Floating seal assembly

A floating seal and assembly technology, applied in the direction of engine seals, engine components, transmission parts, etc., can solve the problems of reduced compression force, exposure of crawler to soil, sand or silt, other pollutants, and reduced surface pressure. The effect of improving lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

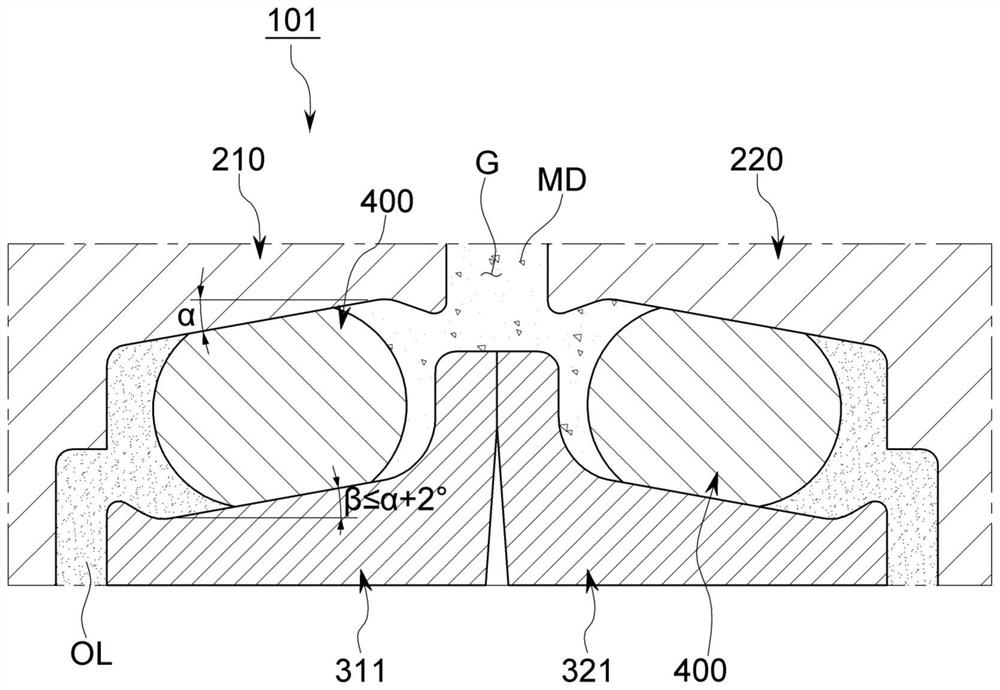

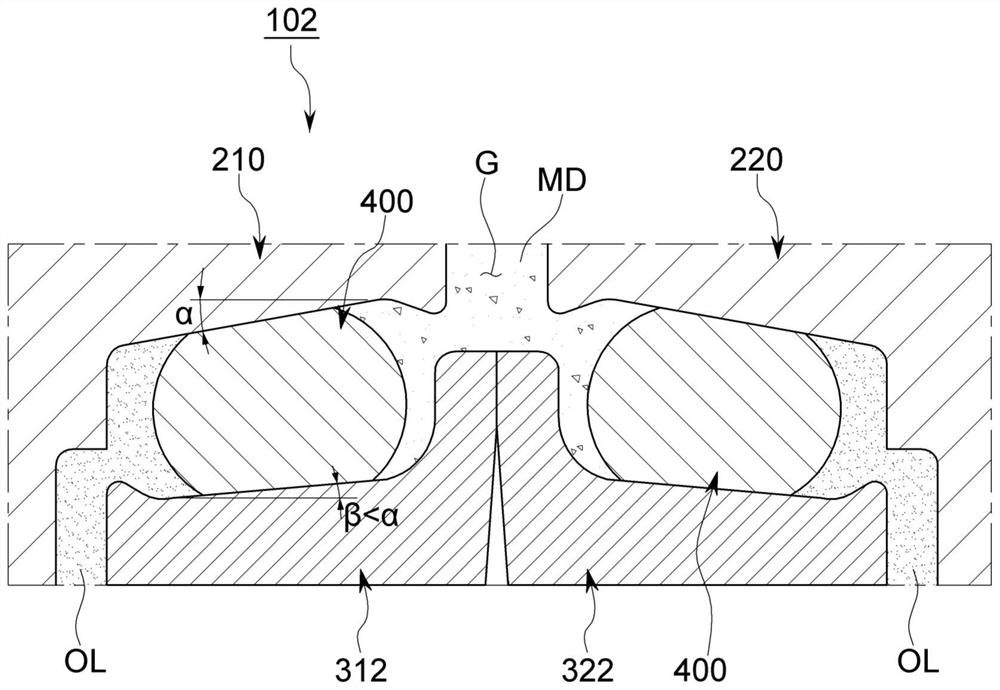

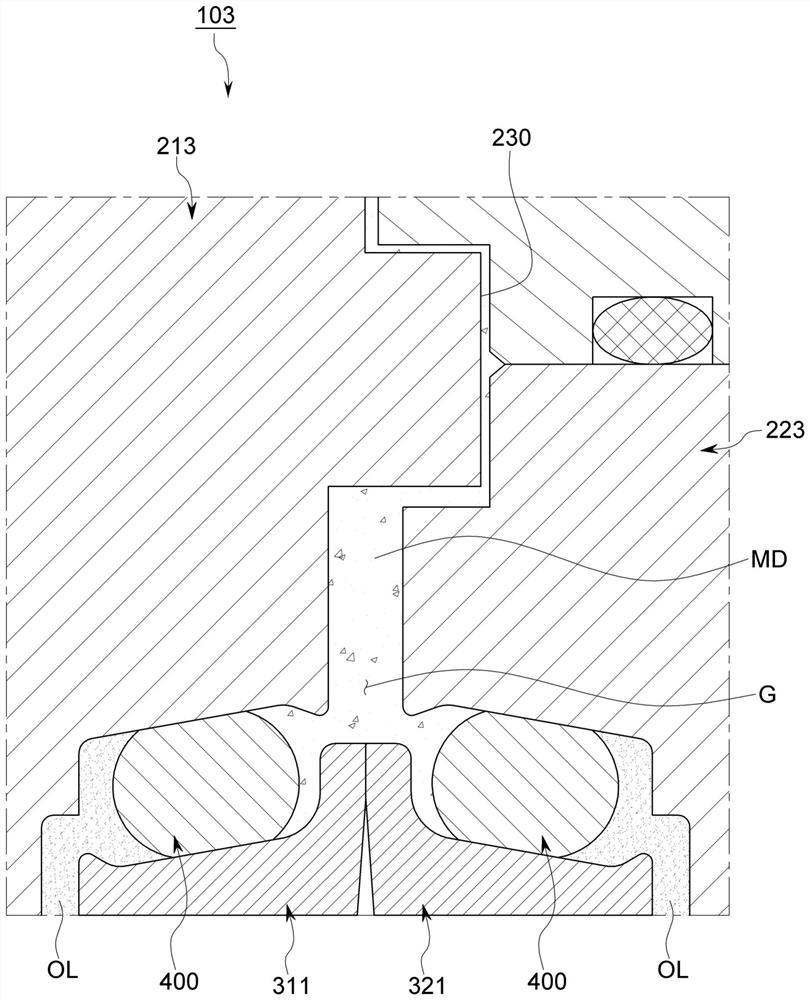

[0018] Embodiments of the present invention will be described below with reference to the accompanying drawings so that those skilled in the art to which the present invention pertains can easily implement. The present invention can be implemented in various forms and is not limited to the embodiments described here.

[0019] In addition, in several embodiments, the same code|symbol is used for the component which has the same structure, and the 1st embodiment is representatively demonstrated, and only the structure different from 1st embodiment is demonstrated in the remaining embodiment.

[0020] The figures are diagrammatic and not shown to scale. For the accuracy and convenience of the drawings, the relative sizes and ratios of the parts in the drawings are shown in exaggerated or reduced sizes, and any sizes are only exemplary rather than limiting. And the same reference numerals are used for the same structure, element or component shown in two or more figures to denote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com