Optical module high and low temperature test system

An optical module testing and testing system technology, applied in the field of optical communication, can solve the problems of inconvenience that only one product can be tested at a time, the high cost of optical module testing, and the large volume of the low temperature box, so as to shorten the test waiting time. , Improve test efficiency, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

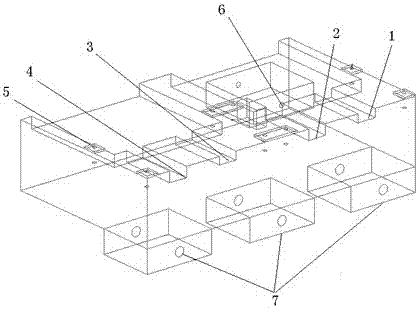

[0025] Such as figure 1 In the shown optical module test bench, an optical module test unit is arranged on the test bench, and the optical module test unit includes one XFP test unit and one SFP test unit. The XFP unit includes 1 XFP test slot 2 and 1 XFP pre-cooling slot 1. The depth of the XFP test slot 2 is half of the height of the XFP module, and its width is controlled within the positive tolerance of the XFP module width within 2mm, ensuring that the module The contact area with the test slot is the largest to achieve the best cooling effect, and it can perfectly cooperate with the Molex interface on the circuit board above. The width of XFP pre-cooling slot 1 is the same as that of XFP test slot 2, and its depth is 2mm deeper than that of XFP test slot 2, which can pre-cool the modules well. The SFP test unit includes SFP test tank 4 and SFP pre-cooling tank 3. The depth of SFP test tank 4 is half of the height of the SFP module, and its width is controlled within the...

Embodiment 2

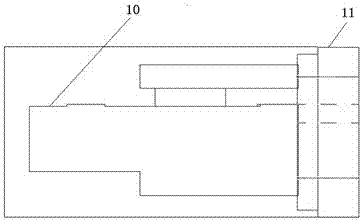

[0038] The structure of the optical module high and low temperature test system in this embodiment is basically the same as that in Embodiment 1, the difference is that: Figure 5 , 6As shown, a cooling pipeline 15 is added inside the test bench 10, and the cooling pipeline 15 is located below the optical module test unit. 17 is located inside the test platform 10 . During the low-temperature test, liquid nitrogen is input into the refrigeration pipeline 15 through the liquid nitrogen access pipeline 14, and the liquid nitrogen is discharged from the air outlet 17 through the internal circulation pipeline from the air inlet 16. Since the refrigeration pipeline 15 is located on the test bench 10, the optical module test It is directly below the unit, so it can directly cool the test unit to achieve the purpose of rapid cooling.

[0039] The invention has simple design, low cost, and is compatible with high and low temperature tests of XFP and SFP / SFP+. By setting the pre-cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com