Air-conditioning temperature zone layered variable porosity honeycomb structure regenerator

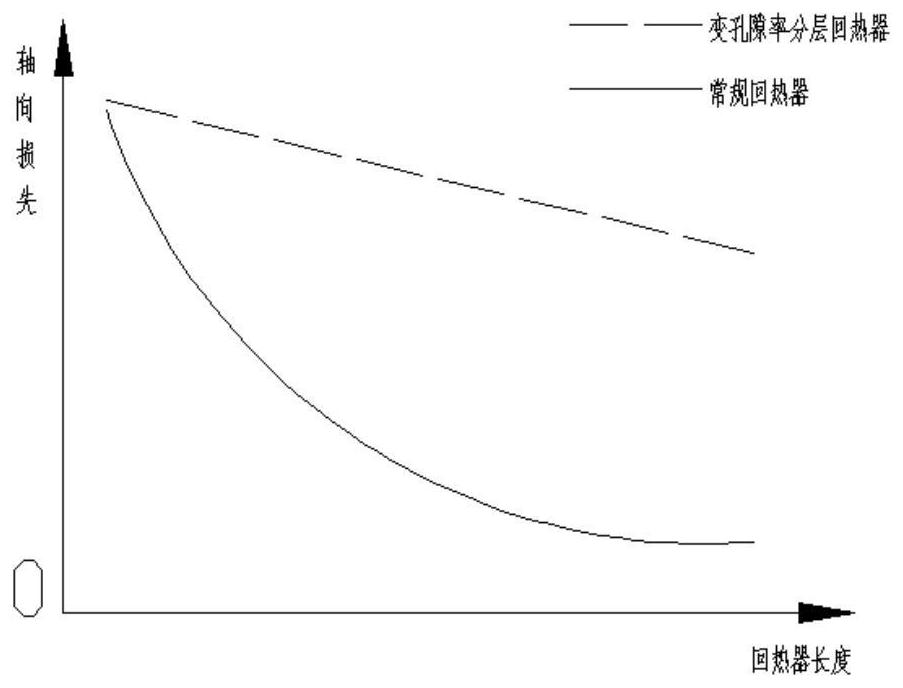

A technology of honeycomb structure and regenerator, which is applied in the direction of superheater, heat recovery system, energy-saving heating/cooling, etc. It can solve the problems of poor axial heat conduction ability, achieve small loss of flow resistance, optimize performance, good heat recovery and The effect of air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

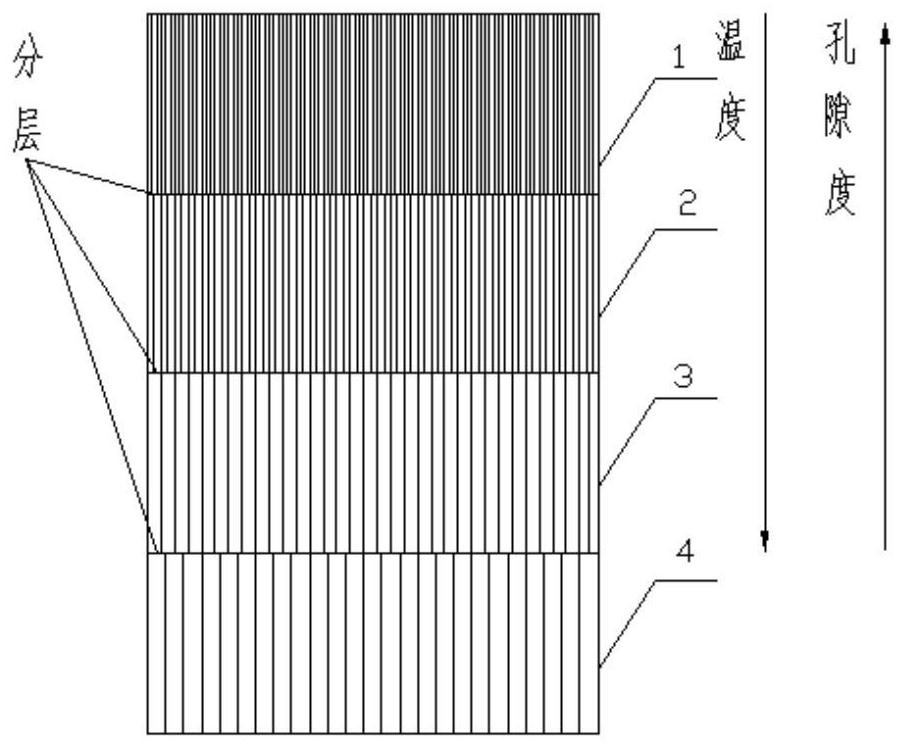

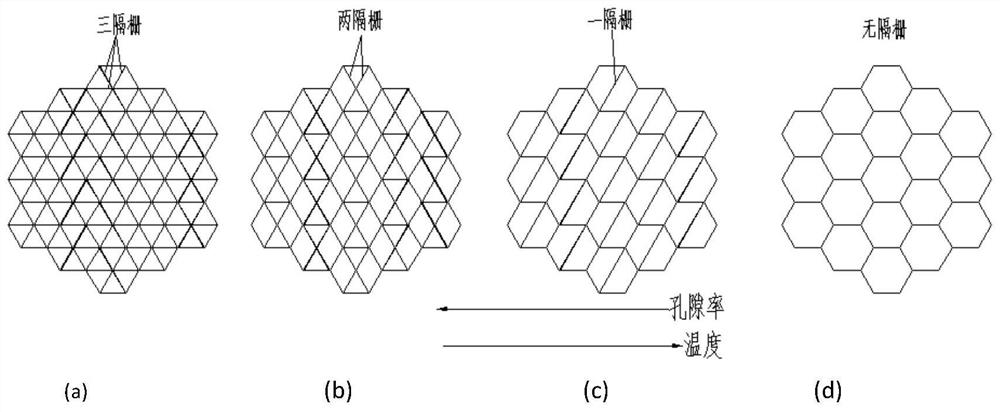

[0046] see figure 1 and figure 2 , the present invention is a variable porosity regenerator for Stirling heat pumps / refrigerators in air-conditioning temperature zones, which consists of four parts: high temperature layer 1, middle temperature layer 1, middle temperature layer 2, middle temperature layer 2 3 and low temperature layer 4. Among them, the high temperature layer 1 is connected to the hot end of the Stirling machine, the middle temperature layer 2 and the middle temperature layer 2 3 are connected to the high temperature layer 1 and the low temperature layer 4, and the low temperature layer 4 is connected to the cold end of the Stirling machine, and the working gas is absorbed at the hot end Thermal expansion, heat storage through the high temperature layer 1, middle temperature layer 1, middle temperature layer 2, and low temperature layer 4 of the regenerator, and the temperature decreases after flowing to the cold end. The working fluid is compressed at the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com