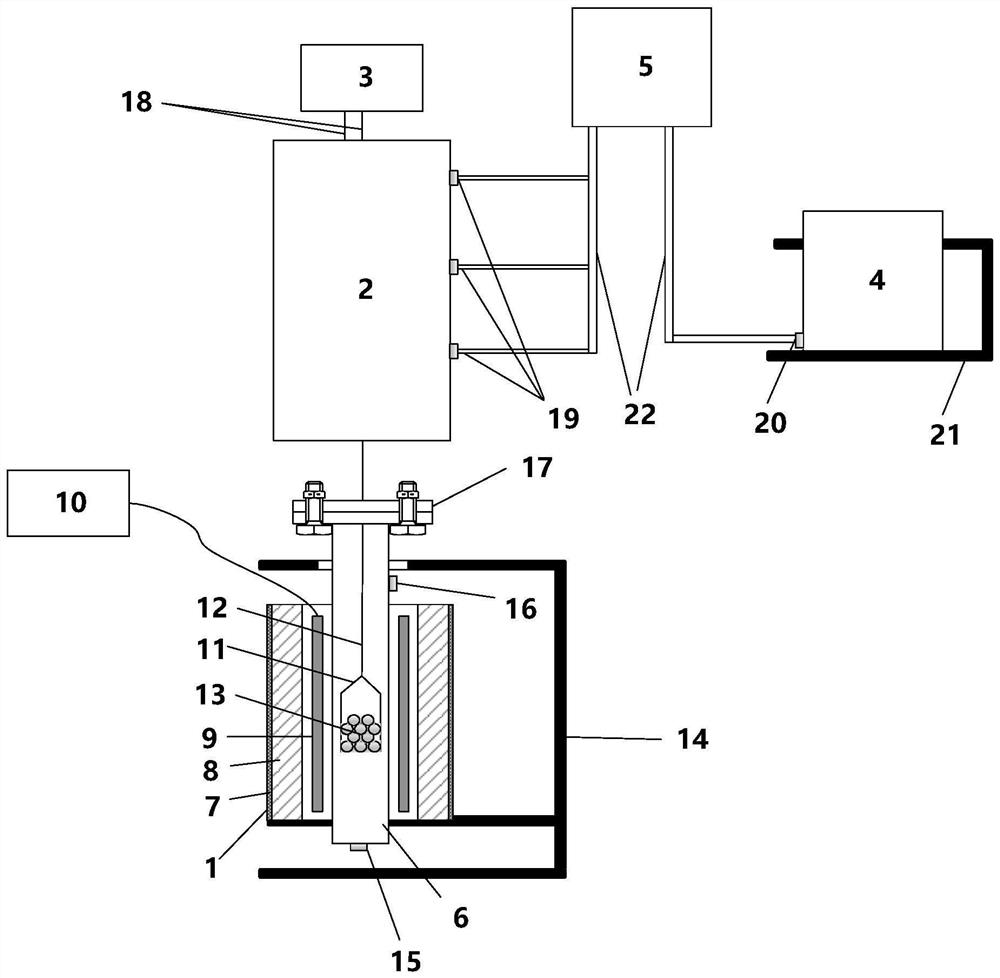

Gas-based reduction simulation device and gas-based reduction simulation method

A simulation device and simulation method technology, applied in fluidized bed furnaces and other directions, can solve problems such as low accuracy of experimental results, and achieve the effects of ensuring setting stability, facilitating connection, and reducing secondary oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

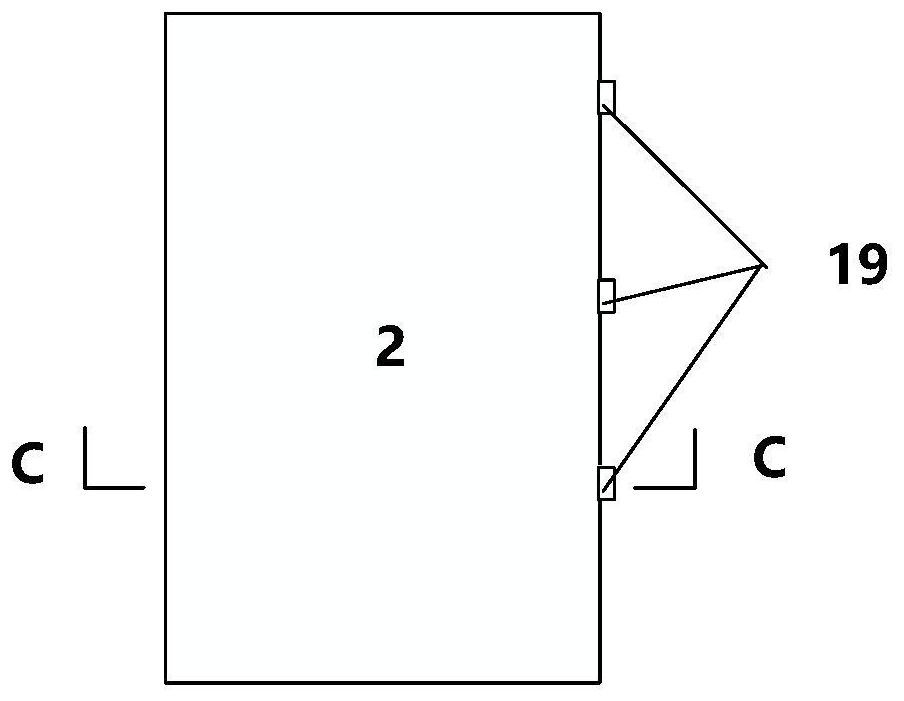

Method used

Image

Examples

Embodiment 1

[0096] Step A: Set the temperature of the furnace tube, the reduction temperature is 1200°C, the temperature rise rate in the furnace tube is 10°C / min, and nitrogen is introduced into the furnace tube through the reduction air inlet, and the nitrogen flow rate is 1L / min;

[0097] Step B: When the temperature in the furnace tube reaches 1200°C, lower the upper flange with one end of the protector hanging wire together with the loading basket lifted by the lower tube loading basket hanging wire through the hoisting device, and place the loading The basket is put into the furnace tube, the upper flange and the lower flange are aligned and fixed with bolts;

[0098] Step C: Set the reduction air inlet to feed carbon monoxide into the furnace tube, the gas flow rate is 1L / min, the pressure inside the furnace tube is 0.005Mpa, and the reduction time is 20min;

[0099] Step D: After the experiment is completed, change the gas from the reduction inlet to the furnace tube to nitrogen, ...

Embodiment 2

[0104] Step A: Lower the upper flange with one end of the protector hanging wire together with the charging basket hoisted by the lower tube loading basket hanging wire through the hoisting device, and put the charging basket into the furnace tube, the upper flange Align with the lower flange and fix with bolts;

[0105] Step B: Set the temperature of the furnace tube, the reduction temperature is 1200°C, the temperature rise rate in the furnace tube is 10°C / min, and nitrogen is introduced into the furnace tube through the reduction air inlet, and the nitrogen flow rate is 1L / min;

[0106] Step C: When the temperature in the furnace tube reaches 1200°C, set the reduction air inlet to feed hydrogen into the furnace tube, the gas flow rate is 1L / min, the pressure in the furnace tube is 0.01Mpa, and the reduction time is 30min;

[0107] Step D: After the experiment is completed, change the gas from the reduction inlet to the furnace tube to nitrogen, and then open the bolts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com