A kind of cooling structure of turbine blade separation, lateral rotation and re-convergence

A turbine blade and cooling structure technology, applied in the direction of blade support components, machines/engines, mechanical equipment, etc., can solve the problems of low cooling effect, short flow distance, small heat exchange area of cold air and trailing edge, etc., to achieve improved Cooling effect, effect of increased heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

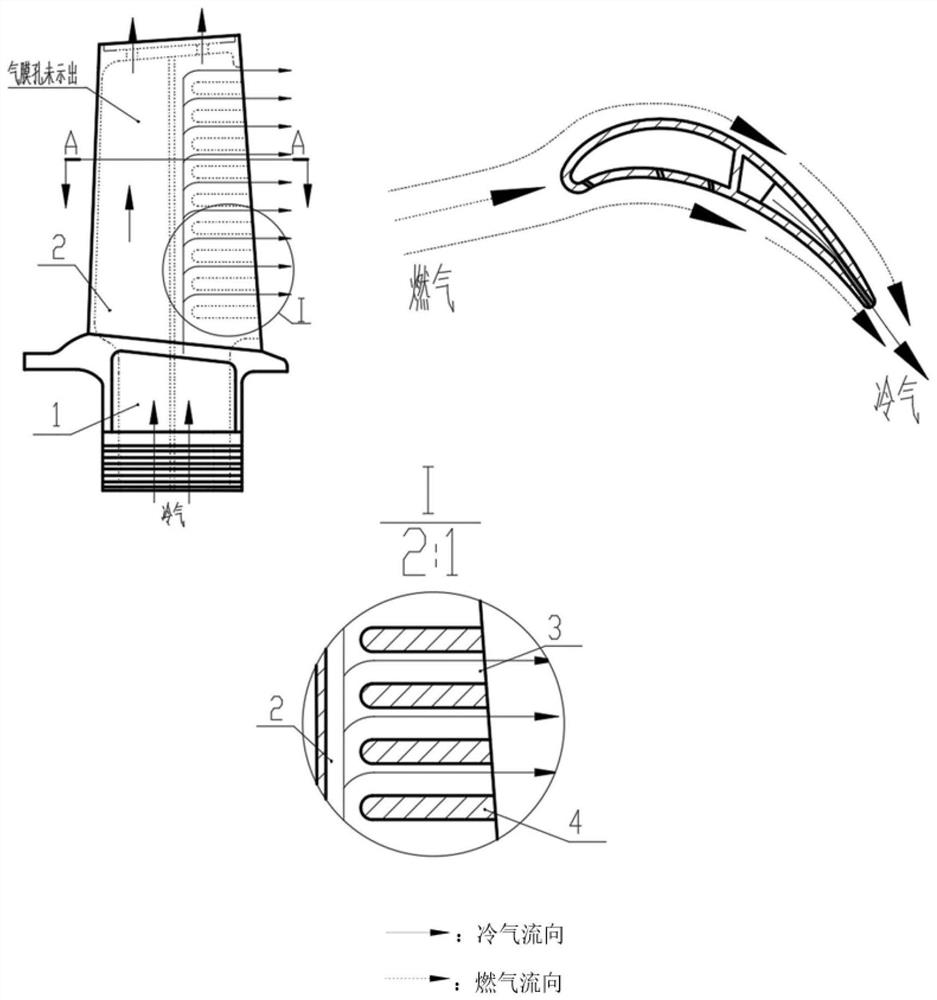

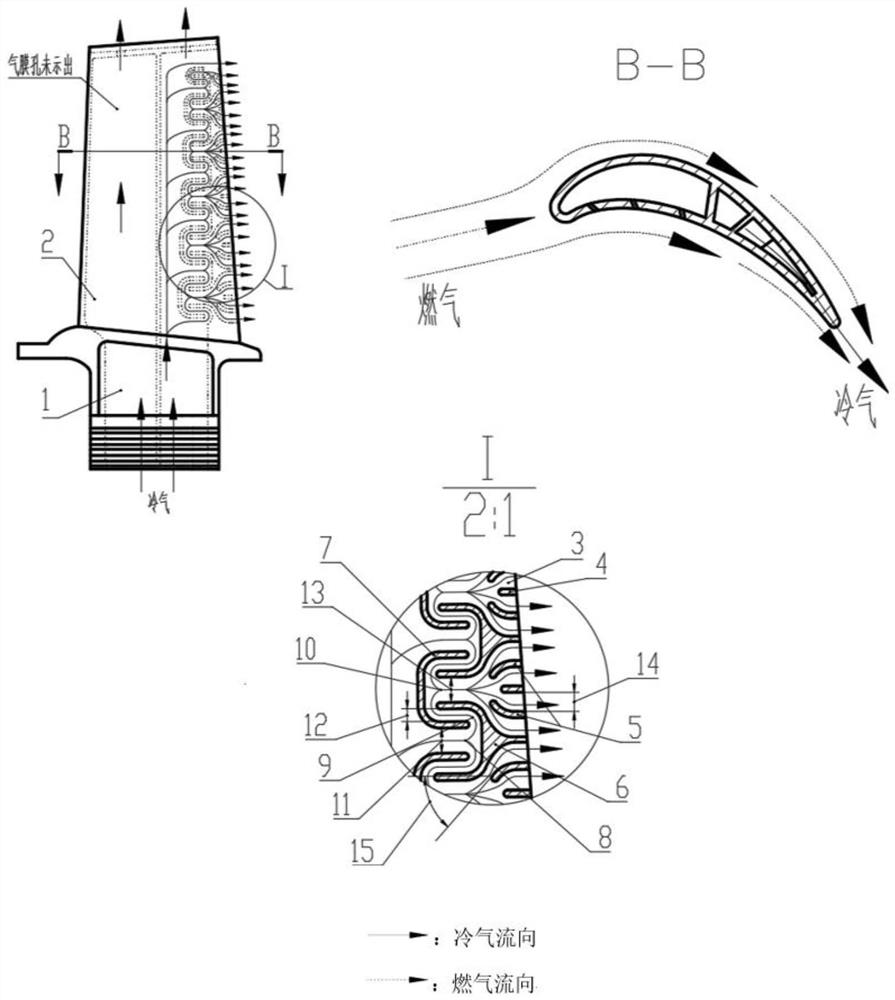

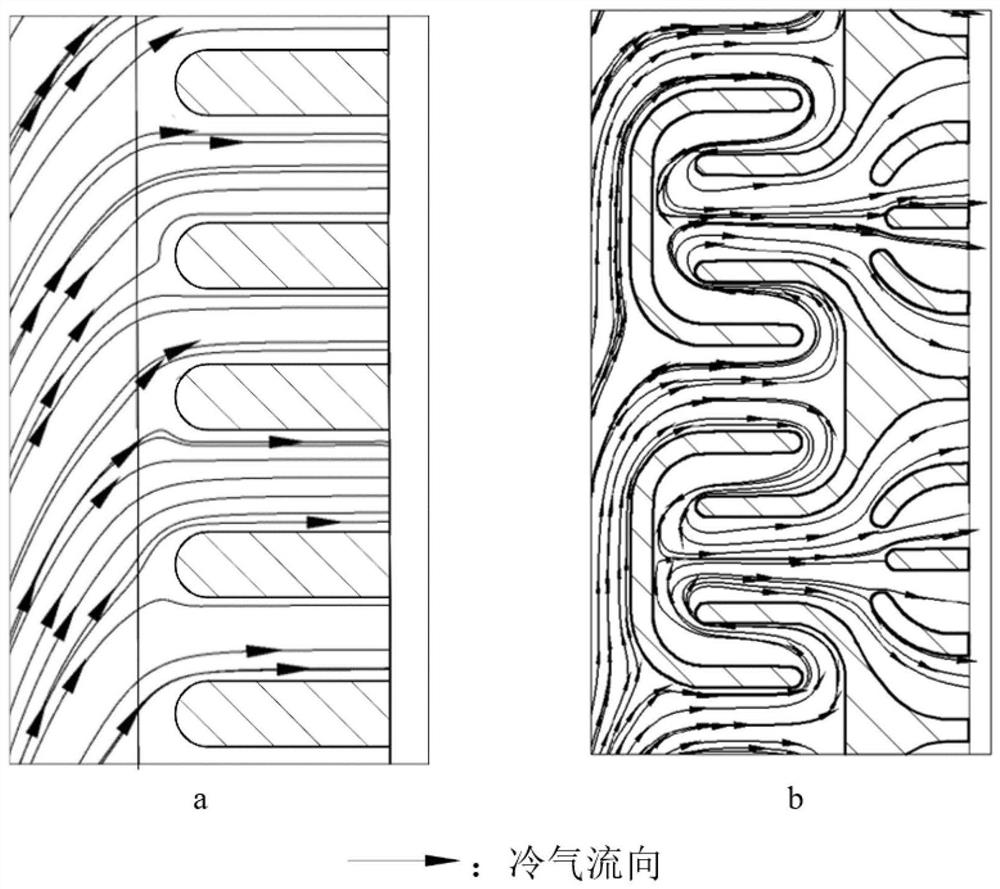

[0025] A type of cooling structure of turbine blade separation, lateral rotation and re-convergence is mainly composed of a herringbone-shaped partition rib 6, a C-shaped partition rib 7, a J-shaped partition rib 5, and a trailing edge split-slot straight rib 4. figure 2 shown.

[0026] The hollow turbine blade 1 is provided with an inner cavity cold air channel 2 for the low temperature cooling gas to flow inside the blade to cool the blade. The trailing edge of the blade is evenly distributed with herringbone-shaped partition ribs 6 and C-shaped partition ribs 7 along the radial direction. A cold air separation channel 8 is formed between two adjacent C-shaped ribs and its width is D 1 = 2.4mm, the cold air flows downstream in this channel and is separated into two airflows that flow to the blade root and the blade tip respectively, and the first 180° rotation is performed in the two cold air rotation channels respectively, and the reverse flow in the direction of the inco...

Embodiment 2

[0029] The cooling structure of separation, lateral rotation and re-convergence provided by the present invention can be used not only on the trailing edge of the blade, but also on the leading edge of the blade, such as Figure 4 shown.

[0030] The hollow turbine blade 1 is evenly distributed with C-shaped ribs 7 and reversed C-shaped ribs 17 on the leading edge along the radial direction. .

[0031] A cold air separation channel 8 is formed between two adjacent front edge reverse C-shaped ribs 17 and its width is D 1 =2.4mm, the cold air flows downstream in this channel and is separated into two airflows that flow to the blade root and the blade tip respectively, and the first 180° rotation is performed in the two cold air rotation channels respectively, and the reverse flow in the direction of the incoming flow . Except for the two at the ends, two cold air circulation channels 9 are formed between each front edge reverse C-shaped rib 17 and two adjacent C-shaped ribs 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com