Automatic sampling system

A technology of automatic sampling and sampling machine, which is applied in the direction of sampling devices, etc., can solve the problems of lack of representativeness, sampling results are easily affected by human factors, and manual sampling efficiency is low, so as to achieve high work efficiency, objective and effective sampling results, and improve sampling efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

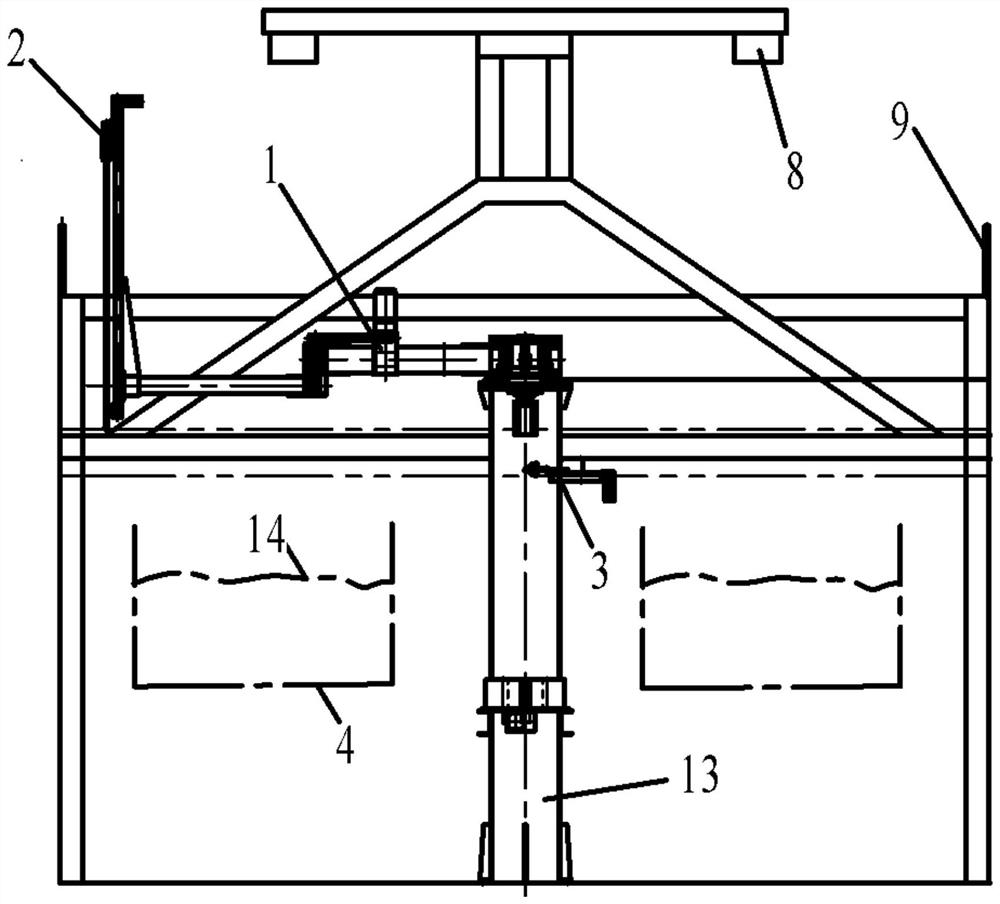

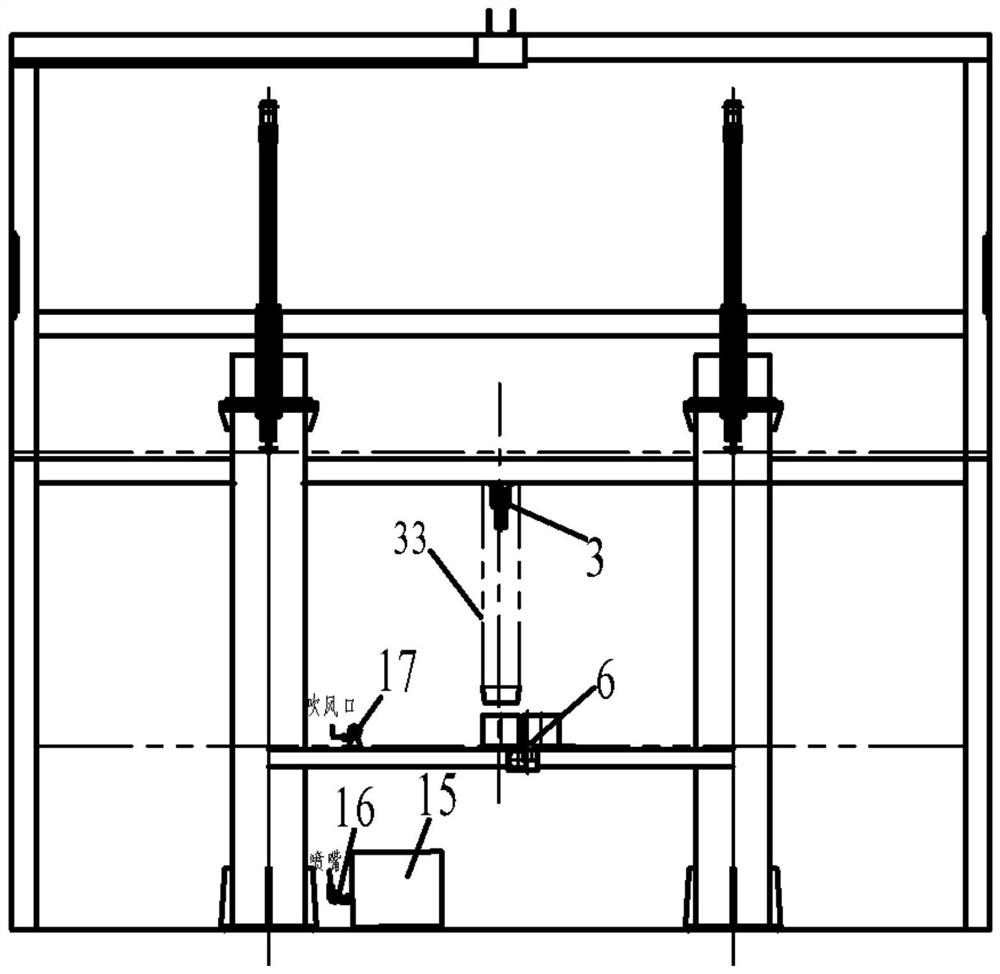

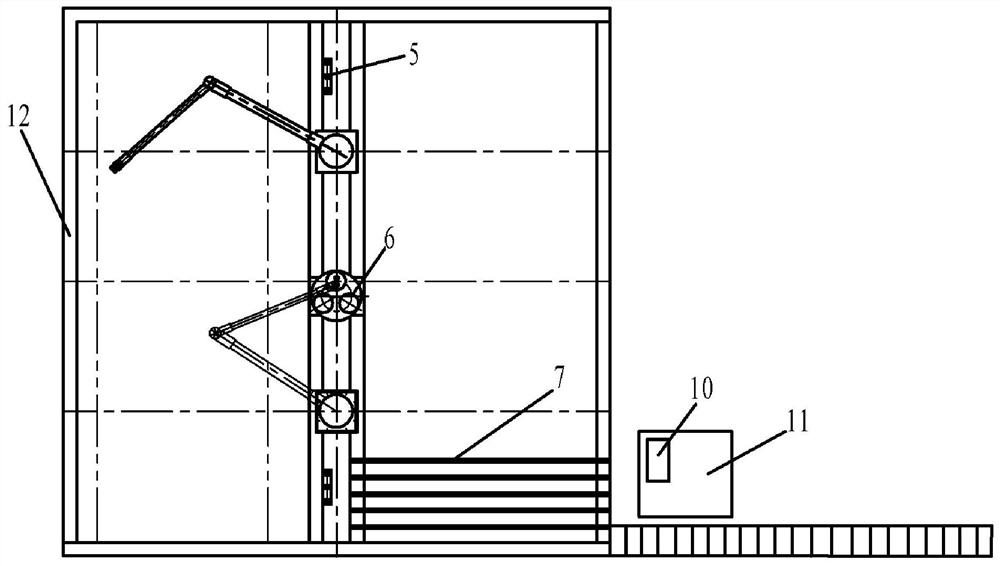

[0038] Such as Figure 1~3 As shown, a kind of automatic sampling system comprises sampling platform 12, and safety protection electronic fence 9 is installed around sampling platform 12, alarm and emergency stop when people and foreign objects enter the sampling area during normal operation, and safety protection of people and objects in the sampling area and equipment security. Above the sampling platform 12, there is a scanning device 8 for scanning and calibrating the position of the mineral material car hopper 4. The scanning device 8 scans the sampling area to calibrate the specific position of the mineral material car hopper 4, which is convenient for the automatic sampling system in the area set by the mineral material car hopper 4. The location is automatically sampled. The area where the sampling platform 12 is located is provided with a sampling station, a scraping and cleaning and air-drying station, and a receiving station. The sampling station is located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com