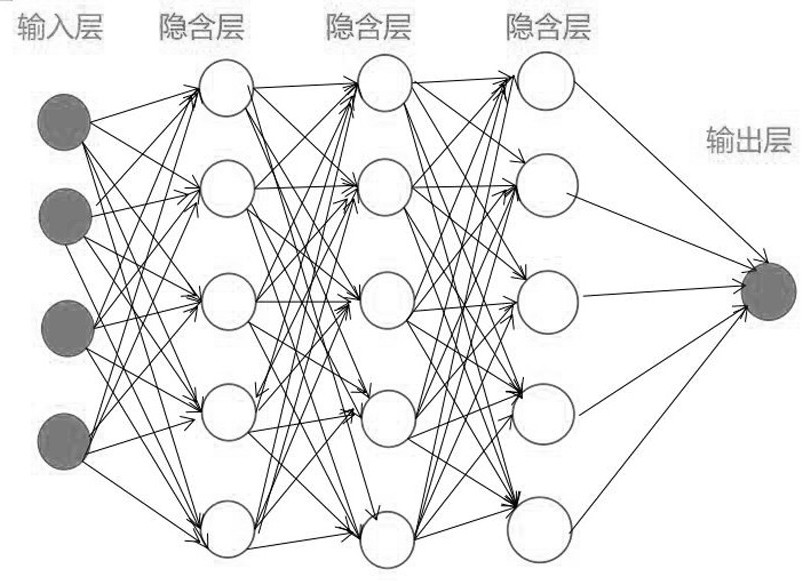

Portland cement clinker strength prediction method based on DNN neural network

A technology of portland cement and neural network, applied in the field of neural network, can solve the problems of insufficient prediction accuracy in complex scenarios and affect the prediction accuracy, achieve high market returns and environmental returns, simplify the corresponding relationship, and avoid the effects of manual testing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

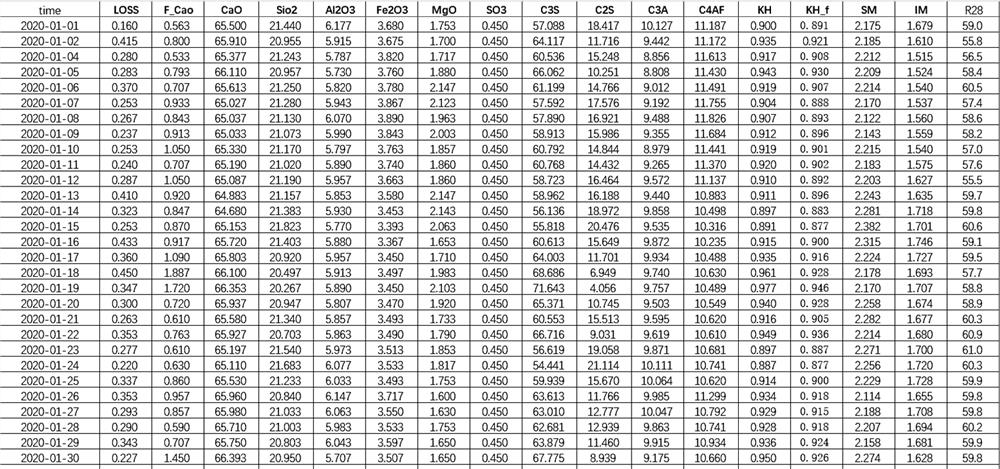

[0051] Portland cement clinker is made of raw materials mainly containing cao, sio2, A12o3, and Fe2o3, which are ground into fine powder in an appropriate proportion and burned to partially melt to obtain tricalcium silicate, dicalcium silicate, tricalcium aluminate and ferroaluminate Tetracalcium is a hydraulic gelling substance whose main mineral component is. After Portland cement clinker is ground together with an appropriate amount of gypsum, it is made into Portland cement. In the process of Portland cement production, the strength of Portland cement clinker is the foundation of cement production enterprises. If the strength of cement clinker is low, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com