Rotary kiln device for preparing lightweight aggregate from solid waste for simulation experiment

A technology for solid waste and simulation experiments, which is applied in the field of light aggregate rotary kiln devices for the preparation of light aggregates from solid waste in simulation experiments, can solve the problems of large changes in process parameters, large differences in the roasting process between muffle furnaces and rotary kilns, and inability to reasonably Simulate the actual production of rotary kiln and other problems to achieve the effect of dynamic movement, improvement effect, and real and reliable simulation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

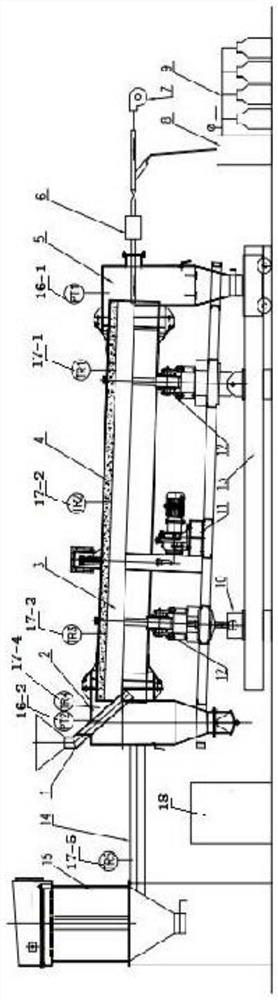

[0031] like figure 1 As shown, the rotary kiln device for preparing lightweight aggregate from solid waste in the simulation experiment of this embodiment includes a rotary kiln system and a temperature and pressure measurement and control system installed in the rotary kiln system. The head of the rotary kiln system is connected to the burner system , the tail of the rotary kiln system is connected with the flue gas purification system;

[0032] The rotary kiln system includes a rotary kiln shell 3 and a kiln head cover 5 and a kiln tail cover 2 that are respectively sealed and connected to the head and tail ends of the rotary kiln shell 3. The inside of the rotary kiln shell 3 is built with refractory Lining 4, a transmission device 11 is connected to the lower side of the rotary kiln shell 3, and the rotary kiln shell 3 is installed on a base 13;

[0033] The temperature and pressure measurement and control system includes a thermocouple and a pressure transmitter, and bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com